Content Menu

● Understanding Common Issues in SMD Machines

● Step-by-Step Troubleshooting Process for SMD Machines

>> 1. Visual Inspection and Cleaning

>> 2. Verify Machine Calibration

>> 3. Check Solder Paste Application

>> 4. Inspect Component Feeders and Nozzles

>> 5. Analyze Reflow Profile

>> 6. Use Diagnostic Software and Logs

>> 7. Perform Component-Level Repairs

● Advanced Troubleshooting Techniques for SMD Machines

>> Thermal Imaging for Hotspot Detection

>> Vibration and Noise Analysis

>> Statistical Process Control (SPC)

>> Root Cause Analysis (RCA)

● Best Practices for SMD Machine Repair and Maintenance

● Conclusion

● FAQ

>> 1. How do I fix solder bridging on my SMD machine?

>> 2. What should I do if my SMD machine fails to pick up components?

>> 3. How can I improve fiducial recognition accuracy?

>> 4. What causes insufficient solder on SMD joints?

>> 5. How do I safely remove and replace an SMD component?

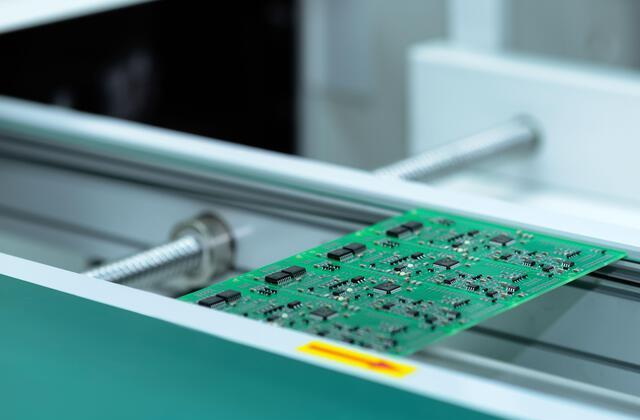

Surface Mount Device (SMD) machines are indispensable in today's electronics manufacturing industry. These machines enable the precise placement of tiny electronic components onto printed circuit boards (PCBs), supporting high-volume and high-precision assembly lines. However, like all complex machinery, SMD machines occasionally experience faults or performance issues that can disrupt production quality and efficiency. Effective troubleshooting and timely SMD machine repair are essential to minimize downtime, reduce defects, and maintain optimal output.

In this comprehensive guide, we will explore common problems encountered with SMD machines, step-by-step troubleshooting techniques, and best practices for repair and maintenance. Whether you are a technician, engineer, or operator, this article will help you understand how to identify issues quickly and implement effective solutions.

Understanding Common Issues in SMD Machines

Before troubleshooting, it is important to recognize the typical problems that arise in SMD machines. These issues often manifest as defects on the PCB or operational errors reported by the machine. Common problems include:

- Component Placement Errors: Components may be misplaced, rotated incorrectly, or skewed. This is often caused by calibration errors, mechanical wear, or feeder malfunctions.

- Soldering Defects: Defects such as solder bridging (short circuits), insufficient solder, tombstoning (component lifting on one side), and solder balls can occur due to issues in solder paste printing or reflow.

- Pick-up and Release Failures: Vacuum nozzles or feeders may fail to pick up or release components properly, causing production stops or misplacements.

- Fiducial Recognition Errors: Fiducials (reference marks on PCBs) are used for alignment. If the machine cannot accurately detect them, placement accuracy suffers.

- Mechanical Failures: Wear and tear on belts, motors, nozzles, and feeders can cause operational faults and reduce machine reliability.

Understanding these common failure modes is the first step toward effective troubleshooting and SMD machine repair.

Step-by-Step Troubleshooting Process for SMD Machines

1. Visual Inspection and Cleaning

Start with a thorough visual inspection of the machine and the PCB:

- Stencil and Nozzle Cleaning: Dirt, solder paste residue, or oxidation on the stencil apertures can block solder paste flow, causing insufficient solder deposits or bridging. Clean the stencil regularly with approved solvents and tools.

- Vacuum Nozzle Condition: Inspect vacuum nozzles for cracks, wear, or clogging. Damaged nozzles reduce vacuum pressure and cause pick-up failures.

- PCB Surface: Check the PCB for contamination such as oils or dust that can affect solder paste adhesion or component placement.

Regular cleaning and inspection prevent many common issues and are a vital part of SMD machine repair.

2. Verify Machine Calibration

Accurate calibration is fundamental to precise component placement:

- Stencil Alignment: Misalignment between the stencil and PCB pads leads to solder bridging or missing solder. Use the machine's alignment tools to recalibrate stencil positioning.

- Fiducial Recognition: Clean camera lenses and verify software settings. Recalibrate the vision system if fiducial detection is inconsistent.

- Placement Accuracy: Run test cycles and inspect component positions. Adjust mechanical offsets or recalibrate the XY axes if components are misplaced.

Proper calibration ensures the machine operates within design tolerances, reducing defects and rework.

3. Check Solder Paste Application

Solder paste application is critical for robust solder joints:

- Solder Paste Quality: Use fresh solder paste stored under recommended conditions. Paste that is old or improperly stored can lose viscosity and cause defects.

- Stencil Aperture Size: Aperture size controls paste volume. Oversized apertures cause bridging; undersized apertures cause insufficient solder.

- Printing Parameters: Adjust squeegee pressure, speed, and angle to ensure even paste deposition. Too fast or too slow printing can cause uneven paste layers.

- Metal-to-Flux Ratio: The balance between metal particles and flux in solder paste affects wetting and joint strength.

Monitoring and optimizing solder paste printing reduces soldering defects and improves yield.

4. Inspect Component Feeders and Nozzles

Reliable component feeding and pick-up are essential:

- Feeder Condition: Inspect feeders for wear or damage. Replace worn tapes or parts to avoid feeding jams.

- Vacuum Pressure: Check vacuum pumps and tubing for leaks or blockages. Insufficient vacuum reduces pick-up reliability.

- Nozzle Maintenance: Clean nozzles regularly and replace damaged ones. Nozzle shape and size must match component dimensions.

- Vibration Settings: For vibration feeders, adjust amplitude and frequency to ensure smooth component delivery.

Proper maintenance of feeders and nozzles is a key aspect of SMD machine repair that prevents frequent stoppages.

5. Analyze Reflow Profile

The reflow soldering process solidifies solder paste into reliable joints:

- Temperature Profiling: Use thermal profiling tools to measure PCB temperature during reflow. Profiles should follow recommended preheat, soak, reflow, and cooling stages.

- Avoid Excessive Heat: Overheating can cause solder paste slump, tombstoning, or component damage.

- Optimize Conveyor Speed: Adjust conveyor speed through the oven to match the thermal profile requirements.

- Check Oven Uniformity: Ensure the oven provides even heat distribution to avoid cold spots or overheating.

Optimizing the reflow profile improves solder joint quality and reduces defects.

6. Use Diagnostic Software and Logs

Modern SMD machines come equipped with diagnostic tools:

- Run Built-in Diagnostics: Use the machine's self-test functions to check sensors, motors, and other components.

- Analyze Error Logs: Review error history to identify recurring issues or patterns.

- Firmware Updates: Keep the machine's firmware and software up to date to fix bugs and improve performance.

Utilizing diagnostic tools accelerates problem identification and supports effective SMD machine repair.

7. Perform Component-Level Repairs

Sometimes, defective PCBs or components require repair:

- Hot Air Rework: Use hot air rework stations to safely remove and replace SMD components without damaging the PCB.

- Flux Application: Apply flux to pads before soldering to improve wetting and reduce solder defects.

- Pad Cleaning: Use solder braid or wick to remove excess solder and clean pads before rework.

- Protect Adjacent Components: Use Kapton tape or shields to protect nearby components from heat during repair.

Component-level repair helps salvage valuable PCBs and reduces scrap rates.

Advanced Troubleshooting Techniques for SMD Machines

Beyond basic troubleshooting, advanced techniques can help diagnose and resolve more complex issues in your SMD machine:

Thermal Imaging for Hotspot Detection

Using a thermal imaging camera during reflow can identify hotspots or uneven heating on the PCB. Hotspots may cause solder defects or damage components. This technique helps optimize oven settings and detect mechanical issues causing uneven heat distribution.

Vibration and Noise Analysis

Unusual vibrations or noises during machine operation often indicate mechanical problems such as misaligned belts, worn bearings, or loose components. Using vibration analysis tools can help pinpoint these issues early, allowing for timely SMD machine repair before failures occur.

Statistical Process Control (SPC)

Implementing SPC techniques to monitor key parameters such as placement accuracy, solder paste volume, and defect rates helps identify trends and deviations. Early detection of process drift allows corrective actions before defects increase.

Root Cause Analysis (RCA)

When recurring problems arise, conduct a thorough root cause analysis to identify underlying causes rather than symptoms. Techniques such as the “5 Whys” or fishbone diagrams can be used to systematically investigate and resolve persistent issues.

Best Practices for SMD Machine Repair and Maintenance

To keep your SMD machine running smoothly and reduce the need for emergency repairs, follow these best practices:

- Regular Maintenance Schedule: Establish daily, weekly, and monthly maintenance routines including cleaning, lubrication, and inspection of mechanical parts.

- Operator Training: Train operators and technicians on proper machine handling, troubleshooting, and preventive maintenance techniques.

- Spare Parts Inventory: Maintain an inventory of critical spare parts such as nozzles, feeders, vacuum pumps, belts, and sensors to minimize downtime during repairs.

- Documentation: Keep detailed records of all repairs, adjustments, and maintenance activities for future reference and continuous improvement.

- Environmental Control: Maintain stable temperature and humidity in the production area to prevent solder paste degradation and machine component wear.

Implementing these practices enhances machine reliability and production quality.

Conclusion

Effectively troubleshooting your SMD machine requires a systematic approach that combines visual inspection, calibration verification, solder paste control, component feeder maintenance, and reflow profile optimization. Many common defects and machine errors can be prevented or rapidly resolved by following these steps. Regular preventive maintenance and timely SMD machine repair are essential to minimize downtime, reduce defects, and ensure consistent high-quality PCB assembly.

Advanced diagnostic techniques such as thermal imaging, vibration analysis, and statistical process control further enhance your ability to maintain and repair SMD machines efficiently. By understanding the typical failure modes and applying targeted repair strategies, technicians and operators can maximize the performance and longevity of their SMD machines, ultimately improving manufacturing efficiency and product reliability.

FAQ

1. How do I fix solder bridging on my SMD machine?

Solder bridging is often caused by excessive solder paste or stencil misalignment. To fix it, reduce stencil aperture size by about 10%, ensure the stencil is clean, adjust the solder paste metal-to-flux ratio, and verify that component placement pressure and alignment are accurate.

2. What should I do if my SMD machine fails to pick up components?

Check the vacuum pressure and inspect nozzles for damage or clogging. Replace worn nozzles, clean the vacuum system, and verify that feeders are functioning correctly. Adjust vibration settings if applicable to improve component feeding.

3. How can I improve fiducial recognition accuracy?

Regularly clean camera lenses and recalibrate the fiducial recognition system. Update the machine's software if needed and ensure PCBs are properly secured and free from contaminants that could interfere with recognition.

4. What causes insufficient solder on SMD joints?

Insufficient solder can result from blocked stencil apertures, low solder paste viscosity, high squeegee speed during printing, or inadequate solder paste volume. Cleaning the stencil, adjusting printing parameters, and using fresh solder paste can resolve this issue.

5. How do I safely remove and replace an SMD component?

Use a hot air rework station to evenly heat the solder joints until the solder liquefies. Gently lift the component with tweezers, clean the pads with flux and solder braid, then place the new component and carefully reflow the solder.