Content Menu

● Introduction to SMD Rework

>> Key Tools for SMD Rework

● The Four Stages of Hot Air Rework

>> 1. Preheat Stage

>> 2. Soak Stage

>> 3. Reflow Stage

>> 4. Cooling Stage

● Best Practices for Using a Hot Air Gun

>> Adjusting Temperature and Airflow

>> Handling Components

>> Safety Precautions

● Tips for Optimizing SMD Rework

>> Use of Preheaters

>> Choosing the Right SMD Rework Station

>> Importance of Digital Microscopes

>> Advanced Techniques for Complex Components

>> Training and Practice

● Common Challenges in SMD Rework

>> Component Damage

>> Solder Bridging

>> PCB Warping

● Conclusion

● Frequently Asked Questions

>> 1. What are the key tools needed for SMD rework?

>> 2. How do I adjust the temperature and airflow on a hot air gun?

>> 3. What are the stages of the thermal profile in SMD rework?

>> 4. Why is it important to use a preheater in SMD rework?

>> 5. How can I prevent overheating during SMD rework?

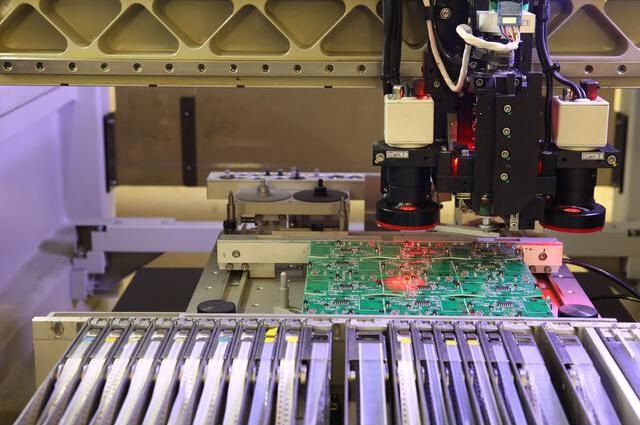

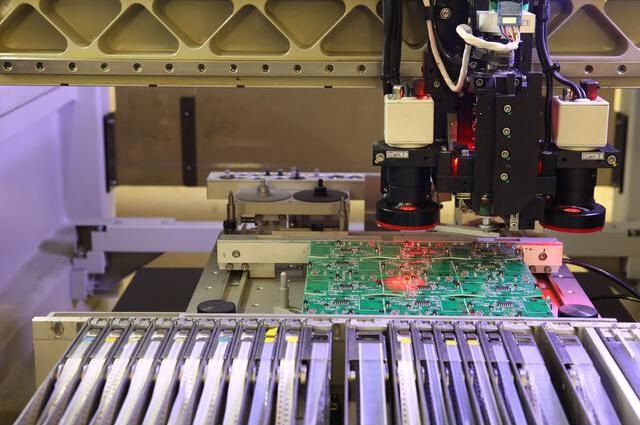

Achieving better results with a hot air gun for SMD (Surface Mount Device) rework involves understanding the principles of thermal management, selecting the right tools, and mastering the techniques involved in the process. SMD rework is a critical skill in electronics repair and assembly, requiring precision and care to avoid damaging components or the PCB (Printed Circuit Board). In this article, we will delve into the best practices for using a hot air gun, the stages of the rework process, and tips for optimizing your workflow.

Introduction to SMD Rework

SMD rework is the process of repairing or replacing surface-mounted components on a PCB. This involves desoldering the existing component and soldering a new one in its place. The use of a hot air gun is essential for this process, as it provides the controlled heat necessary to melt solder without damaging the components or the board.

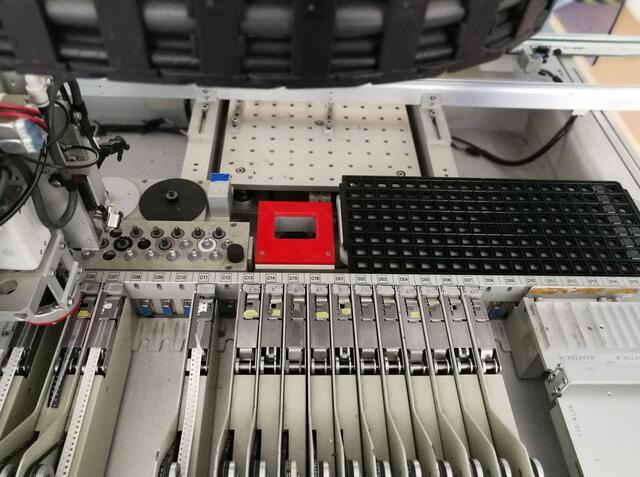

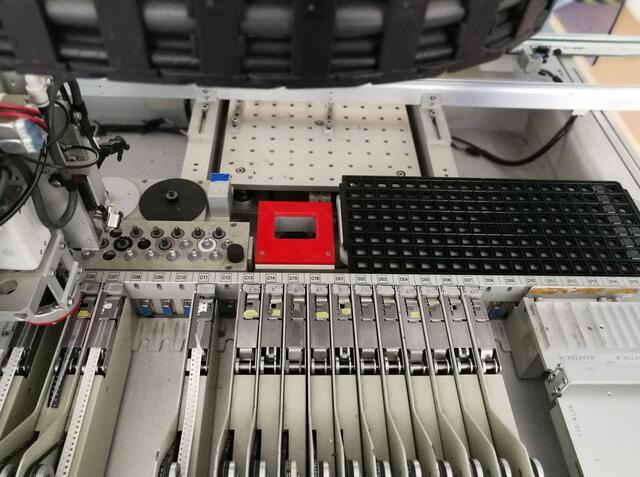

Key Tools for SMD Rework

- Hot Air Gun: This is the primary tool for SMD rework. It provides a controlled flow of hot air that can be directed at specific components to melt solder.

- Digital Microscope: Useful for inspecting small components and ensuring they are properly aligned.

- Tweezers: Non-magnetic tweezers are essential for handling and placing SMD components.

- Soldering Paste: Used to facilitate soldering by providing a flux that helps remove oxidation from component leads and pads.

The Four Stages of Hot Air Rework

Understanding the thermal profile of the rework process is crucial for achieving successful results. The process typically involves four stages: preheat, soak, reflow, and cooling.

1. Preheat Stage

In this initial stage, the PCB and components are heated to a temperature that prepares them for the rework process. This stage is critical for preventing thermal shock to sensitive components. A preheater may be used to assist in this process, ensuring a controlled temperature ramp-up rate, typically not exceeding 3.0°C/second.

2. Soak Stage

During the soak stage, the temperature is maintained at a level that allows the heat to penetrate the component and PCB evenly. This stage helps activate flux and remove oxidation, ensuring a clean solder joint. It is essential to maintain a slow and controlled temperature increase to avoid thermal stress.

3. Reflow Stage

In this stage, the component is heated to a temperature above the solder's melting point. For lead-free solder, this is typically around 217°C. The solder must remain in a liquid state for a specified time, known as "Time Above Liquidus," which varies depending on the manufacturer's specifications.

4. Cooling Stage

After reflow, the component and PCB are slowly cooled to prevent thermal shock. This stage is crucial for ensuring the solder solidifies properly and for extending the life of the heating element in the hot air gun.

Best Practices for Using a Hot Air Gun

Adjusting Temperature and Airflow

- Temperature: Set the temperature slightly above the melting point of the solder. For most tasks, a range of 300°C to 350°C is suitable.

- Airflow: Adjust the airflow to be strong enough to melt the solder but gentle enough not to displace small components. Start with lower settings and increase as needed.

Handling Components

- Use non-magnetic tweezers to handle SMD components to prevent damage from magnetic fields.

- Ensure the PCB is placed on a heat-resistant surface to prevent damage during the rework process.

Safety Precautions

- Always keep the hot air gun moving to avoid concentrating heat on a single spot, which can damage components or the PCB.

- Monitor for signs of overheating, such as smoke or discoloration, and adjust the temperature accordingly.

Tips for Optimizing SMD Rework

Use of Preheaters

Preheaters can be invaluable in the preheat stage, ensuring that the PCB and components are uniformly heated. This helps prevent thermal shock and ensures a successful rework process.

Choosing the Right SMD Rework Station

Select a rework station that offers adjustable temperature and airflow control. This flexibility is crucial for adapting to different types of components and solder. A good rework station should also include features such as a digital display for precise temperature control and a robust build to withstand frequent use.

Importance of Digital Microscopes

A digital microscope can significantly enhance your ability to inspect and place SMD components accurately. It allows for high-quality imaging and can be indispensable for complex rework tasks. Features to look for in a digital microscope include high magnification, good lighting options, and the ability to capture images or videos for documentation.

Advanced Techniques for Complex Components

For more complex components, such as BGA (Ball Grid Array) devices, additional techniques may be required. This includes using specialized nozzles for the hot air gun to focus heat directly on the component without affecting surrounding components. It may also involve using specialized tools to remove and replace the component safely.

Training and Practice

Like any skill, mastering SMD rework requires practice. Start with simple components and gradually move to more complex ones. Training videos and tutorials can provide valuable insights into techniques and best practices.

Common Challenges in SMD Rework

Component Damage

One of the most common challenges is preventing damage to components during the rework process. This can be avoided by using the right temperature and airflow settings and ensuring that the component is properly secured during heating.

Solder Bridging

Solder bridging occurs when solder flows between two or more pads, creating an unintended electrical connection. This can be prevented by using the right amount of solder paste and ensuring that the component is aligned correctly before reflow.

PCB Warping

PCB warping can occur if the board is heated unevenly. Using a preheater and ensuring that the PCB is supported during the rework process can help prevent this issue.

Conclusion

Achieving better results with a hot air gun for SMD rework requires a combination of the right tools, a thorough understanding of the thermal profile, and adherence to best practices. By mastering these techniques and using high-quality equipment, you can ensure reliable and efficient electronics repair and assembly.

Frequently Asked Questions

1. What are the key tools needed for SMD rework?

The key tools for SMD rework include a hot air gun, digital microscope, non-magnetic tweezers, and soldering paste. Each tool plays a crucial role in ensuring precision and safety during the rework process.

2. How do I adjust the temperature and airflow on a hot air gun?

Adjust the temperature to be slightly above the solder's melting point, typically between 300°C and 350°C. Adjust the airflow to be strong enough to melt the solder but gentle enough not to displace components. Start with lower settings and increase as needed.

3. What are the stages of the thermal profile in SMD rework?

The stages include preheat, soak, reflow, and cooling. Each stage is critical for ensuring a successful rework process without damaging components or the PCB.

4. Why is it important to use a preheater in SMD rework?

A preheater helps ensure that the PCB and components are uniformly heated, preventing thermal shock and ensuring a successful rework process. It assists in maintaining a controlled temperature ramp-up rate.

5. How can I prevent overheating during SMD rework?

To prevent overheating, keep the hot air gun moving to avoid concentrating heat on a single spot. Monitor for signs of overheating, such as smoke or discoloration, and adjust the temperature accordingly.