Content Menu

● Understanding Surface Mount Assembly

>> What is Surface Mount Assembly?

>> The Importance of Wholesale Surface Mount Assembly

● Benefits of Wholesale Surface Mount Assembly

>> Increased Production Speed

>> Cost-Effectiveness

>> Enhanced Design Flexibility

>> Improved Quality and Reliability

>> Space Efficiency

● The Process of Wholesale Surface Mount Assembly

>> Step 1: Design and Prototyping

>> Step 2: Solder Paste Application

>> Step 3: Component Placement

>> Step 4: Reflow Soldering

>> Step 5: Inspection and Testing

● Challenges in Wholesale Surface Mount Assembly

● Conclusion

● FAQ

>> 1. What is the difference between surface mount assembly and through-hole assembly?

>> 2. How does wholesale surface mount assembly reduce costs?

>> 3. What types of components can be used in surface mount assembly?

>> 4. How does quality control work in wholesale surface mount assembly?

>> 5. What are the initial investments required for wholesale surface mount assembly?

In the fast-paced world of electronics manufacturing, efficiency and scalability are paramount. One of the most effective methods to achieve these goals is through wholesale surface mount assembly (SMA). This article explores how wholesale surface mount assembly can significantly enhance the scalability of electronics manufacturing, detailing its benefits, processes, and implications for businesses in the industry.

Understanding Surface Mount Assembly

What is Surface Mount Assembly?

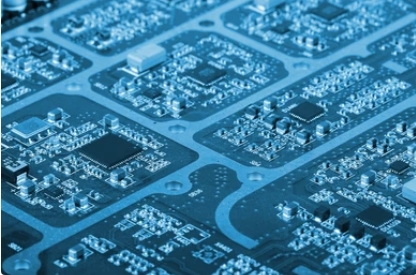

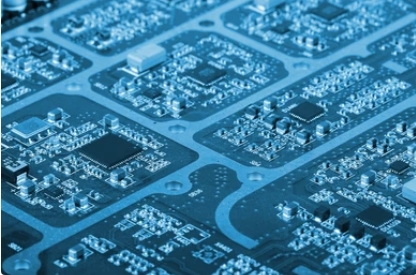

Surface mount assembly is a method of mounting electronic components directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole technology, where components are inserted into holes in the PCB, surface mount technology (SMT) allows for a more compact design, enabling manufacturers to produce smaller and more efficient electronic devices.

The Importance of Wholesale Surface Mount Assembly

Wholesale surface mount assembly refers to the bulk production of electronic components using SMT techniques. This approach is particularly beneficial for companies looking to scale their operations, as it allows for high-volume production with reduced costs and increased speed. By leveraging wholesale SMA, manufacturers can meet growing demand without compromising on quality or performance.

Benefits of Wholesale Surface Mount Assembly

Increased Production Speed

One of the primary advantages of wholesale surface mount assembly is the speed at which products can be manufactured. Automated pick-and-place machines can rapidly position components on PCBs, significantly reducing assembly time compared to manual methods. This efficiency is crucial for companies aiming to bring products to market quickly.

Cost-Effectiveness

Wholesale SMA can lead to substantial cost savings. By producing components in bulk, manufacturers can take advantage of economies of scale, reducing the per-unit cost of production. Additionally, the reduced labor costs associated with automation further enhance profitability.

Enhanced Design Flexibility

Surface mount technology allows for greater design flexibility. Manufacturers can utilize a wider variety of components, including smaller and more complex parts that are not feasible with traditional methods. This flexibility enables the creation of innovative products that can meet diverse consumer needs.

Improved Quality and Reliability

The precision of automated surface mount assembly processes leads to higher quality and reliability in electronic products. Automated systems minimize human error, ensuring that components are placed accurately and consistently. This reliability is essential for maintaining customer satisfaction and brand reputation.

Space Efficiency

SMA allows for a more compact design of electronic devices. By mounting components directly onto the surface of PCBs, manufacturers can save space, which is particularly important in the production of portable and compact devices. This space efficiency can also lead to reduced shipping costs and improved inventory management.

The Process of Wholesale Surface Mount Assembly

Step 1: Design and Prototyping

The first step in the wholesale surface mount assembly process involves designing the PCB layout. This includes determining the placement of components and ensuring that the design meets the specifications for SMT. Prototyping is often conducted to test the design before moving to mass production.

Step 2: Solder Paste Application

Once the design is finalized, solder paste is applied to the PCB. This paste is crucial for ensuring that components adhere properly during the assembly process. The application is typically done using a stencil to ensure precision.

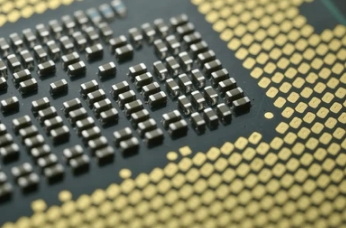

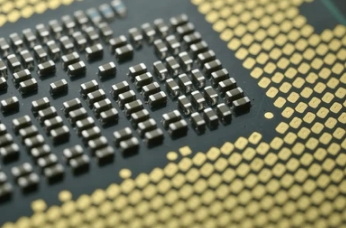

Step 3: Component Placement

Automated pick-and-place machines are used to position the components onto the solder paste. These machines can handle a wide variety of component sizes and types, making them ideal for wholesale production.

Step 4: Reflow Soldering

After the components are placed, the PCB is subjected to a reflow soldering process. This involves heating the board to melt the solder paste, which then solidifies to create a strong electrical connection between the components and the PCB.

Step 5: Inspection and Testing

Quality control is a critical aspect of wholesale surface mount assembly. Automated optical inspection (AOI) systems are often employed to check for defects in the assembly process. Additionally, functional testing ensures that the assembled products meet performance standards.

Challenges in Wholesale Surface Mount Assembly

While wholesale surface mount assembly offers numerous benefits, it is not without its challenges. Manufacturers must navigate issues such as component sourcing, managing supply chain logistics, and ensuring compliance with industry standards. Additionally, the initial investment in automated equipment can be significant, although it often pays off in the long run through increased efficiency and reduced labor costs.

Conclusion

Wholesale surface mount assembly is a powerful tool for scaling electronics manufacturing. By enhancing production speed, reducing costs, and improving quality, this method enables manufacturers to meet the demands of a rapidly evolving market. As technology continues to advance, the importance of efficient and effective assembly processes will only grow, making wholesale surface mount assembly an essential component of successful electronics manufacturing strategies.

FAQ

1. What is the difference between surface mount assembly and through-hole assembly?

Surface mount assembly involves mounting components directly onto the surface of a PCB, while through-hole assembly requires components to be inserted into holes in the PCB. SMA is generally faster and allows for more compact designs.

2. How does wholesale surface mount assembly reduce costs?

Wholesale surface mount assembly reduces costs through economies of scale, as producing components in bulk lowers the per-unit cost. Additionally, automation reduces labor costs associated with manual assembly.

3. What types of components can be used in surface mount assembly?

A wide variety of components can be used in surface mount assembly, including resistors, capacitors, integrated circuits, and more. The flexibility of SMA allows for the use of smaller and more complex components.

4. How does quality control work in wholesale surface mount assembly?

Quality control in wholesale surface mount assembly typically involves automated optical inspection (AOI) to detect defects, as well as functional testing to ensure that assembled products meet performance standards.

5. What are the initial investments required for wholesale surface mount assembly?

Initial investments for wholesale surface mount assembly can include the cost of automated pick-and-place machines, reflow ovens, and quality inspection systems. While these costs can be significant, they are often offset by the increased efficiency and reduced labor costs over time.