Content Menu

● Introduction to Step Stencil SMT

>> Types of Step Stencils

● Applications of Step Stencil SMT

● Benefits of Step Stencil SMT

● Manufacturing Processes for Step Stencils

● Challenges and Considerations

● Role of Stencils in SMT Efficiency

>> Ensuring Accuracy and Precision

>> Improving Production Efficiency

● Evolution of SMT and the Role of Step Stencils

>> Miniaturization and Increased Functionality

>> High-Density Assemblies

● Future of Step Stencil Technology

● Emerging Applications of Step Stencils

>> IoT Devices

>> Automotive Electronics

● Industry Applications of SMT

>> Automotive Industry

>> Medical Equipment Manufacturing

>> Telecommunications

>> Consumer Electronics

● Conclusion

● FAQs

>> 1. What are the primary types of step stencils used in SMT?

>> 2. How do step stencils improve PCB production efficiency?

>> 3. What manufacturing techniques are used to create step stencils?

>> 4. What are the benefits of using micromachining for step stencil production?

>> 5. How do step stencils help in managing solder paste volume for mixed-component PCBs?

● Citations:

In the realm of Surface Mount Technology (SMT), optimizing the production line is crucial for efficiency, quality, and cost-effectiveness. One key component in achieving this optimization is the step stencil SMT, which plays a pivotal role in managing solder paste volumes for both large and small SMT components. This article delves into the world of step stencils, exploring their types, applications, benefits, and how they can enhance your PCB production line.

Introduction to Step Stencil SMT

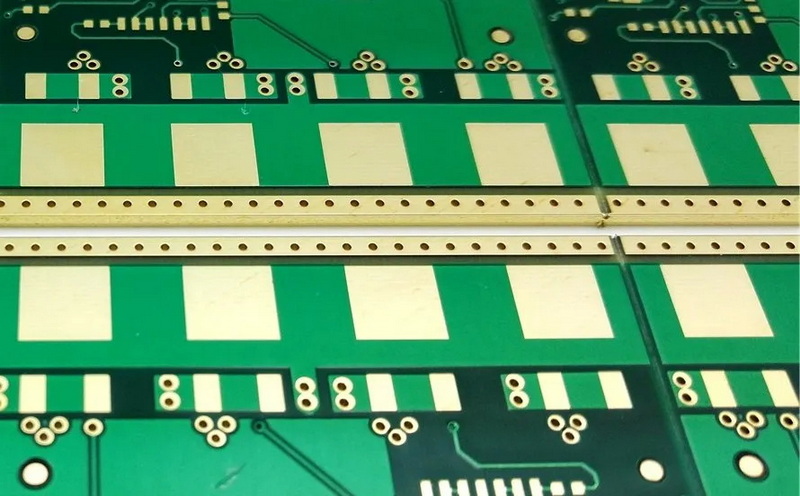

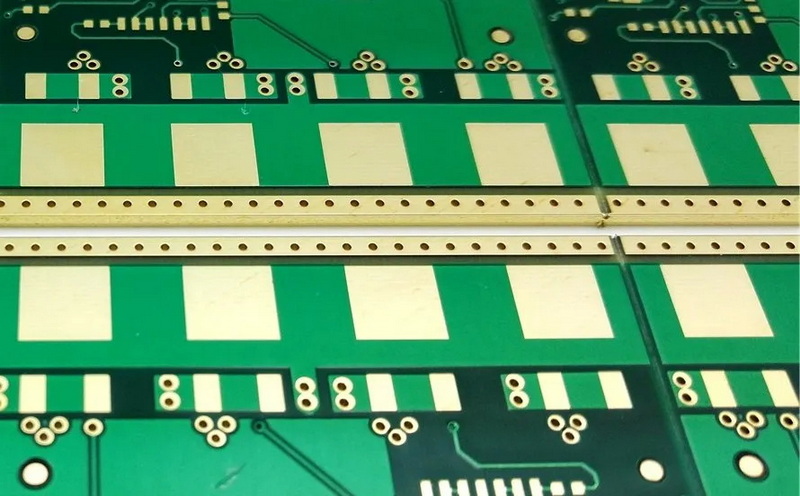

Step stencils are specialized stencils designed to accommodate the varying solder paste requirements of different components on a single PCB. Unlike traditional stencils, which have a uniform thickness, step stencils vary in thickness across different areas to ensure optimal solder paste deposition for each component type. This is particularly important in modern electronics manufacturing, where PCBs often feature a mix of large and small components, such as BGAs, QFPs, and 0402 capacitors.

Types of Step Stencils

There are primarily two types of step stencils: step-up and step-down stencils.

- Step-Up Stencils: These are used when a PCB contains mostly small components with a few large ones. The stencil starts with a thin base (e.g., 0.1 mm) and includes thicker areas (e.g., 0.15 mm) for the larger components. This design ensures that the larger components receive sufficient solder paste while minimizing excess paste on smaller components.

- Step-Down Stencils: Conversely, these are ideal for PCBs with many large components and a few small ones. The stencil begins with a thicker base (e.g., 0.15 mm) and includes thinner areas (e.g., 0.1 mm) for the smaller components. This setup helps in reducing solder paste volume for smaller components, preventing potential short circuits.

Applications of Step Stencil SMT

Step stencils are versatile and can be applied in various scenarios:

- Mixed Component PCBs: They are essential for boards that contain a mix of large and small SMT components. By adjusting the solder paste volume according to component size, step stencils ensure that each component receives the right amount of solder for reliable soldering.

- Complex PCB Designs: In designs with raised areas or irregularities, step stencils can include relief cavities to accommodate these features, ensuring smooth solder paste application around stickers or labels.

- High-Density Assemblies: For high-density PCBs with components like BGAs and fine-pitch QFPs, step stencils help manage solder paste volumes precisely, reducing defects and improving yield.

Benefits of Step Stencil SMT

The use of step stencils offers several benefits in PCB production:

- Efficient Solder Paste Management: By varying the stencil thickness, step stencils ensure that each component receives the optimal amount of solder paste, reducing waste and improving solder joint quality.

- Reduced Production Time: Step stencils eliminate the need for multiple print processes, as they can handle different component types in a single pass. This streamlines the assembly process, saving time and resources.

- Cost Savings: The ability to reuse step stencils by replacing step areas reduces the overall cost of stencil production and maintenance.

Manufacturing Processes for Step Stencils

Step stencils can be manufactured using various techniques:

- Chemical Etching: This process involves chemically removing material to create steps, which is cost-effective but may lack precision.

- Laser Cutting and Welding: This method provides high precision and is used to create complex step designs by welding different thicknesses of material together.

- Micromachining (Micromilling): Offers the highest precision and flexibility, allowing for complex shapes and profiles without distortion or burrs.

Challenges and Considerations

While step stencils offer numerous advantages, there are challenges to consider:

- Design Complexity: The design of step stencils requires careful planning to ensure that the stencil thickness matches the component requirements accurately.

- Manufacturing Precision: The precision of the manufacturing process is crucial to ensure that the stencil steps are accurate and consistent.

- Squeegee Parameters: The squeegee speed, angle, and pressure must be optimized to ensure effective solder paste transfer across different stencil thicknesses.

Role of Stencils in SMT Efficiency

Stencils, including step stencils, play a critical role in enhancing SMT efficiency. They enable precise and consistent solder paste deposition, which is essential for maintaining high product quality and maximizing yield. The use of stencils in SMT dramatically boosts production efficiency by allowing for repeated use across hundreds or thousands of boards, thereby speeding up the manufacturing process.

Ensuring Accuracy and Precision

One of the primary functions of a stencil is to provide accuracy in solder paste application. As component sizes on modern PCBs become smaller and more complex, the need for precise paste deposition is critical. A high-quality stencil ensures that the correct amount of solder is applied in the right places, reducing errors like bridging or insufficient solder.

Improving Production Efficiency

The automation provided by stencils significantly improves production efficiency compared to manual methods. Stencils offer faster throughput and help streamline high-volume production lines, making them indispensable in modern electronics manufacturing.

Evolution of SMT and the Role of Step Stencils

The landscape of electronics manufacturing has undergone a profound transformation since the advent of SMT. This technology has enabled the placement of components directly onto the surface of PCBs, facilitating miniaturization and increased component density. Step stencils have evolved to meet the demands of this complex environment by providing a flexible solution for managing solder paste volumes across diverse component types.

Miniaturization and Increased Functionality

SMT allows for the use of smaller components and achieves higher component densities on PCBs. This miniaturization is not merely about shrinking physical dimensions; it's about packing more functionality into a given space. As components become smaller, the precision required for solder paste application increases, making step stencils an essential tool in modern PCB assembly.

High-Density Assemblies

In high-density assemblies, where components like BGAs and fine-pitch QFPs are common, step stencils help manage solder paste volumes precisely. This precision is critical for reducing defects and improving yield, especially in complex PCB designs.

Future of Step Stencil Technology

As electronics manufacturing continues to evolve, the demand for more sophisticated and precise stencil technologies will grow. Future advancements in step stencil design and manufacturing will likely focus on improving precision, flexibility, and cost-effectiveness. Techniques such as micromachining will play a crucial role in creating complex step designs without distortion or burrs, enabling the production of high-quality stencils for increasingly complex PCBs.

Emerging Applications of Step Stencils

As technology advances, step stencils are finding new applications in emerging fields such as IoT devices and automotive electronics. These sectors require high reliability and precision, making step stencils an essential tool for ensuring consistent solder paste deposition across complex PCBs.

IoT Devices

IoT devices often feature a mix of small and large components, necessitating the use of step stencils to manage solder paste volumes effectively. The compact nature of these devices means that precise solder paste application is critical to prevent defects and ensure reliable operation.

Automotive Electronics

In automotive electronics, where reliability is paramount, step stencils play a crucial role in ensuring that PCBs meet stringent quality standards. The use of step stencils helps in managing solder paste volumes for components that must withstand harsh environmental conditions, such as high temperatures and vibrations.

Industry Applications of SMT

SMT technology is widely applied across various industries, including automotive, medical equipment, telecommunications, and consumer electronics. Each of these sectors benefits from the miniaturization and efficiency that SMT offers.

Automotive Industry

The automotive industry has heavily incorporated SMT to achieve compact designs with high performance. This includes control systems, ADAS for safety features, airbag and braking system sensors, car information systems, and battery management systems for electric vehicles[2].

Medical Equipment Manufacturing

SMT is used in medical devices due to their size, shape, complexity, and microfabrication requirements. It enables smaller and more efficient diagnostic and monitoring devices, such as portable diagnostic instruments and implantable devices like pacemakers[2].

Telecommunications

In telecommunications, SMT supports high-density circuitry for faster and more reliable communication networks. This includes 5G network infrastructure equipment and mobile communication systems[2].

Consumer Electronics

SMT plays a supportive role in the miniaturization and efficiency development of consumer electronic products, such as smartphones, smartwatches, and smart home devices[2].

Conclusion

Incorporating step stencil SMT into your PCB production line can significantly enhance efficiency, quality, and cost-effectiveness. By optimizing solder paste deposition for a wide range of components, step stencils help streamline the assembly process, reduce defects, and improve overall yield. As technology continues to advance and components become smaller and more complex, the role of step stencils will only become more critical in ensuring the reliability and performance of electronic devices.

FAQs

1. What are the primary types of step stencils used in SMT?

- The two primary types of step stencils are step-up and step-down stencils. Step-up stencils are used for PCBs with mostly small components and a few large ones, while step-down stencils are used for PCBs with many large components and a few small ones.

2. How do step stencils improve PCB production efficiency?

- Step stencils improve efficiency by allowing for the simultaneous printing of different component types in a single process, reducing the need for multiple stencils and print runs.

3. What manufacturing techniques are used to create step stencils?

- Step stencils can be manufactured using chemical etching, laser cutting and welding, and micromachining (micromilling). Each method offers different levels of precision and flexibility.

4. What are the benefits of using micromachining for step stencil production?

- Micromachining offers the highest precision and flexibility, allowing for complex shapes without distortion or burrs. It is also economical for creating stencils with multiple steps.

5. How do step stencils help in managing solder paste volume for mixed-component PCBs?

- Step stencils manage solder paste volume by varying the stencil thickness across different areas. Thicker areas are used for large components requiring more solder, while thinner areas are used for smaller components needing less solder.

Citations:

[1] https://www.npiservices.com/step-up-and-step-down-stencils/

[2] https://www.pcbtok.com/smt-manufacturing-process/

[3] https://www.latechlaser.com/news/future-trends-in-smt-stencil-laser-cutting-tec-78495992.html

[4] https://blueringstencils.com/step-technology/

[5] https://www.elepcb.com/blog/pcb-stencil-smt-assembly/

[6] https://www.pcbway.com/blog/PCB_Manufacturing_Information/Get_to_know_the_Multi_level__Step_Stencil.html

[7] https://blueringstencils.com/wp-content/uploads/2019/01/Step-Technology-SMTAI-2018-Paper-and-Presentation.pdf

[8] https://rushpcb.com/what-are-step-stencils/

[9] https://www.tech-sparks.com/step-stencil/

[10] https://iconnect007.com/article/108107/step-stencil-technologies-and-their-effect-on-the-smt-printing-process/108110/flex

[11] https://www.globalwellpcba.com/how-to-choose-a-smt-stencil/

[12] https://www.pcbelec.com/how-to-use-pcb-stencil.html

[13] https://m.smt11.com/blog/SMT-Field/SMT-Process-Status-and-Future-Development-Trends-2023.html

[14] https://developer.tuya.com/en/docs/iot/SecuritysensorPCBAGuide?id=Kc0rkrscfdfso

[15] https://www.instructables.com/Solder-Using-SMD-Stencil/

[16] https://pcbpit.com/smt-stencil-a-comprehensive-guide/

[17] https://www.becktronic.com/smd-stencils/stepped-stencils/

[18] https://meridian.allenpress.com/ism/article/2017/1/000646/35617/Stencil-Print-solutions-for-Advance-Packaging

[19] https://blueringstencils.com/top-5-smt-industry-trends-for-2019/

[20] https://tecan.co.uk/wp-content/uploads/2023/10/1-an-introduction-to-SMT-and-Stencils-compressed.pdf