Content Menu

● Introduction to SMT Tape and Reel Services

>> Benefits of SMT Tape and Reel Services

● How SMT Tape and Reel Services Work

>> Key Components of SMT Tape and Reel Services

● Challenges and Considerations

● Maximizing Efficiency with SMT Tape and Reel Services

● Advanced Technologies in SMT Tape and Reel Services

>> Impact of Industry 4.0 on SMT Tape and Reel Services

● Case Studies: Success Stories with SMT Tape and Reel Services

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of using SMT tape and reel services?

>> 2. How does SMT tape and reel packaging protect components?

>> 3. What role do reel splicing kits play in maximizing efficiency?

>> 4. Can SMT tape and reel services be customized for specific components?

>> 5. What environmental benefits does SMT tape and reel packaging offer?

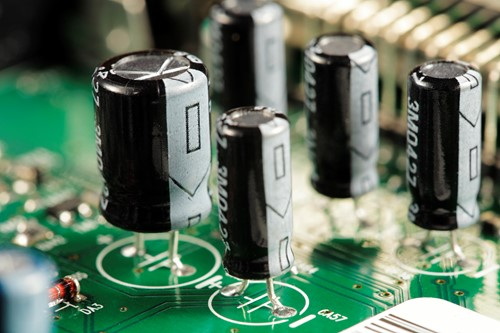

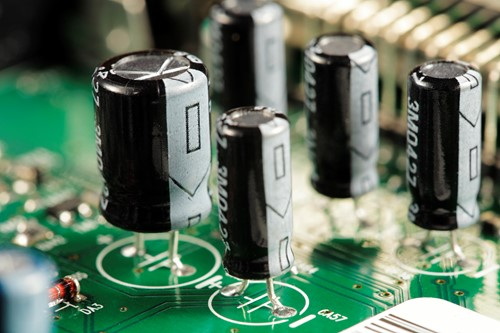

In the fast-paced world of electronics manufacturing, efficiency is key to staying competitive. One of the most effective strategies for enhancing production efficiency is the use of SMT (Surface Mount Technology) tape and reel services. These services involve packaging electronic components in a continuous strip of tape, which is then sealed and wound onto a reel. This format allows for seamless integration into automated assembly processes, significantly boosting productivity while maintaining high-quality standards.

Introduction to SMT Tape and Reel Services

SMT tape and reel services are designed to optimize the production of electronic components by automating the component placement process. This method is particularly beneficial for high-volume production, where minimizing downtime and maximizing machine utilization are crucial for meeting deadlines and maintaining competitiveness.

Benefits of SMT Tape and Reel Services

1. Enhanced Efficiency: By automating the component placement process, manufacturers can achieve faster throughput and longer uninterrupted production runs. This streamlined process eliminates the time-consuming task of manually loading components onto the production line, enabling faster setup and reducing the time required for each production cycle.

2. Reduced Labor Costs: Manual handling of components can lead to errors, delays, and increased waste, all of which impact the bottom line. Automated processes minimize these risks, ensuring consistent quality and reducing the need for manual intervention.

3. Environmental Advantages: The packaging materials used in SMT tape and reel services are often recyclable, reducing waste and minimizing the environmental impact of electronics manufacturing.

4. Improved Inventory Management: The compact and organized nature of SMT tape and reel packaging simplifies inventory management. Components can be easily tracked and stored, reducing the risk of misplacement or damage.

How SMT Tape and Reel Services Work

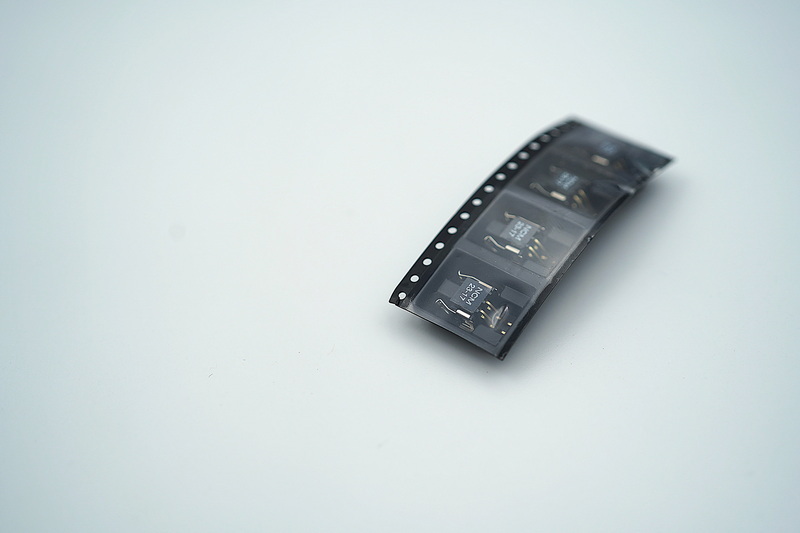

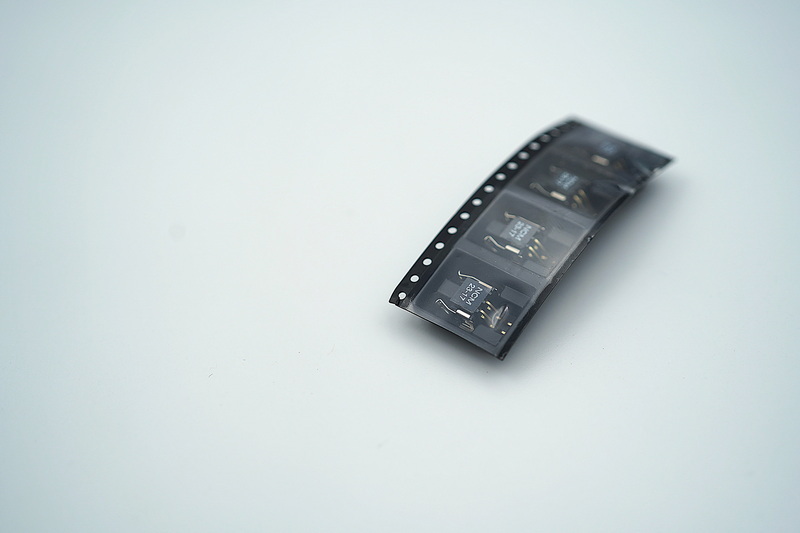

SMT tape and reel services involve placing electronic components into pre-molded cavities on a continuous strip of tape, which is then sealed with a cover tape to protect the components during transportation and storage. The components are wound onto a reel, which can be easily fed into automated assembly equipment, such as pick-and-place machines. This process allows for rapid and precise placement of components onto printed circuit boards (PCBs), significantly reducing manual labor and the risk of errors.

Key Components of SMT Tape and Reel Services

- Carrier Tape: This is the base material that holds the components. It can be made from paper or durable plastic and has pockets that hold components securely in place.

- Cover Tape: This seals the components within the pockets, ensuring they maintain their orientation and are protected from environmental factors.

- Reel: The tape is wound onto a reel, which comes in various sizes to accommodate different component types and quantities.

Challenges and Considerations

While SMT tape and reel services offer numerous benefits, there are challenges to consider:

- Initial Investment: The initial cost of automated equipment can be substantial, and ensuring compatibility with existing machinery is crucial.

- Component Selection: Selecting the right tape and reel specifications for specific components and assembly processes is important to avoid inefficiencies and downtime.

Maximizing Efficiency with SMT Tape and Reel Services

To maximize the benefits of SMT tape and reel services, manufacturers should consider the following strategies:

- Reel Splicing: Using reel splicing kits can dramatically improve reel setup and changeover efficiencies, allowing for continuous production without interruptions.

- Customized Solutions: Working with providers that offer custom tape and reel services can help tailor packaging to specific component needs, enhancing efficiency and reducing waste.

- Training and Support: Ensuring that production staff are well-trained in handling SMT tape and reel systems is essential for maintaining efficiency and minimizing errors.

Advanced Technologies in SMT Tape and Reel Services

The integration of advanced technologies, such as AI and IoT, into SMT tape and reel services is transforming the industry. These technologies enable real-time monitoring of production processes, predictive maintenance, and optimized inventory management. For instance, sensors can detect issues with reel quality or component alignment, allowing for immediate adjustments to maintain production quality.

Impact of Industry 4.0 on SMT Tape and Reel Services

Industry 4.0 technologies are revolutionizing manufacturing by enhancing automation, data exchange, and manufacturing technologies. In the context of SMT tape and reel services, this means:

- Smart Factories: Implementing smart factory concepts allows for seamless integration of SMT tape and reel systems with other production processes, creating a highly efficient and interconnected manufacturing environment.

- Data Analytics: Advanced data analytics tools can analyze production data from SMT tape and reel systems to identify bottlenecks and optimize production workflows.

Case Studies: Success Stories with SMT Tape and Reel Services

Several companies have seen significant improvements in production efficiency by adopting SMT tape and reel services. For example, a leading electronics manufacturer reported a 30% reduction in production time and a 25% decrease in labor costs after implementing automated SMT tape and reel systems. Another company achieved a 20% increase in product quality due to the reduced risk of manual handling errors.

Conclusion

In conclusion, SMT tape and reel services are a powerful tool for enhancing efficiency and reducing production time in electronics manufacturing. By automating component placement, minimizing downtime, and improving inventory management, manufacturers can significantly boost productivity while maintaining high-quality standards. As the electronics industry continues to evolve, the role of SMT tape and reel services will remain vital in optimizing production processes.

Frequently Asked Questions

1. What are the primary benefits of using SMT tape and reel services?

SMT tape and reel services offer enhanced efficiency, reduced labor costs, environmental advantages, and improved inventory management. They automate the component placement process, minimize manual errors, and ensure components are protected during transportation and storage.

2. How does SMT tape and reel packaging protect components?

Components are placed in pre-molded cavities on the carrier tape and sealed with cover tape. This protects them from damage during transportation and storage, ensuring they arrive at the assembly line in pristine condition.

3. What role do reel splicing kits play in maximizing efficiency?

Reel splicing kits allow for the continuous joining of component reels, preventing production stoppages and reducing downtime. This results in significant time savings and cost reductions associated with uninterrupted assembly processes.

4. Can SMT tape and reel services be customized for specific components?

Yes, many providers offer custom tape and reel services to accommodate unique component requirements. This can include custom carrier tape sizes and reel diameters to ensure optimal efficiency and reduce waste.

5. What environmental benefits does SMT tape and reel packaging offer?

SMT tape and reel packaging reduces waste and minimizes the environmental impact of electronics manufacturing by using recyclable materials and optimizing component usage.