Content Menu

● Introduction to SMT Tape and Reel

● Benefits of SMT Tape and Reel

>> Enhanced Efficiency

>> Reduced Labor Costs

>> Improved Quality and Reliability

>> Environmental Benefits

● How SMT Tape and Reel Saves Time

>> Streamlined Component Handling

>> Reduced Downtime

>> Efficient Inventory Management

● SMT Splicing Tapes: Enhancing Efficiency Further

>> Benefits of SMT Splicing Tapes

>> Techniques of SMD Splicing

>> Minimizing Potential Drawbacks

● Evolution and Applications of Tape and Reel Packaging

>> Evolution

>> Applications Beyond Electronics

>> Custom Solutions

● Additional Benefits of SMT Tape and Reel

>> Enhanced Precision

>> Cost-Effective Production

>> Industry Expansion

● Future Developments and Innovations

● Challenges and Considerations

● Conclusion

● Frequently Asked Questions

>> 1. What is SMT Tape and Reel Packaging?

>> 2. How Does SMT Tape and Reel Save Time in Manufacturing?

>> 3. What Are the Environmental Benefits of Using SMT Tape and Reel?

>> 4. How Do SMT Splicing Tapes Enhance Efficiency?

>> 5. What Are the Key Considerations for Implementing SMT Tape and Reel?

In the fast-paced world of electronics manufacturing, efficiency and precision are paramount. One of the key strategies for achieving these goals is through the use of SMT (Surface Mount Technology) tape and reel packaging. This method has revolutionized the way electronic components are handled and assembled, significantly reducing production time and enhancing overall manufacturing efficiency. In this article, we will delve into the specifics of how SMT tape and reel can save time in electronics manufacturing.

Introduction to SMT Tape and Reel

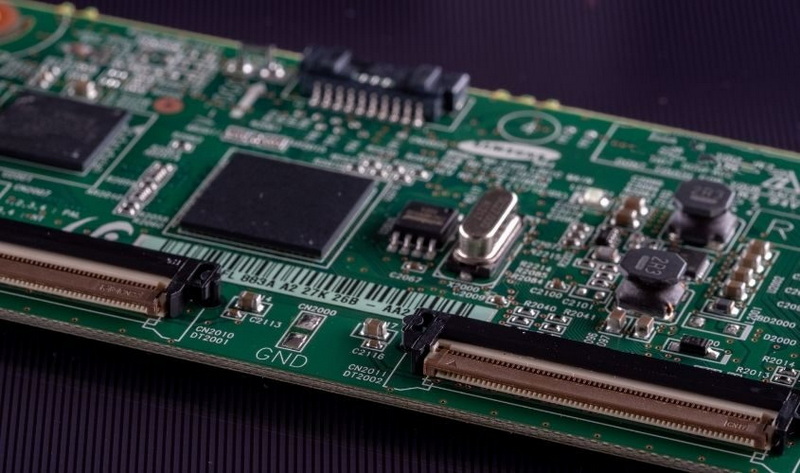

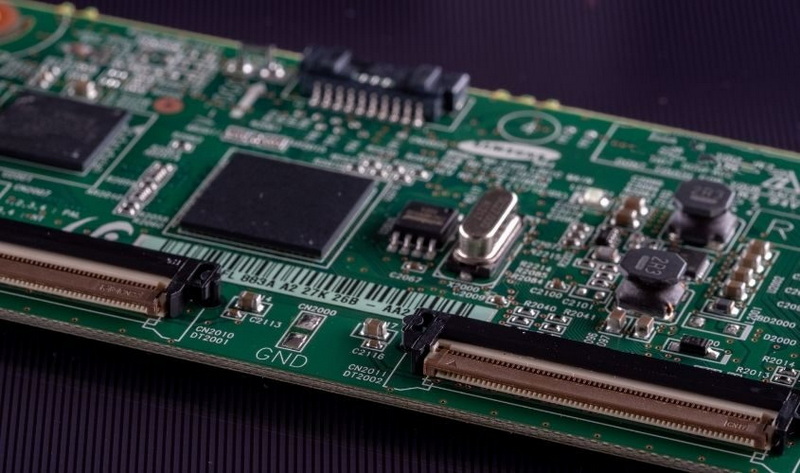

SMT tape and reel packaging involves placing electronic components, such as resistors, capacitors, and integrated circuits, into pre-molded cavities on a continuous strip of tape. This tape is then sealed with a cover tape to protect the components during transportation and storage. The components are wound onto a reel, which can be easily fed into automated assembly equipment, such as pick-and-place machines. This process allows for rapid and precise placement of components onto printed circuit boards (PCBs), significantly reducing manual labor and the risk of errors.

Benefits of SMT Tape and Reel

Enhanced Efficiency

One of the primary benefits of using SMT tape and reel is the enhanced efficiency it brings to the production line. By automating the component placement process, manufacturers can achieve faster throughput and longer uninterrupted production runs. This is particularly beneficial for high-volume production, where minimizing downtime is crucial for meeting deadlines and maintaining competitiveness.

Reduced Labor Costs

Transitioning from manual to automated assembly processes with SMT tape and reel significantly reduces labor costs. Manual handling of components can lead to errors, delays, and increased waste, all of which impact the bottom line. Automated processes minimize these risks, ensuring consistent quality and reducing the need for manual intervention.

Improved Quality and Reliability

SMT tape and reel packaging protects components from damage during transportation and storage, ensuring they arrive at the assembly line in pristine condition. This protection, combined with the precision of automated placement, results in higher quality products with fewer defects.

Environmental Benefits

The use of SMT tape and reel also offers environmental advantages. The packaging materials are often recyclable, reducing waste and minimizing the environmental impact of electronics manufacturing. Additionally, the efficient use of materials reduces the overall carbon footprint of production processes.

How SMT Tape and Reel Saves Time

Streamlined Component Handling

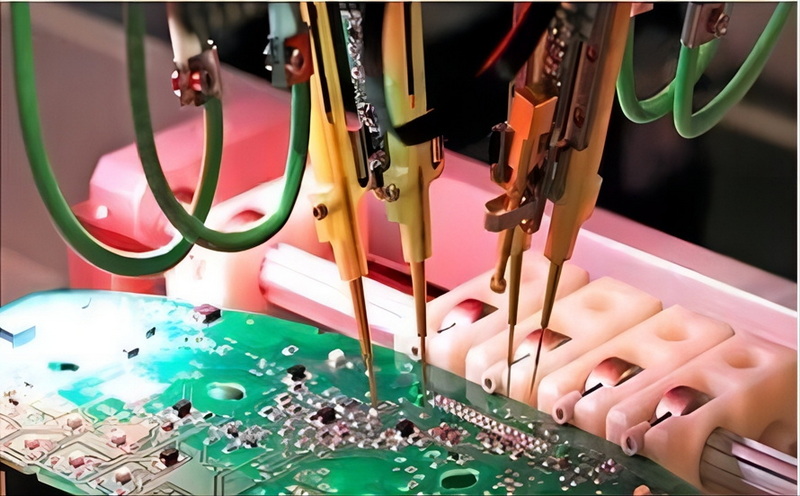

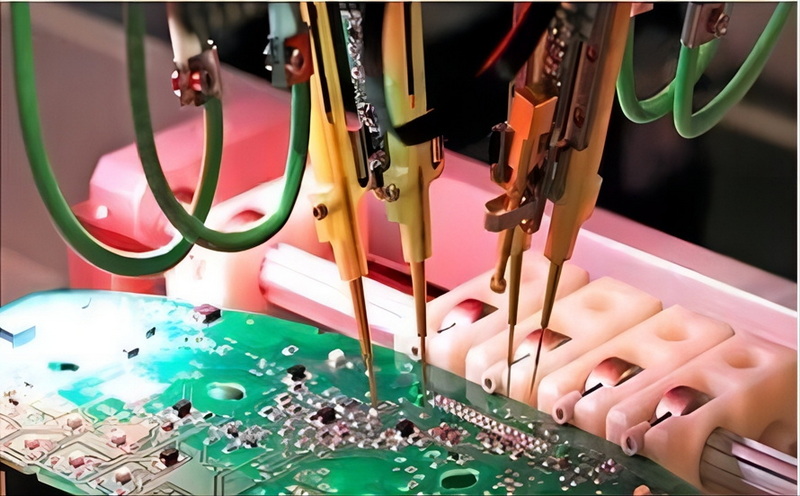

SMT tape and reel allows components to be fed directly into automated assembly equipment without manual intervention. This streamlined process eliminates the time-consuming task of manually loading components onto the production line, enabling faster setup and reducing the time required for each production cycle.

Reduced Downtime

Traditional component handling methods often involve frequent line stoppages for reloading. In contrast, SMT tape and reel enables longer, uninterrupted production runs. With a continuous supply of components, assembly lines can operate at full capacity, minimizing downtime and maximizing productivity.

Efficient Inventory Management

The compact and organized nature of SMT tape and reel packaging simplifies inventory management. Components can be easily tracked and stored, reducing the risk of misplacement or damage. This efficient management ensures that production can continue without interruptions due to component shortages.

SMT Splicing Tapes: Enhancing Efficiency Further

In addition to SMT tape and reel, SMT splicing tapes play a crucial role in maintaining continuous production. These tapes are used to join the ends of component reels, allowing for uninterrupted assembly processes. By eliminating the need to stop production to load new reels, manufacturers can save significant time and reduce costs associated with downtime.

Benefits of SMT Splicing Tapes

- Time Savings: By joining component reels, manufacturers can prevent production stoppages, saving time and reducing labor costs.

- Increased Efficiency: Continuous production without interruptions boosts overall efficiency and productivity.

- Ease of Use: SMT splicing tapes are designed to be user-friendly and compatible with standard SMT pick-and-place feeders.

Techniques of SMD Splicing

SMD splicing involves joining two Surface Mount Device (SMD) component tapes together. This can be done manually or automatically:

- Manual Splicing: This traditional method requires operators to manually cut the carrier tape and join the ends using an SMD splice connector. It demands skill and precision.

- Automatic Splicing: Modern facilities use automatic SMD splice machines to automate the process, increasing accuracy and efficiency.

Minimizing Potential Drawbacks

While SMT splicing tapes offer numerous benefits, there are potential drawbacks to consider:

- Quality Assurance: Investing in high-quality SMT splice tapes reduces the risk of blockages and misfeeds, ensuring smooth production.

- Best Practices: Following best practices during splicing minimizes issues. Proper training and adherence to guidelines are crucial.

Evolution and Applications of Tape and Reel Packaging

Evolution

Tape and reel packaging has evolved alongside surface mount technology (SMT) to enable efficient component placement on both sides of printed circuit boards. This method allows for higher component density and longer production runs compared to traditional packaging methods like trays.

Applications Beyond Electronics

The efficiency and precision of tape and reel packaging have expanded its use beyond electronics. Industries such as medical devices and power tools now utilize this method for automating the placement of small components, including heat sinks and sensors.

Custom Solutions

For unique components, custom tape and reel solutions are designed to ensure compatibility with automated assembly equipment. This involves creating a flat pickup surface on the component, sometimes using materials like Kapton tape to facilitate accurate placement.

Additional Benefits of SMT Tape and Reel

Enhanced Precision

The precision of SMT tape and reel packaging ensures that components are consistently oriented and placed accurately on PCBs. This is particularly important for components with polarity or specific alignment requirements, as it minimizes errors and improves product reliability.

Cost-Effective Production

By minimizing material waste and ensuring efficient component usage, SMT tape and reel contributes to cost-effective production. Unlike bulk packaging methods, where components may be loosely packed or exposed, tape and reel packaging ensures that every component is protected and used effectively.

Industry Expansion

The efficiency and precision of tape and reel packaging have led to its adoption in industries beyond electronics, such as medical devices and power tools. This expansion highlights the versatility of the technology and its potential for automating small component placement across diverse sectors.

Future Developments and Innovations

As technology advances, we can expect further innovations in SMT tape and reel packaging. These may include enhanced automation capabilities, improved material sustainability, and expanded compatibility with emerging component types. Such developments will continue to enhance efficiency and reduce production times in electronics manufacturing.

Challenges and Considerations

While SMT tape and reel offers numerous benefits, there are challenges to consider:

- Initial Investment: The initial cost of automated equipment can be substantial, and ensuring compatibility with existing machinery is crucial.

- Component Selection: Selecting the right tape and reel specifications for specific components and assembly processes is important to avoid inefficiencies and downtime.

Conclusion

In conclusion, SMT tape and reel packaging is a powerful tool for enhancing efficiency and reducing production time in electronics manufacturing. By automating component placement, minimizing downtime, and improving inventory management, manufacturers can significantly boost productivity while maintaining high-quality standards. As the electronics industry continues to evolve, the role of SMT tape and reel will remain vital in optimizing production processes.

Frequently Asked Questions

1. What is SMT Tape and Reel Packaging?

SMT tape and reel packaging involves placing electronic components into pre-molded cavities on a continuous strip of tape, which is then sealed and wound onto a reel. This format allows for easy integration into automated assembly processes, enhancing efficiency and precision.

2. How Does SMT Tape and Reel Save Time in Manufacturing?

SMT tape and reel saves time by automating component placement, reducing manual labor, and minimizing downtime. It enables longer uninterrupted production runs and streamlines inventory management, leading to faster setup times and increased productivity.

3. What Are the Environmental Benefits of Using SMT Tape and Reel?

The use of SMT tape and reel offers environmental benefits by reducing waste and minimizing the carbon footprint of production processes. The materials used are often recyclable, contributing to sustainability efforts in electronics manufacturing.

4. How Do SMT Splicing Tapes Enhance Efficiency?

SMT splicing tapes enhance efficiency by allowing the continuous joining of component reels, preventing production stoppages and reducing downtime. This results in significant time savings and cost reductions associated with uninterrupted assembly processes.

5. What Are the Key Considerations for Implementing SMT Tape and Reel?

Key considerations include ensuring compatibility with existing machinery, selecting appropriate tape and reel specifications, and addressing the initial investment in automated equipment. Proper planning and implementation are crucial to maximize the benefits of SMT tape and reel packaging.