Content Menu

● Understanding SMT Stencil Printers and Their Role

>> What Is an SMT Stencil Printer?

>> The Function of the SMT Stencil

>> Types of SMT Stencils

● How SMT Stencil Printers Enhance Solder Paste Accuracy

>> Precise Alignment Systems

>> Controlled Solder Paste Application

>> Automation and Repeatability

>> Stencil Design and Material Quality

● Key Factors Influencing SMT Stencil Printing Accuracy

>> Stencil Aperture Size and Area Ratio

>> Solder Paste Properties

>> Environmental Conditions

>> PCB and Stencil Surface Cleanliness

● Best Practices for Optimizing SMT Stencil Printing

● Emerging Technologies in SMT Stencil Printing

● Conclusion

● FAQ

>> 1. What is an SMT stencil screen printer used for?

>> 2. How does stencil thickness affect solder paste accuracy?

>> 3. What role does the vision alignment system play in SMT stencil printing?

>> 4. How often should SMT stencils be cleaned?

>> 5. Can the same stencil be used for different solder paste types?

Surface Mount Technology (SMT) stencil printers, also known as SMT stencil screen printers, play a pivotal role in modern electronics manufacturing by ensuring precise and consistent solder paste application on printed circuit boards (PCBs). Accurate solder paste deposition is critical for reliable component placement and solder joint quality, directly impacting the performance and durability of electronic devices. This article explores how SMT stencil printers improve solder paste accuracy, the technology behind them, key factors influencing printing quality, and best practices to optimize the process.

Understanding SMT Stencil Printers and Their Role

What Is an SMT Stencil Printer?

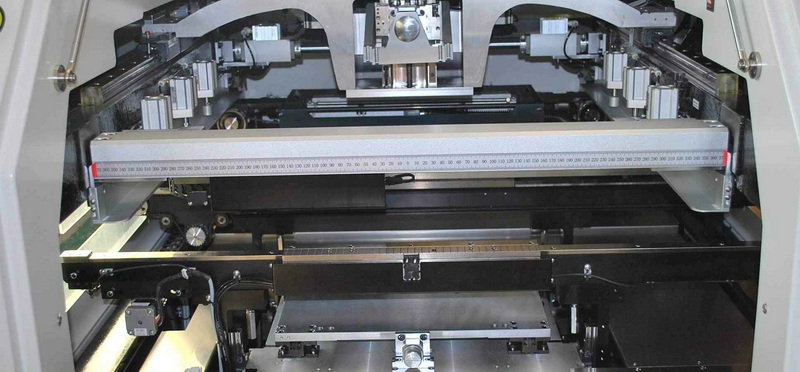

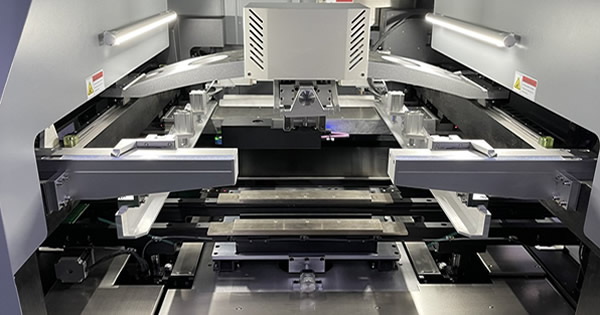

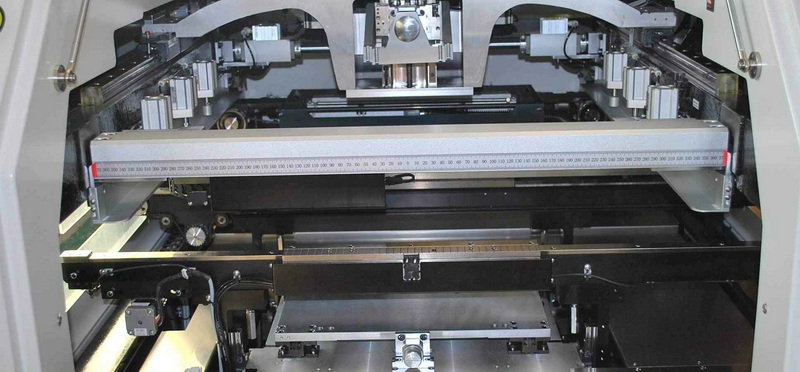

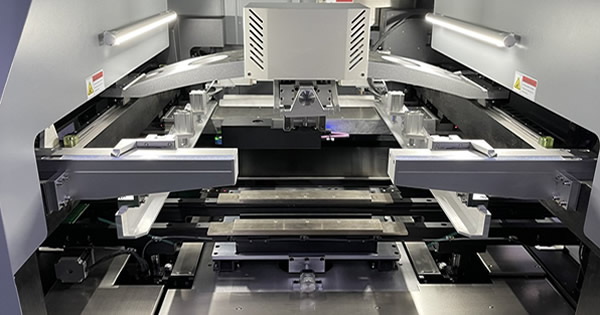

An SMT stencil printer is a specialized machine used in the SMT assembly process to apply solder paste onto PCB pads. It operates by aligning a metal stencil-usually made of stainless steel-with the PCB and then spreading solder paste across the stencil openings using a squeegee. The solder paste passes through the precisely cut apertures in the stencil and deposits onto the PCB pads, readying the board for component placement and soldering.

The Function of the SMT Stencil

The SMT stencil serves as a template that dictates the exact location and volume of solder paste applied. The stencil contains fine apertures that match the footprint of the PCB pads where surface-mount components will be placed. The stencil thickness and aperture size are carefully designed to control the amount of solder paste deposited, which is crucial for avoiding defects such as solder bridging or insufficient solder joints.

Types of SMT Stencils

There are several types of SMT stencils, including:

- Laser-cut stencils: These are the most common and are made by laser cutting apertures into stainless steel sheets. They offer high precision and repeatability.

- Electroformed stencils: Made by electroplating nickel, these stencils provide extremely smooth aperture walls and are ideal for very fine-pitch components.

- Step stencils: These have varying thicknesses in different areas, allowing customized paste volume for different component sizes on the same PCB.

- Flexible stencils: Made from thin metal or polymer, useful for curved or flexible PCBs.

How SMT Stencil Printers Enhance Solder Paste Accuracy

Precise Alignment Systems

Modern SMT stencil printers use advanced vision alignment systems with high-resolution cameras to ensure the stencil apertures align perfectly with the PCB pads. This alignment accuracy can reach ±0.01mm, significantly reducing misalignment risks that cause solder paste offset and defects. Automated fiducial recognition and image processing enable real-time corrections during the printing process, enhancing repeatability and precision.

These vision systems often employ multiple cameras to capture fiducial marks on both the stencil and PCB, calculating any positional offsets or rotations. The printer's control software then adjusts the stencil position accordingly before printing. This level of precision is especially important for high-density PCBs with fine-pitch components, where even slight misalignment can cause solder bridging or insufficient paste deposition.

Controlled Solder Paste Application

SMT stencil printers regulate the application of solder paste through controlled squeegee pressure, speed, and angle. Proper adjustment of these parameters ensures uniform paste thickness and prevents issues like paste smearing or insufficient filling of stencil apertures.

- Squeegee pressure: Too high pressure can cause paste to squeeze under the stencil or smear, while too low pressure results in incomplete aperture filling.

- Printing speed: Printing too fast can lead to uneven paste deposition; too slow reduces throughput.

- Separation speed: The speed at which the stencil separates from the PCB affects paste release; proper speed prevents smudging or paste stringing.

Typical squeegee pressure settings range between 0.2kg/cm² and 0.5kg/cm², with printing speeds optimized between 20mm/s and 50mm/s to balance quality and throughput. Many modern printers allow programmable control of these parameters for different PCB designs and paste types.

Automation and Repeatability

Automated SMT stencil printers reduce human error by standardizing the paste printing process. Features such as automatic stencil cleaning, calibration, and paste thickness monitoring contribute to consistent solder paste deposition across large production volumes. This consistency is vital for maintaining high yields and reducing rework costs.

For example, some printers include integrated paste inspection systems that measure the volume and shape of deposited paste in real-time, alerting operators to deviations from set parameters. Automatic cleaning cycles prevent paste buildup on stencil apertures, which can otherwise cause clogging and inconsistent prints.

Stencil Design and Material Quality

The stencil itself is critical to solder paste accuracy. High-quality stencils are fabricated with precise aperture sizes, smooth walls, and appropriate thickness tailored to the PCB design and component types. Step stencils, which have varying thicknesses in different areas, allow optimized paste volumes for components with different soldering requirements on the same board.

Material choice affects stencil durability and print quality. Stainless steel is the industry standard due to its strength and resistance to wear. Electroformed nickel stencils offer superior aperture wall smoothness, improving paste release and print consistency, especially for ultra-fine pitch components.

Key Factors Influencing SMT Stencil Printing Accuracy

Stencil Aperture Size and Area Ratio

The aperture size typically ranges between 80% to 90% of the PCB pad size to ensure adequate solder coverage without overflow. The area ratio, defined as the aperture opening area divided by the aperture wall area, should ideally be 0.66 or higher to facilitate efficient paste release from the stencil.

A low area ratio can cause incomplete paste release, leading to insufficient solder on the pads. Designers must carefully balance aperture size and stencil thickness to maintain an optimal area ratio, especially for fine-pitch components where apertures are very small.

Solder Paste Properties

The solder paste's viscosity, particle size, and metal content affect its printability. Paste must be stored properly (2℃–10℃) and brought to room temperature before use, with thorough stirring to maintain consistent rheological properties. Using the correct solder paste type for the stencil and PCB design is essential for optimal printing results.

Paste viscosity influences how well it fills stencil apertures and releases onto the PCB. High viscosity pastes may clog apertures or cause smearing, while low viscosity pastes can slump or spread excessively. Proper paste storage, handling, and mixing are crucial to maintaining consistent printing performance.

Environmental Conditions

Temperature and humidity influence solder paste behavior. High temperatures reduce viscosity, while improper humidity can cause paste drying or moisture absorption, leading to printing defects such as pinholes or solder balling. Maintaining a controlled environment is necessary for stable printing quality.

Typical recommended conditions are 20℃–25℃ with 40%–60% relative humidity. Many SMT assembly lines are equipped with environmental controls to maintain these parameters, ensuring consistent paste characteristics and print quality.

PCB and Stencil Surface Cleanliness

Foreign particles or residues on the PCB or stencil can interfere with paste transfer and alignment. Regular cleaning of the stencil every 4 hours and pre-print cleaning of PCBs with air guns or electrostatic brushes prevent contamination and ensure smooth printing cycles.

Contamination can cause paste smearing, bridging, or insufficient deposition. Additionally, oxidation on stencil surfaces reduces paste release efficiency. Using anti-oxidation coatings or treatments on stencils can improve performance and longevity.

Best Practices for Optimizing SMT Stencil Printing

- Regular Stencil Maintenance: Clean stencils frequently using ultrasonic or automated cleaning systems to prevent aperture clogging and maintain print quality. Avoid abrasive cleaning methods that can damage stencil apertures.

- Accurate Parameter Setup: Fine-tune squeegee pressure, printing speed, and separation speed to suit the solder paste and PCB design. Conduct test prints and inspections before full production runs.

- Use of Advanced Equipment: Invest in high-precision SMT stencil printers with automated alignment, cleaning, and inspection features to improve efficiency and reduce defects.

- Stencil Inspection and Replacement: Periodically inspect stencils for wear or damage and replace them as needed to maintain printing accuracy. Aperture deformation or burrs can cause paste defects.

- Environmental Control: Maintain stable temperature and humidity in the production area to ensure consistent solder paste performance.

- Training and Process Documentation: Ensure operators are well-trained in stencil printer operation and maintenance. Document printing parameters and procedures for repeatability.

- Implement Paste Inspection Systems: Use post-print paste inspection (SPI) to verify solder paste volume and placement, enabling early defect detection and process correction.

Emerging Technologies in SMT Stencil Printing

The SMT stencil printing process continues to evolve with innovations aimed at improving solder paste accuracy and production efficiency:

- Laser Direct Imaging (LDI): Some manufacturers are exploring LDI to create solder paste deposits directly on PCBs without stencils, potentially eliminating stencil-related issues.

- Nano-coatings on Stencils: Applying hydrophobic or anti-adhesive coatings on stencil surfaces improves paste release and reduces cleaning frequency.

- Artificial Intelligence (AI) and Machine Learning: AI algorithms analyze printing data to optimize parameters dynamically and predict maintenance needs.

- 3D Stencil Printing: Advanced 3D printing techniques enable complex stencil geometries and customized aperture shapes for challenging PCB designs.

These technologies promise to further enhance solder paste accuracy, reduce defects, and increase throughput in SMT assembly lines.

Conclusion

SMT stencil printers significantly improve solder paste accuracy by combining precise stencil design, advanced alignment systems, controlled paste application, and automated processes. These factors collectively enhance solder joint quality, reduce defects, and increase production efficiency. By adhering to best practices in stencil maintenance, parameter optimization, and environmental control, manufacturers can achieve consistent, high-quality PCB assemblies essential for reliable electronic products.

Moreover, ongoing advancements in stencil materials, printing technology, and process monitoring continue to push the boundaries of solder paste accuracy, enabling the production of increasingly complex and miniaturized electronic devices.

FAQ

1. What is an SMT stencil screen printer used for?

An SMT stencil screen printer is used to apply solder paste accurately onto PCB pads by aligning a metal stencil with the board and spreading paste through stencil apertures, preparing the PCB for component placement.

2. How does stencil thickness affect solder paste accuracy?

Stencil thickness controls the volume of solder paste deposited; thinner stencils are used for fine-pitch components to prevent excess paste, while thicker stencils deposit more paste for larger pads.

3. What role does the vision alignment system play in SMT stencil printing?

Vision alignment systems use cameras and image processing to precisely align the stencil with PCB pads, reducing misalignment and improving solder paste placement accuracy.

4. How often should SMT stencils be cleaned?

Stencils should be cleaned every 4 hours during production to remove solder paste residues and prevent aperture clogging, ensuring consistent print quality.

5. Can the same stencil be used for different solder paste types?

It is generally recommended to use separate stencils for different solder paste types to avoid cross-contamination and maintain printing performance.