Content Menu

● Understanding SMT Production Equipment

● The Role of Automation in Cost Reduction

>> Increased Production Speed

>> Minimized Labor Costs

● Enhancing Efficiency Through Advanced Technology

>> Precision and Accuracy

>> Automated Optical Inspection

● Reducing Material Waste

>> Efficient Material Usage

>> Inventory Management

● Energy Efficiency

● Long-Term Investment Returns

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How does automation impact labor costs in SMT?

>> 3. What are some key pieces of equipment used in an SMT line?

>> 4. How does SMT help in reducing material waste?

>> 5. Is investing in SMT equipment worth it?

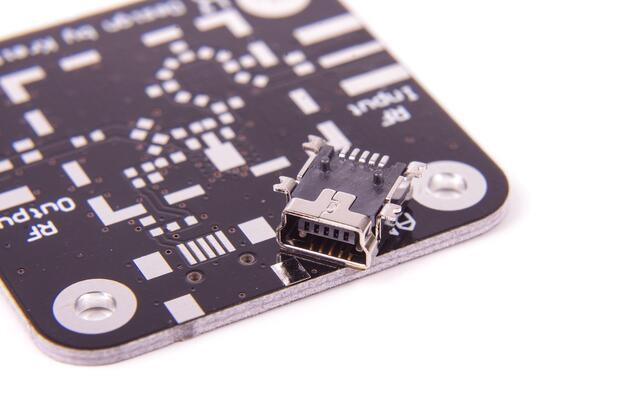

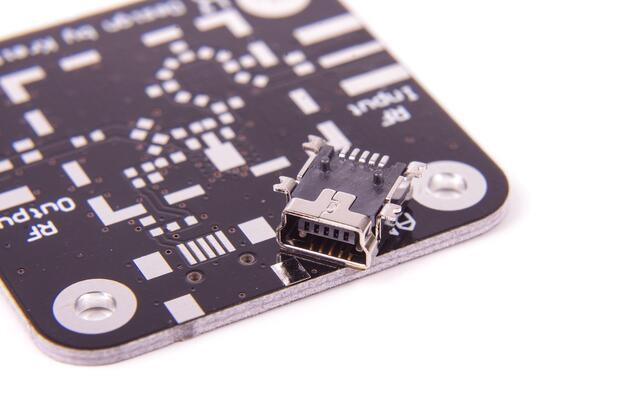

Surface Mount Technology (SMT) has fundamentally transformed the electronics manufacturing landscape by enabling efficient assembly of electronic components directly onto the surface of printed circuit boards (PCBs). This method not only enhances production speed but also significantly reduces costs associated with manufacturing. In this article, we will explore how SMT production equipment can effectively reduce production costs, focusing on various aspects such as automation, efficiency, and advanced technology.

Understanding SMT Production Equipment

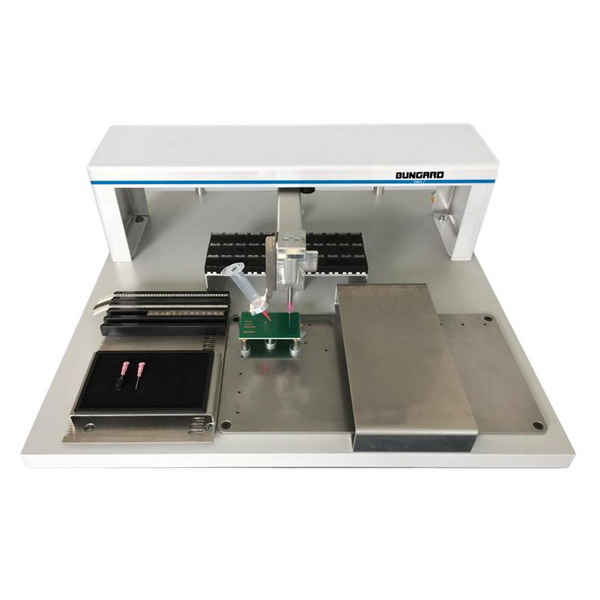

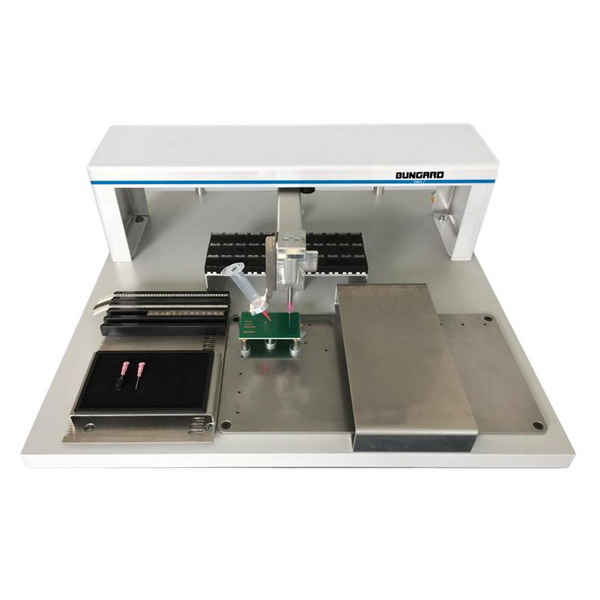

SMT production equipment includes a range of machines that automate the assembly process. Key components of an SMT line typically include:

- Stencil Printers: Used for applying solder paste onto PCBs.

- Pick-and-Place Machines: Responsible for placing components onto the boards.

- Reflow Ovens: Melt solder paste to create electrical connections.

- Inspection Systems: Ensure quality control by checking for defects.

Each piece of equipment plays a crucial role in enhancing production efficiency and minimizing costs.

The Role of Automation in Cost Reduction

Increased Production Speed

One of the primary advantages of SMT production equipment is automation. Automated machines can significantly increase production speed, allowing manufacturers to produce more units in less time. For instance, modern pick-and-place machines can place up to 80,000 components per hour, vastly outpacing manual assembly processes. This increase in speed translates directly into reduced labor costs and higher output.

Minimized Labor Costs

With the implementation of automated systems, manufacturers can reduce their reliance on manual labor. This not only cuts down on labor costs but also minimizes human error, which can lead to costly rework and defects. By automating repetitive tasks, companies can allocate their workforce to more skilled positions that require human oversight and decision-making.

Enhancing Efficiency Through Advanced Technology

Precision and Accuracy

Advanced SMT equipment is designed to operate with high precision. Automated optical inspection (AOI) systems are integrated into the production line to catch defects early in the process. By identifying issues such as misaligned components or solder defects before they escalate, manufacturers can avoid costly rework later on.

Automated Optical Inspection

SMT production lines are designed to optimize workflow by minimizing setup times and streamlining processes. For example, modern stencil printers are equipped with features that allow for quick adjustments between different PCB designs. This flexibility enables manufacturers to respond swiftly to market demands without incurring significant downtime.

Reducing Material Waste

Efficient Material Usage

SMT technology allows for better utilization of materials compared to traditional methods. The precision of automated machines reduces excess solder paste application and minimizes component waste. Moreover, smaller surface mount devices (SMDs) require less space on PCBs, enabling manufacturers to create more compact designs that use fewer materials overall.

Inventory Management

By adopting just-in-time (JIT) inventory practices alongside SMT production equipment, manufacturers can reduce holding costs associated with excess inventory. JIT allows companies to order materials as needed, reducing waste and ensuring that capital is not tied up in unused stock.

Energy Efficiency

Modern SMT production equipment is designed with energy efficiency in mind. For instance, reflow ovens with multiple temperature zones can optimize energy usage by only heating specific areas as needed during the soldering process. This not only reduces operational costs but also aligns with sustainability goals by lowering the carbon footprint of manufacturing operations.

Long-Term Investment Returns

While the initial investment in SMT production equipment can be substantial—ranging from $100,000 to $500,000—the long-term savings often outweigh these costs. Companies that invest in high-quality SMT machines typically see a return on investment through reduced labor costs, lower material waste, and increased throughput over time.

Conclusion

In conclusion, SMT production equipment plays a pivotal role in reducing production costs within the electronics manufacturing industry. By leveraging automation, enhancing efficiency through advanced technology, minimizing material waste, and improving energy consumption, manufacturers can significantly lower their operational expenses while maintaining high-quality output. As the industry continues to evolve, investing in state-of-the-art SMT technology will be crucial for companies aiming to remain competitive in a cost-sensitive market.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used in electronics manufacturing where components are mounted directly onto the surface of PCBs rather than being inserted through holes.

2. How does automation impact labor costs in SMT?

Automation reduces reliance on manual labor by performing repetitive tasks quickly and accurately, leading to lower labor costs and minimized human error.

3. What are some key pieces of equipment used in an SMT line?

Key pieces of equipment include stencil printers for solder paste application, pick-and-place machines for component placement, reflow ovens for soldering connections, and inspection systems for quality control.

4. How does SMT help in reducing material waste?

SMT allows for precise placement of components and controlled application of solder paste, which minimizes excess material usage and reduces waste during the manufacturing process.

5. Is investing in SMT equipment worth it?

Yes, while initial investments may be high, the long-term savings from reduced labor costs, lower material waste, and increased production efficiency often justify the expenditure.