Content Menu

● Understanding SMT Technology

● Key Components of an SMT Line

● Benefits of Using SMT Line Machines

>> Increased Production Speed

>> Higher Component Density

>> Reduced Manufacturing Costs

>> Improved Product Quality

>> Enhanced Flexibility and Scalability

● Strategies for Optimizing SMT Line Efficiency

● Challenges Faced by SMT Lines

>> Initial Investment Costs

>> Complexity of Equipment

>> Supply Chain Dependencies

● Future Trends in SMT Technology

>> Industry 4.0 Integration

>> Miniaturization of Components

>> Increased Automation

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How does an SMT line improve production speed?

>> 3. What are the main components of an SMT line?

>> 4. How does using SMT reduce manufacturing costs?

>> 5. What strategies can be implemented to optimize SMT line efficiency?

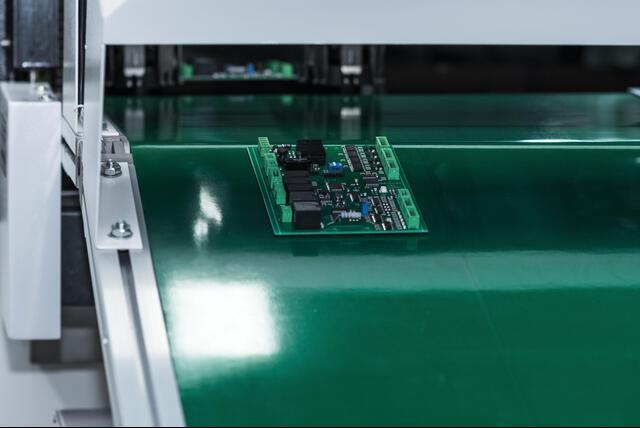

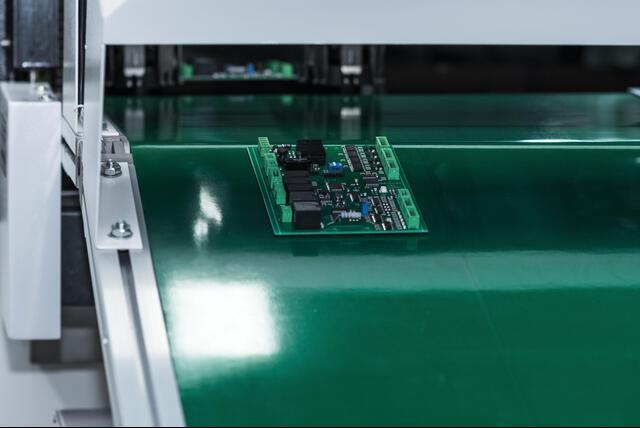

In the fast-paced world of electronics manufacturing, efficiency is paramount. One of the most significant advancements in this field is the adoption of Surface Mount Technology (SMT) lines. These lines utilize specialized machines to automate the assembly of printed circuit boards (PCBs), leading to substantial improvements in manufacturing efficiency. This article explores how SMT line machines enhance production processes, reduce costs, and improve product quality.

Understanding SMT Technology

Surface Mount Technology (SMT) involves mounting electronic components directly onto the surface of PCBs. This method contrasts with traditional through-hole technology, which requires drilling holes for component leads. SMT allows for higher component density, smaller board sizes, and faster production cycles. The automation inherent in SMT lines significantly reduces labor costs and minimizes human error, making it an attractive option for manufacturers.

Key Components of an SMT Line

An SMT line consists of several critical machines that work together to streamline the PCB assembly process:

- SMT Loader: Automatically feeds PCBs into the production line.

- Solder Paste Printer: Applies solder paste to designated areas on the PCB where components will be placed.

- Pick and Place Machine: Accurately positions surface mount devices (SMDs) onto the PCB.

- Reflow Oven: Melts the solder paste to create electrical connections between components and the PCB.

- Automated Optical Inspection (AOI): Checks for defects or misalignments after soldering.

Each component plays a vital role in ensuring that the manufacturing process is efficient and produces high-quality products.

Benefits of Using SMT Line Machines

Increased Production Speed

SMT line machines can significantly increase production speed compared to manual assembly methods. For instance, pick and place machines can place thousands of components per hour, drastically reducing assembly times. This efficiency allows manufacturers to meet tight deadlines and respond quickly to market demands.

Higher Component Density

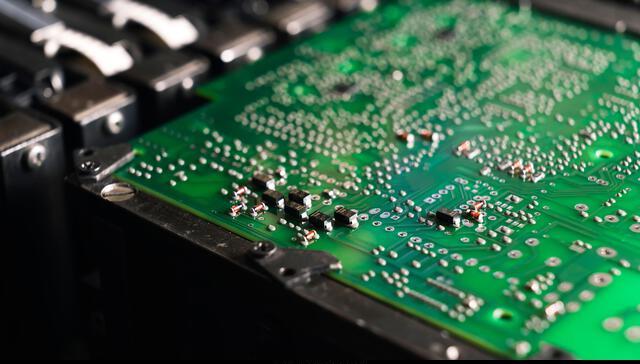

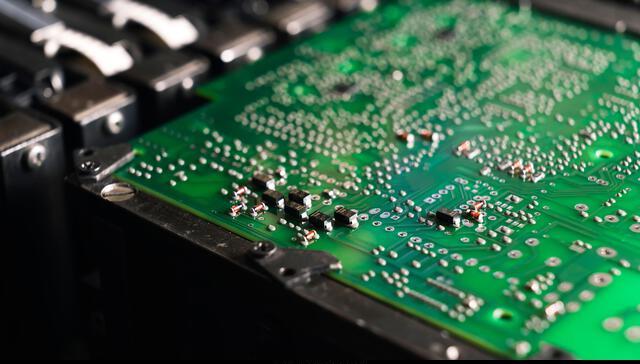

SMT enables a higher component density on PCBs since components are mounted directly on the surface without requiring holes. This capability allows for more compact designs, which is essential in modern electronics where space is often limited. Higher density also contributes to improved performance by reducing signal paths.

Reduced Manufacturing Costs

The automation provided by SMT lines leads to lower labor costs as fewer workers are needed for assembly tasks. Additionally, the reduced need for manual handling minimizes material waste and errors, further decreasing overall production costs. The streamlined process also shortens cycle times, allowing manufacturers to produce more units in less time.

Improved Product Quality

Automated processes in SMT lines enhance product quality by minimizing human error. Machines consistently apply solder paste and position components accurately, resulting in fewer defects. The integration of AOI systems ensures that any issues are detected early in the production process, allowing for quick corrections before products move further down the line.

Enhanced Flexibility and Scalability

Modern SMT lines can be easily adjusted to accommodate different product types or changes in demand. This flexibility allows manufacturers to scale their operations up or down without significant downtime or reconfiguration costs. The ability to switch between different product runs quickly is a crucial advantage in today's fast-moving market.

Strategies for Optimizing SMT Line Efficiency

To maximize the benefits of SMT line machines, manufacturers can implement several strategies:

- Load Balancing: Distributing workloads evenly across machines can prevent bottlenecks and ensure that all parts of the line operate efficiently.

- Regular Maintenance: Keeping machines well-maintained reduces downtime caused by equipment failures and ensures consistent performance.

- Operator Training: Well-trained operators can better manage equipment and troubleshoot issues as they arise, contributing to smoother operations.

- Data Analytics: Utilizing data collected from machines can help identify inefficiencies and areas for improvement within the production process.

- Lean Manufacturing Principles: Implementing lean practices can help minimize waste and optimize workflows throughout the SMT line.

Challenges Faced by SMT Lines

While there are numerous benefits to using SMT line machines, manufacturers may also encounter challenges:

Initial Investment Costs

The initial investment required to set up an SMT line can be substantial. High-quality machinery and equipment are necessary for effective operation, which may deter some manufacturers from transitioning from traditional methods. However, it is essential to consider this as a long-term investment that will yield significant returns through increased efficiency and reduced operational costs over time.

Complexity of Equipment

The complexity of SMT machinery requires skilled operators who understand how to manage and maintain these systems effectively. Manufacturers must invest in training programs to ensure their workforce is equipped with the necessary skills. Failure to do so may lead to inefficient operations or increased downtime due to improper handling or maintenance issues.

Supply Chain Dependencies

SMT lines rely heavily on a consistent supply chain for components and materials. Any disruption in this supply chain can lead to delays in production schedules. Manufacturers must establish strong relationships with suppliers and consider diversifying their sources to mitigate risks associated with supply chain disruptions.

Future Trends in SMT Technology

As technology continues to evolve, several trends are emerging within SMT manufacturing that could further enhance efficiency:

Industry 4.0 Integration

The integration of Industry 4.0 principles into SMT manufacturing involves utilizing IoT (Internet of Things) devices, big data analytics, and artificial intelligence (AI) systems. These technologies enable real-time monitoring of production processes, predictive maintenance, and data-driven decision-making that can optimize efficiency even further.

Miniaturization of Components

As electronic devices become smaller and more complex, there is a growing demand for miniaturized components that require advanced SMT techniques for assembly. Manufacturers must adapt their processes and machinery to handle these smaller components effectively while maintaining quality standards.

Increased Automation

Automation will continue to play a critical role in enhancing manufacturing efficiency within SMT lines. As robotics technology advances, we can expect more sophisticated automated solutions that improve precision, reduce labor costs, and increase overall productivity.

Conclusion

In conclusion, SMT line machines represent a transformative advancement in electronics manufacturing. By automating key processes, these machines enhance production speed, improve product quality, reduce costs, and provide greater flexibility. While challenges such as initial investment costs and supply chain dependencies exist, the long-term benefits far outweigh these concerns. As manufacturers continue to seek ways to optimize their operations, investing in SMT technology will be a crucial step toward achieving higher efficiency and competitiveness in the market.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used in electronics manufacturing where components are mounted directly onto the surface of printed circuit boards (PCBs), allowing for higher density and faster assembly compared to traditional methods.

2. How does an SMT line improve production speed?

SMT lines utilize automated machines like pick-and-place systems that can place thousands of components per hour, significantly speeding up the assembly process compared to manual methods.

3. What are the main components of an SMT line?

The main components include an SMT loader, solder paste printer, pick-and-place machine, reflow oven, and automated optical inspection (AOI) systems.

4. How does using SMT reduce manufacturing costs?

By automating processes, SMT reduces labor costs and minimizes material waste due to fewer errors during assembly. Additionally, faster cycle times lead to increased production capacity.

5. What strategies can be implemented to optimize SMT line efficiency?

Strategies include load balancing across machines, regular maintenance, operator training, data analytics for identifying inefficiencies, and implementing lean manufacturing principles.