Content Menu

● Understanding SMD LED Assembly Machines

>> Key Components and Functions

● How SMD LED Assembly Machines Improve Manufacturing Efficiency

>> 1. Enhanced Production Speed and Throughput

>> 2. Improved Accuracy and Consistency

>> 3. Cost Reduction Through Labor and Material Savings

>> 4. Support for Miniaturization and Complex Designs

>> 5. Scalability and Flexibility

>> 6. Integration with Quality Control Systems

● The SMD LED Assembly Process Using Machines

>> 1. Stencil Printing

>> 2. Component Placement

>> 3. Reflow Soldering

>> 4. Inspection and Testing

>> 5. Cleaning and Secondary Processes

● Benefits of Using SMD LED Assembly Machines

>> Increased Yield and Reliability

>> Reduced Production Costs

>> Enhanced Product Quality

>> Faster Time-to-Market

>> Environmental Advantages

● Future Trends in SMD LED Assembly Machines

● Conclusion

● FAQ

>> 1. What is an SMD LED assembly machine?

>> 2. How does an SMD LED assembly machine improve production speed?

>> 3. Can SMD LED assembly machines handle very small components?

>> 4. What cost savings can be expected by using SMD LED assembly machines?

>> 5. Are SMD LED assembly machines suitable for small-scale production?

In the rapidly evolving electronics manufacturing industry, Surface Mount Device (SMD) LED assembly machines have become indispensable tools for improving production efficiency, quality, and cost-effectiveness. As LED lighting and electronic devices continue to miniaturize and demand higher precision, traditional manual assembly methods fall short in meeting these requirements. This article explores how SMD LED assembly machines enhance manufacturing efficiency, detailing their features, benefits, and the impact on the LED production process.

Understanding SMD LED Assembly Machines

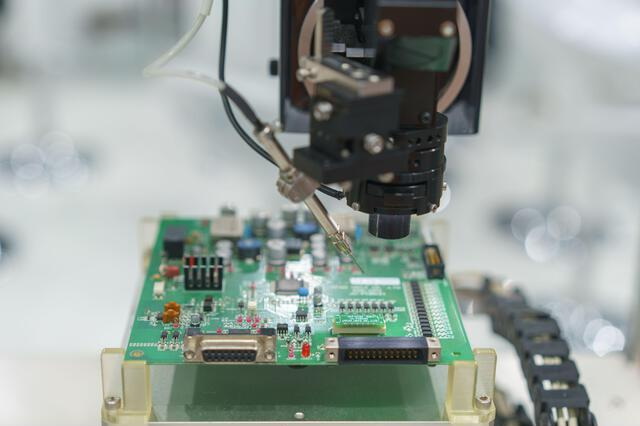

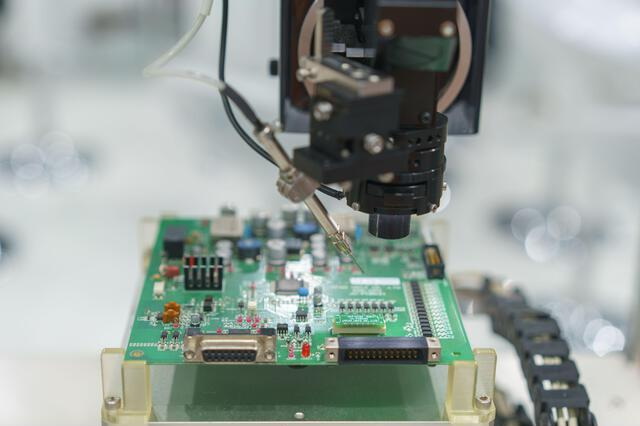

SMD LED assembly machines are specialized equipment designed to automate the placement and soldering of surface mount LEDs and other components onto printed circuit boards (PCBs). These machines typically include several key components such as pick-and-place heads, glue dispensers, die-bonding units, and reflow ovens, all integrated into a streamlined production line.

Key Components and Functions

- Pick-and-Place Machine: Accurately places multiple SMD LEDs and components on the PCB simultaneously, reducing manual errors and increasing speed.

- Glue Dispensing Machine: Applies precise amounts of adhesive to secure components before soldering.

- Die-Bonding Machine: Attaches LED chips to substrates with high precision.

- Reflow Oven: Melts solder paste to form strong, reliable solder joints through controlled heating.

By combining these functions, SMD LED assembly machines facilitate a highly automated, precise, and efficient manufacturing process.

How SMD LED Assembly Machines Improve Manufacturing Efficiency

1. Enhanced Production Speed and Throughput

One of the most significant advantages of using an SMD LED assembly machine is the dramatic increase in production speed. Advanced machines can achieve placement speeds of up to 120,000 components per hour (CPH), which is impossible to match by manual assembly. This speed is achieved through multiple modular placement heads working simultaneously, high-precision servo motors, and optimized software control.

Faster production means manufacturers can meet large orders within shorter lead times, improving customer satisfaction and market competitiveness. Additionally, the ability to run machines continuously with minimal downtime maximizes output and factory utilization.

2. Improved Accuracy and Consistency

Precision is critical in LED assembly because even slight misalignments or poor solder joints can degrade LED performance or cause premature failure. SMD LED assembly machines use vision-guided placement systems with high-resolution cameras to detect component orientation and position in real-time. This ensures that each LED is placed exactly where it needs to be on the PCB.

Consistent placement reduces defects such as tombstoning (where one end of a component lifts off the PCB), skewing, or bridging solder joints. The reduction in defects lowers rework and scrap rates, saving time and materials.

3. Cost Reduction Through Labor and Material Savings

Automating the assembly process with an SMD LED assembly machine reduces the need for manual labor, which can be costly and prone to human error. Labor savings are especially significant in high-volume production environments.

Moreover, precise dispensing of solder paste and adhesives minimizes material waste. Accurate placement reduces the risk of component damage or misplacement, further decreasing scrap rates. Over time, these savings contribute to a lower cost per unit and higher profit margins.

4. Support for Miniaturization and Complex Designs

As LED technology advances, components continue to shrink in size, with some LEDs now as small as 0201 or even smaller. Handling such tiny components manually is challenging and error-prone.

SMD LED assembly machines are designed to handle these miniaturized components with specialized nozzles, feeders, and vision systems. This capability allows manufacturers to produce compact, high-density LED arrays and sophisticated lighting modules that meet modern design standards.

5. Scalability and Flexibility

Modern SMD LED assembly machines offer flexible configurations that can be adapted to different LED types, sizes, and PCB layouts. Manufacturers can quickly switch between product lines or customize production runs without extensive downtime or retooling.

This flexibility is essential for companies that produce multiple LED products or need to respond rapidly to changing market demands. The machines can also be integrated with other automated systems such as automated optical inspection (AOI) and testing stations to create a fully automated production line.

6. Integration with Quality Control Systems

Quality control is vital in LED manufacturing to ensure product reliability and customer satisfaction. Many SMD LED assembly machines now come equipped with inline inspection systems that use cameras and sensors to detect defects immediately after component placement.

This real-time feedback allows operators to correct issues on the spot, reducing the number of defective products moving down the line. Early defect detection saves costs associated with rework, scrap, and warranty claims.

The SMD LED Assembly Process Using Machines

The typical SMD LED assembly process involves several automated steps that collectively enhance efficiency and product quality:

1. Stencil Printing

The process begins with stencil printing, where solder paste is applied to the PCB pads through a metal stencil. The stencil ensures that solder paste is deposited only where components will be placed, with precise thickness and volume.

2. Component Placement

Next, the SMD LED assembly machine places LEDs and other components onto the solder-pasted PCB. The pick-and-place heads use vacuum nozzles to pick components from feeders and position them with micron-level accuracy.

3. Reflow Soldering

The PCB is then passed through a reflow oven, where the solder paste melts and solidifies to form strong electrical and mechanical connections. The oven's temperature profile is carefully controlled to prevent damage to sensitive LEDs and ensure optimal solder joint quality.

4. Inspection and Testing

After soldering, the PCB undergoes automated optical inspection (AOI) to verify component placement and solder joint quality. Some production lines also include electrical testing to verify LED functionality.

5. Cleaning and Secondary Processes

Finally, residual flux is cleaned from the PCB surface, and protective coatings may be applied to enhance durability and environmental resistance.

Benefits of Using SMD LED Assembly Machines

Increased Yield and Reliability

Automation reduces variability and defects, resulting in higher yields and more reliable LED products. Consistent quality improves brand reputation and customer satisfaction.

Reduced Production Costs

Lower labor costs, minimized material waste, and faster production cycles combine to reduce overall manufacturing expenses, improving profitability.

Enhanced Product Quality

Precise placement and soldering improve LED performance, longevity, and aesthetic appeal, which are critical factors for lighting and display applications.

Faster Time-to-Market

High-speed assembly lines enable manufacturers to respond quickly to market trends and customer demands, launching new products faster.

Environmental Advantages

Precise material usage reduces waste, and automated processes often consume less energy than manual methods, contributing to greener manufacturing.

Future Trends in SMD LED Assembly Machines

As LED technology continues to evolve, SMD LED assembly machines are also advancing. Some emerging trends include:

- Artificial Intelligence (AI) Integration: AI-powered vision systems can improve defect detection and predictive maintenance, reducing downtime.

- IoT Connectivity: Machines connected to the Internet of Things (IoT) enable real-time monitoring, remote diagnostics, and data-driven process optimization.

- Multi-Function Machines: Combining placement, soldering, and inspection into a single compact system to save space and improve workflow.

- Advanced Materials Handling: Improved feeders and nozzles designed for new LED package types and substrates.

These innovations will further enhance manufacturing efficiency, quality, and flexibility.

Conclusion

SMD LED assembly machines are transformative in enhancing manufacturing efficiency for LED lighting and electronic device producers. By automating critical assembly steps, these machines deliver faster production speeds, higher accuracy, reduced costs, and improved product quality. Their ability to handle miniaturized components and complex designs makes them essential for modern LED manufacturing. As technology advances, the role of SMD LED assembly machines will only grow, driving innovation and competitiveness in the electronics industry.

FAQ

1. What is an SMD LED assembly machine?

An SMD LED assembly machine is an automated system designed to place and solder surface mount LEDs and other components onto PCBs with high precision and speed.

2. How does an SMD LED assembly machine improve production speed?

These machines use multiple high-speed placement heads and advanced servo motors to place thousands of components per hour, significantly increasing throughput compared to manual assembly.

3. Can SMD LED assembly machines handle very small components?

Yes, modern machines can handle components as small as 0201 size, enabling the production of compact and intricate LED lighting designs.

4. What cost savings can be expected by using SMD LED assembly machines?

Cost savings come from reduced labor requirements, minimized material waste, lower defect rates, and faster production cycles, all contributing to improved manufacturing economics.

5. Are SMD LED assembly machines suitable for small-scale production?

While highly efficient for large volumes, many machines offer flexible configurations and offline programming, allowing them to be adapted for small to medium production runs as well.