Content Menu

● Introduction

● Understanding Lean Manufacturing

● Key Benefits of Lean Manufacturing in SMT

>> Enhanced Operator Efficiency

>> Waste Reduction

>> Improved Workflow

>> Quality Assurance

● Implementing Lean Principles in SMT

● Case Studies: Successful Lean Implementation in SMT

● Challenges in Implementing Lean Manufacturing

● Conclusion

● FAQ

>> 1. What is lean manufacturing?

>> 2. How does lean manufacturing improve operator efficiency?

>> 3. What are the key principles of lean manufacturing?

>> 4. How can SMT manufacturers implement lean principles?

>> 5. What are the benefits of lean manufacturing in SMT?

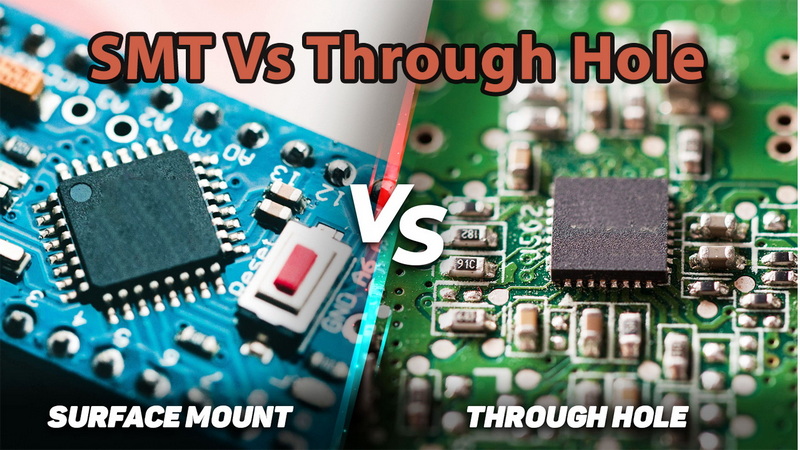

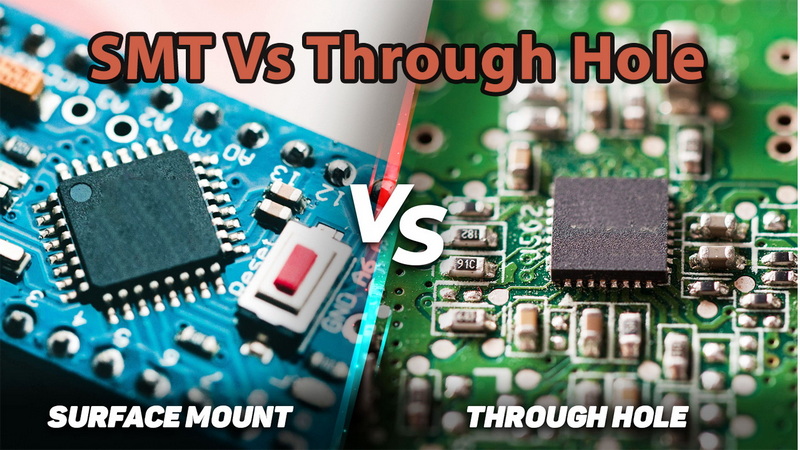

Introduction

Lean manufacturing has transformed various industries by focusing on waste reduction and enhancing efficiency. In the realm of Surface Mount Technology (SMT) manufacturing, these principles can significantly boost operator efficiency and overall production outcomes. This article delves into how lean manufacturing can be applied to SMT production to achieve remarkable efficiency gains.

Understanding Lean Manufacturing

Lean manufacturing is a methodology that emphasizes the minimization of waste while maximizing value for the customer. Key principles include:

- Continuous improvement

- Waste elimination

- Streamlined workflows

By integrating these principles, SMT manufacturers can optimize their processes and improve operator efficiency.

Key Benefits of Lean Manufacturing in SMT

Enhanced Operator Efficiency

Training and education are pivotal in lean manufacturing. By equipping operators with the necessary skills, SMT manufacturers can reduce errors and improve productivity. Continuous training ensures that operators stay updated with the latest techniques and technologies.

Waste Reduction

Lean manufacturing identifies and eliminates non-value-added activities. In SMT production, this could mean reducing excess inventory, minimizing material waste, and optimizing machine usage. These practices not only save costs but also enhance environmental sustainability.

Improved Workflow

Implementing continuous flow in SMT production ensures that products move seamlessly through each stage without interruptions. This reduces lead times, prevents bottlenecks, and enhances overall efficiency.

Quality Assurance

Lean manufacturing emphasizes quality at every stage. By integrating real-time monitoring and automation, SMT manufacturers can detect and address defects promptly, ensuring high-quality outputs.

Implementing Lean Principles in SMT

To successfully adopt lean manufacturing in SMT, manufacturers should:

- Invest in advanced automation technologies.

- Conduct regular training sessions for operators.

- Utilize tools like value stream mapping to identify inefficiencies.

- Foster a culture of continuous improvement.

Case Studies: Successful Lean Implementation in SMT

Several companies have successfully implemented lean principles in their SMT processes:

- Company A reduced setup times by 50% through standardized work procedures.

- Company B achieved a 30% increase in production output by implementing a pull system for materials.

- Company C improved defect rates by utilizing real-time monitoring systems.

These examples highlight the tangible benefits of adopting lean practices in SMT manufacturing.

Challenges in Implementing Lean Manufacturing

While the benefits of lean manufacturing are significant, challenges may arise during implementation:

- Resistance to change from employees

- Initial costs associated with training and technology upgrades

- Difficulty in measuring improvements consistently

Addressing these challenges requires strong leadership commitment and clear communication throughout the organization.

Conclusion

Lean manufacturing offers a transformative approach to enhancing SMT production efficiency. By focusing on waste reduction, operator efficiency, and continuous improvement, SMT manufacturers can achieve superior productivity and quality. Embracing these principles not only benefits the business but also contributes to a sustainable and competitive manufacturing environment.

FAQ

1. What is lean manufacturing?

Lean manufacturing is a methodology that focuses on minimizing waste and maximizing value for the customer through continuous improvement and efficient workflows.

2. How does lean manufacturing improve operator efficiency?

By providing training and education, lean manufacturing equips operators with the skills needed to perform tasks efficiently, reducing errors and enhancing productivity.

3. What are the key principles of lean manufacturing?

The key principles include waste elimination, continuous improvement, and streamlined workflows.

4. How can SMT manufacturers implement lean principles?

SMT manufacturers can implement lean principles by investing in automation, conducting operator training, and using tools like value stream mapping to identify inefficiencies.

5. What are the benefits of lean manufacturing in SMT?

Benefits include enhanced operator efficiency, reduced waste, improved workflow, and superior quality assurance.