Content Menu

● Introduction to SMT PCB Assembly

>> Key Steps in SMT PCB Assembly

● Quality Control Measures in SMT PCB Assembly

>> Visual Inspection (VI)

>> Automated Optical Inspection (AOI)

>> X-ray Inspection

>> Solder Paste Inspection (SPI)

>> In-Circuit Testing (ICT)

>> Environmental Testing

● Best Practices for Ensuring Quality in SMT Assembly

>> Design for Manufacturability (DFM)

>> Statistical Process Control (SPC)

>> Poka-Yoke (Error-Proofing)

>> Process Documentation and Standardization

>> Regular Calibration and Maintenance

● Advanced Testing Techniques

>> Boundary Scan Testing

>> Machine Learning in Defect Detection

● Recent Advancements in SMT Techniques

>> Sustainability Trends in SMT PCBA Manufacturing

● Streamlining the Assembly Process

● Ensuring Accuracy and Reliability

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What is the role of Automated Optical Inspection (AOI) in SMT PCB assembly?

>> 2. How does X-ray inspection contribute to quality control in SMT assembly?

>> 3. What are the benefits of implementing Design for Manufacturability (DFM) in SMT PCB design?

>> 4. How does Statistical Process Control (SPC) help in maintaining quality in SMT assembly?

>> 5. What is the importance of regular equipment calibration in SMT assembly?

● Citations:

Ensuring quality control in Surface Mount Technology (SMT) PCB assembly processes is crucial for producing reliable and efficient electronic devices. SMT has become the dominant method for assembling printed circuit boards (PCBs) due to its precision, speed, and cost-effectiveness. However, maintaining high-quality standards requires careful attention to each stage of the assembly process. This article will delve into the key strategies and techniques for ensuring quality control in SMT PCB assembly.

Introduction to SMT PCB Assembly

SMT PCB assembly involves mounting electronic components directly onto the surface of a PCB using solder paste and reflow soldering. This method offers several advantages over traditional through-hole technology, including higher component density, reduced production time, and lower manufacturing costs. However, the smaller size of components and the complexity of the assembly process introduce challenges in maintaining quality.

Key Steps in SMT PCB Assembly

1. PCB Preparation: Ensuring the PCB is clean and free of defects is essential. The PCB design should be optimized for manufacturability, considering factors like component spacing and solder pad sizes.

2. Solder Paste Application: This step involves applying solder paste to the PCB pads using a stencil. Consistent and precise solder paste deposition is vital for forming reliable solder joints.

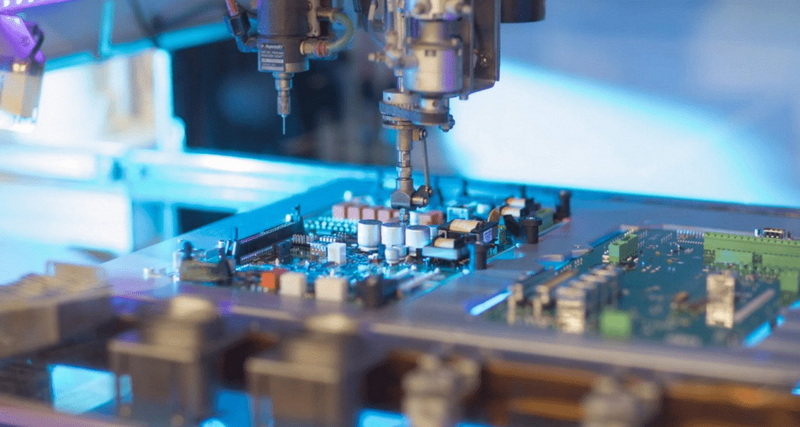

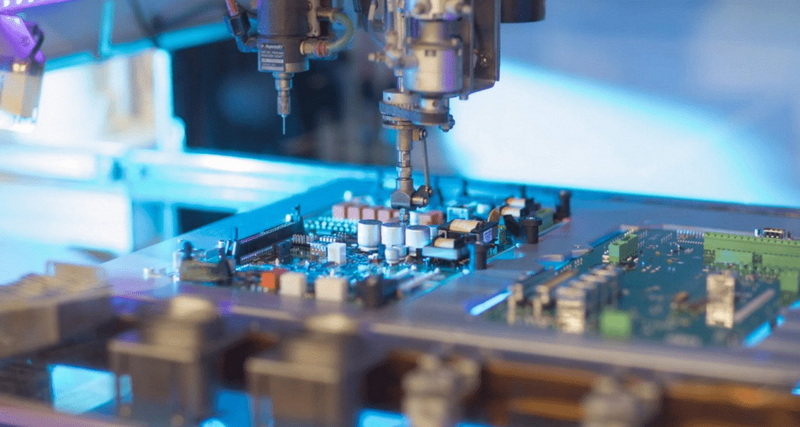

3. Component Placement: Automated pick-and-place machines are used to position components onto the solder paste. Precision in component placement is critical to prevent misalignments and ensure proper soldering.

4. Reflow Soldering: The PCB is then heated in a reflow oven to melt the solder paste, creating a bond between the components and the PCB.

5. Inspection and Testing: Various inspection techniques are employed to detect defects and ensure the assembly meets quality standards.

Quality Control Measures in SMT PCB Assembly

Visual Inspection (VI)

Visual inspection is a fundamental quality control measure, involving the examination of PCBs under magnification to identify defects such as misaligned components, solder bridges, or insufficient solder coverage. Automated Optical Inspection (AOI) systems enhance this process by using high-resolution images and sophisticated algorithms to detect anomalies more efficiently.

Automated Optical Inspection (AOI)

AOI systems are essential for verifying component placement, solder paste distribution, and weld joint quality. They can detect issues like missing or misaligned components, solder bridges, and cold solder joints, ensuring only flawless assemblies proceed to the next stage.

X-ray Inspection

X-ray inspection is particularly useful for inspecting hidden solder joints beneath components like Ball Grid Arrays (BGAs). It reveals internal defects such as voids, cracks, and solder bridges that are not visible through optical means.

Solder Paste Inspection (SPI)

SPI ensures uniform and consistent solder deposition before component placement, preventing issues like solder bridges and insufficient solder coverage.

In-Circuit Testing (ICT)

ICT evaluates the electrical functionality of individual components and their connections on the PCB. It detects issues like open circuits and short circuits, which can prevent functional failures.

Environmental Testing

Environmental testing exposes products to extreme conditions such as temperature and humidity to assess their durability and operational reliability.

Best Practices for Ensuring Quality in SMT Assembly

Design for Manufacturability (DFM)

Implementing DFM principles early in the product development cycle can significantly improve SMT assembly quality. This includes optimizing component placement, standardizing pad layouts, and ensuring adequate spacing for inspection and rework.

Statistical Process Control (SPC)

SPC techniques help identify and address process variations before they lead to quality issues. Tools like control charts and capability analysis are used to monitor critical parameters and assess process stability.

Poka-Yoke (Error-Proofing)

Implementing error-proofing mechanisms can prevent common assembly mistakes. Examples include barcode scanning for component verification and automated optical alignment for stencil printing.

Process Documentation and Standardization

Developing comprehensive process documentation ensures consistency across production runs. This includes detailed work instructions, process flow charts, equipment setup parameters, and quality check procedures.

Regular Calibration and Maintenance

Regular calibration of assembly equipment and adherence to industry standards like IPC-A-610 enhance product consistency and reliability.

Advanced Testing Techniques

Boundary Scan Testing

Boundary scan testing assesses the functionality of digital components on the PCB, using built-in boundary scan cells to diagnose faults without physical probing.

Machine Learning in Defect Detection

Machine learning algorithms can analyze large data sets to predict failure patterns and improve test accuracy, enhancing the quality assurance process.

Recent Advancements in SMT Techniques

Recent advancements in SMT techniques have significantly enhanced precision and efficiency in PCB assembly. The integration of advanced optimization software allows for real-time data analysis and feedback during the assembly process, ensuring any deviations from expected performance metrics can be promptly rectified. High-resolution imaging systems have become essential for achieving finer alignment during component placement, contributing to the overall accuracy of the assembly. Additionally, advancements in automation technologies, such as robotic placing tools, have diminished human error in the SMT process, enhancing the quality and scalability of production.

Sustainability Trends in SMT PCBA Manufacturing

The emphasis on sustainability within the SMT PCBA manufacturing landscape has become increasingly pronounced. Industry stakeholders are recognizing the importance of adopting environmentally friendly practices to minimize waste and energy consumption during PCB assembly processes. A significant trend is the use of lead-free soldering, which not only aligns with regulatory requirements but also promotes a healthier environment. Moreover, manufacturers are exploring recyclable materials for boards and components, reducing their ecological footprint while maintaining the integrity of their products. Energy-efficient machinery and renewable energy sources are being integrated into production lines to bolster overall efficiency without compromising production speed.

Streamlining the Assembly Process

Streamlining the assembly process in Surface Mount Technology is crucial for improving efficiency and reducing production costs. One effective approach is the implementation of automated assembly lines, which enhance precision and speed. Automated pick-and-place machines can accurately position components on PCBs, significantly minimizing human error. Integrating optical inspection systems ensures defects are identified and corrected early in the assembly process, reducing rework and scrap rates. Another key practice is optimizing the solder paste application. Consistent and precise deposition of solder paste is vital for forming reliable solder joints, which is achievable through well-maintained stencil printing processes.

Ensuring Accuracy and Reliability

Ensuring accuracy and reliability in SMT assembly is paramount to achieving high-quality electronics. Precision in component placement is a critical factor, as even slight misalignments can lead to circuit malfunctions. Automated optical inspection (AOI) systems are essential tools that verify component positioning and detect solder bridge defects, ensuring only flawless assemblies proceed to the next stage. Additionally, the use of controlled reflow soldering processes helps maintain consistent solder joint quality. By carefully monitoring temperature profiles, manufacturers can prevent common issues such as overheating or cold solder joints, which compromise reliability.

Conclusion

Ensuring quality control in SMT PCB assembly processes is multifaceted and requires careful attention to design, assembly, inspection, and testing stages. By implementing robust quality control measures, manufacturers can produce high-quality electronic devices that meet stringent industry standards. Continuous improvement through employee training, process optimization, and adherence to industry standards is crucial for maintaining quality and reliability in SMT PCB assembly.

Frequently Asked Questions (FAQs)

1. What is the role of Automated Optical Inspection (AOI) in SMT PCB assembly?

AOI plays a critical role in SMT PCB assembly by verifying component placement, solder paste distribution, and weld joint quality. It detects defects such as missing or misaligned components, solder bridges, and cold solder joints, ensuring only flawless assemblies proceed to the next stage.

2. How does X-ray inspection contribute to quality control in SMT assembly?

X-ray inspection is particularly useful for inspecting hidden solder joints beneath components like Ball Grid Arrays (BGAs). It reveals internal defects such as voids, cracks, and solder bridges that are not visible through optical means, ensuring the integrity of solder joints.

3. What are the benefits of implementing Design for Manufacturability (DFM) in SMT PCB design?

Implementing DFM principles early in the product development cycle can significantly improve SMT assembly quality. This includes optimizing component placement, standardizing pad layouts, and ensuring adequate spacing for inspection and rework, which enhances manufacturing yield and reduces the risk of defects.

4. How does Statistical Process Control (SPC) help in maintaining quality in SMT assembly?

SPC techniques help identify and address process variations before they lead to quality issues. Tools like control charts and capability analysis are used to monitor critical parameters and assess process stability, ensuring consistent product quality.

5. What is the importance of regular equipment calibration in SMT assembly?

Regular calibration of assembly equipment is essential for maintaining precision and consistency in the assembly process. It ensures that machines operate within specified tolerances, reducing errors and improving overall product reliability.

Citations:

[1] https://www.linkedin.com/pulse/whats-eight-pillars-smt-assembly-quality-assurance-cindy-zhang-5elpc

[2] https://www.andwinpcb.com/advancements-in-smt-pcba-manufacturing-techniques-and-trends/

[3] https://vohrum.com/from-concept-to-completion-best-practices-in-smt-design-assembly-and-testing-for-high-performance-pcbs/

[4] https://www.ednasia.com/top-12-incredible-techniques-to-control-the-quality-of-pcb-smt-assembly/

[5] https://www.raypcb.com/effective-measures-to-improve-smt-assembly-quality/

[6] https://www.electronicdesign.com/markets/automation/article/21176834/technotronix-6-best-practices-for-a-smoother-pcb-assembly-process

[7] https://www.neodensmt.com/news/quality-control-during-smt-pcb-assembly-manufa-17136737.html

[8] https://www.andwinpcb.com/pcb-smt-assembly-techniques-for-streamlined-production/

[9] https://asselems.com/en/best-practices-in-smt-assembly

[10] https://www.7pcb.com/blog/smt-assembly-quality-related-standards

[11] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[12] https://www.linkedin.com/pulse/unveiling-eight-pillars-smt-assembly-quality-assurance-alice-wu-kusec

[13] https://www.ipcb.com/technical/3363.html

[14] https://www.technotronix.us/pcbblog/top-trends-in-printed-circuit-board-manufacturing-for-2024/

[15] https://www.viasion.com/blog/must-have-qualities-of-a-reliable-smt-pcb-assembly-supplier/

[16] https://www.pcbcart.com/article/content/evaluate-smt-assembler-capability.html

[17] https://www.pcbgogo.com/Article/Innovations_in_printed_circuit_board_assembly__trends_and_techniques.html

[18] https://www.hemeixinpcb.com/company/news/understanding-the-pcb-assembly-process-a-comprehensive-guide.html

[19] https://www.pcbcart.com/article/content/measures-to-improve-smt-assembly-quality.html

[20] https://www.pcbasic.com/blog/top_pcb_assembly.html