Content Menu

● Introduction to SMT Reel Quantity Calculation

>> Using SMT Reel Quantity Calculators

>> Manual Estimation Methods

>> Weight Estimation Method

>> Automated Counting Devices

>> Reel Estimator Apps

● Advantages of Accurate SMT Reel Quantity Calculation

● Challenges in SMT Reel Quantity Calculation

● Impact of Accurate SMT Reel Quantity Calculation on Production Costs

>> Material Costs in SMT Assembly

>> Labor and Equipment Costs

● Real-Time Inventory Management Systems

>> ERP/MRP Systems Integration

● Conclusion

● FAQ

>> 1. What is an SMT reel quantity calculator, and how does it work?

>> 2. What are the advantages of using automated SMT reel counters?

>> 3. How accurate are manual estimation methods compared to automated tools?

>> 4. Can SMT reel quantity calculators be used for all types of reels?

>> 5. What are the common challenges faced in calculating SMT reel quantities?

● Citations:

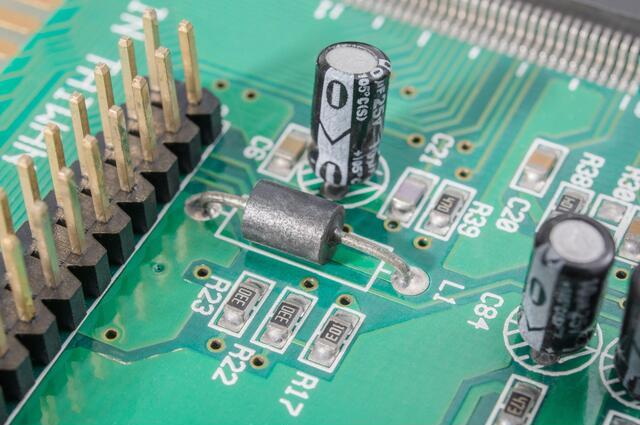

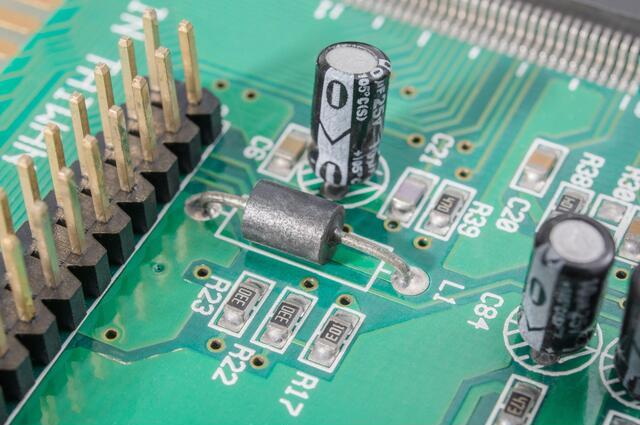

Accurate calculation of SMT (Surface Mount Technology) reel quantities is crucial for efficient project management in the electronics manufacturing industry. This involves understanding the components on a reel, ensuring sufficient stock for production, and minimizing waste. In this article, we will explore various methods and tools available for calculating SMT reel quantities, including the use of SMT reel quantity calculators.

Introduction to SMT Reel Quantity Calculation

SMT components are typically supplied on reels, which are wound with a carrier tape that holds the components in place. The tape is covered with a protective cover tape to prevent damage and contamination. Calculating the number of components on a reel involves several key factors:

- Reel dimensions: The diameter of the reel core (hub) and the outer diameter of the wound tape.

- Tape thickness: The thickness of the carrier tape.

- Component spacing: The distance between components on the tape, known as the pitch.

- Number of windings: The number of layers of tape wound around the reel.

Using SMT Reel Quantity Calculators

One of the most efficient ways to calculate SMT reel quantities is by using an SMT reel quantity calculator. These calculators are available online and can be accessed through websites like CompuPhase, which provides a detailed formula-based approach to estimate the number of components on a reel.

Manual Estimation Methods

For those without access to a calculator or who prefer a more hands-on approach, manual estimation methods can be used. These methods involve measuring the reel dimensions and tape thickness manually and then applying the formulas.

However, manual methods can be less accurate due to measurement errors and the assumption that the tape is tightly wound. The use of digital calipers can improve accuracy, but even with these tools, there may be a tolerance of ±0.2 mm, which can lead to significant errors in tape thickness measurements[1].

Weight Estimation Method

Another traditional method for estimating component quantities is the weight estimation method. This involves weighing a known quantity of components (e.g., 100 pieces) and then weighing the total batch. The total number of components is estimated by dividing the total weight by the weight of the known quantity.

However, this method is less accurate and more time-consuming compared to using an SMT reel quantity calculator or automated counting devices.

Automated Counting Devices

For high precision and efficiency, automated counting devices such as SMT reel counters are recommended. These devices use mechanical or X-ray technology to accurately count components on a reel. They are particularly useful for managing inventory and ensuring accurate stock levels.

Reel Estimator Apps

In addition to online calculators and automated devices, there are also mobile apps available for estimating SMT reel quantities. For example, the Reel Estimator app for iOS devices allows users to estimate the remaining number of parts on a reel by inputting the necessary measurements.

Advantages of Accurate SMT Reel Quantity Calculation

Accurate calculation of SMT reel quantities offers several benefits:

- Efficient Inventory Management: Knowing exactly how many components are available helps in planning production runs and ordering supplies.

- Reduced Waste: Avoids over-ordering components, which can save costs and reduce waste.

- Improved Production Planning: Ensures that there are enough components for each production batch, reducing downtime due to stockouts.

Challenges in SMT Reel Quantity Calculation

Despite the availability of calculators and automated tools, challenges remain:

- Measurement Accuracy: Small measurement errors can lead to significant discrepancies in estimated quantities.

- Tape Winding Variability: Loosely wound tapes can result in overestimation of component quantities.

- Component Variability: Different component sizes and pitches require adjustments in calculations.

Impact of Accurate SMT Reel Quantity Calculation on Production Costs

Accurate SMT reel quantity calculation plays a crucial role in managing production costs. By ensuring that the right amount of components is ordered and used, manufacturers can avoid unnecessary expenses associated with excess inventory or stockouts. This is particularly important in SMT assembly, where material costs are a significant portion of the overall expense[7].

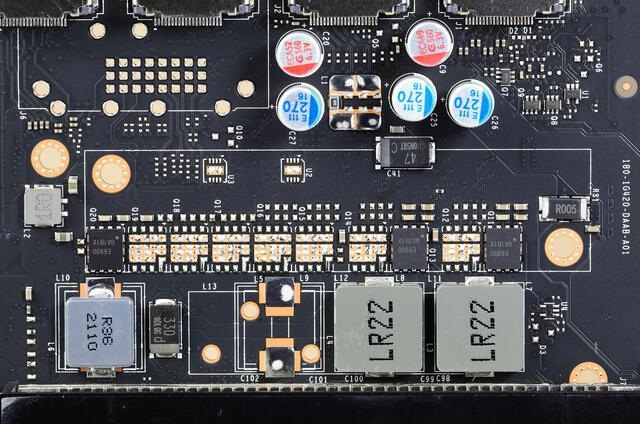

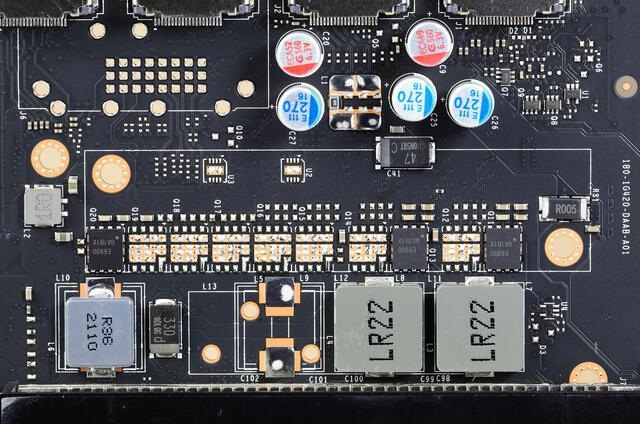

Material Costs in SMT Assembly

Material costs include the cost of components, PCBs, and other consumables. Accurate inventory management helps in optimizing these costs by ensuring that components are not wasted or over-ordered. This is especially critical for high-value components or those with long lead times.

Labor and Equipment Costs

While labor and equipment costs are not directly influenced by reel quantity calculations, efficient inventory management can reduce labor costs by minimizing the time spent on manual counting and inventory adjustments. Additionally, accurate component quantities help in optimizing production runs, which can lead to better equipment utilization and reduced setup costs.

Real-Time Inventory Management Systems

Implementing real-time inventory management systems can further enhance the benefits of accurate SMT reel quantity calculations. These systems allow for continuous monitoring of stock levels, enabling prompt reordering when necessary and reducing the likelihood of stockouts or overstocking[2].

ERP/MRP Systems Integration

ERP (Enterprise Resource Planning) and MRP (Material Requirements Planning) systems are essential for managing production workflows. However, these systems often lack detailed tracking of physical inventory units like reels or sticks. Integrating real-time inventory tracking with ERP/MRP systems can provide a more accurate view of available stock, improving production planning and reducing waste.

Conclusion

Accurate calculation of SMT reel quantities is essential for efficient electronics manufacturing. By using SMT reel quantity calculators, manual estimation methods, or automated counting devices, manufacturers can ensure precise inventory management and reduce production costs. While challenges exist, advancements in technology continue to improve the accuracy and efficiency of these calculations.

FAQ

1. What is an SMT reel quantity calculator, and how does it work?

An SMT reel quantity calculator is a tool used to estimate the number of components on a reel by inputting the reel's dimensions, tape thickness, and component pitch. It works by calculating the number of windings and then the total length of tape, which is divided by the component pitch to find the total number of components.

2. What are the advantages of using automated SMT reel counters?

Automated SMT reel counters offer high accuracy, speed, and efficiency in counting components. They can connect to enterprise systems for real-time inventory management and reduce labor costs by automating the counting process.

3. How accurate are manual estimation methods compared to automated tools?

Manual estimation methods are generally less accurate than automated tools. They rely on precise measurements and assumptions about tape winding, which can lead to errors. Automated tools, especially those using X-ray technology, provide much higher accuracy and reliability.

4. Can SMT reel quantity calculators be used for all types of reels?

Most SMT reel quantity calculators are designed to work with standard reel sizes and tape configurations. However, they may require adjustments for non-standard reels or specialized tapes. Some calculators, like those from CompuPhase, can handle various reel sizes and tape thicknesses.

5. What are the common challenges faced in calculating SMT reel quantities?

Common challenges include measurement accuracy, variability in tape winding, and differences in component sizes and pitches. These factors can lead to discrepancies in estimated quantities if not properly accounted for.

Citations:

[1] https://www.compuphase.com/electronics/reelestimate.htm

[2] https://www.ipc.org/system/files/technical_resource/E6&S30_02.pdf

[3] https://www.seamarkzm.com/common-challenges-and-errors-in-manual-smd-reel-counting.html

[4] https://electronics.stackexchange.com/questions/627290/how-to-estimate-the-number-of-components-on-a-tape-reel

[5] https://kicthermal.com/wp-content/uploads/2012/11/Process-Guidelines-to-Ensure-Optimal-SMT-Electronics-Assembly-98776-R0.pdf.pdf

[6] https://www.circuitinsight.com/pdf/improve_smt_assembly_yields_root_cause_analysis_ipc.pdf

[7] https://www.anypcba.com/blogs/pcb-assembly-knowledge/understanding-smt-assembly-cost-a-comprehensive-guide.html

[8] https://fctassembly.wordpress.com/technical-resources/technical-papers/smt-assembly-challenges-and-proven-solutions-for-improving-yields/

[9] https://blog.minicircuits.com/small-quantity-tape-and-reel-splicing/

[10] https://www.pcbcart.com/article/content/evaluate-smt-assembler-capability.html

[11] https://www.protoexpress.com/kb/kitting-guidelines/

[12] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[13] https://www.andwinpcba.com/oint615/

[14] https://www.onsemi.com/pub/collateral/brd8011-d.pdf

[15] https://www.epsprogramming.com/blog/challenges-component-packaging-assembly-line/

[16] https://www.mdpi.com/2306-5729/10/2/16

[17] https://www.pcbcart.com/article/content/measures-to-improve-smt-assembly-quality.html

[18] https://ceur-ws.org/Vol-3455/invited1.pdf

[19] https://picamfg.com/navigating-smt-assembly-methods-for-flexible-circuits/

[20] https://media.melexis.com/-/media/files/documents/application-notes/handling-and-assembly/guidelines-surface-mount-technology-smt-soldering-application-note-melexis.pdf?ts=20211210t1215226325