Content Menu

● Introduction to PCB Stencils

>> Types of PCB Stencils

● Benefits of Using PCB Stencils

● Materials Used for PCB Stencils

● Choosing the Right PCB Stencil

● The Role of PCB Stencils in Custom Electronic Design

● Innovations in PCB Stencil Technology

>> Multi-Level Stencils

>> Advanced Materials and Techniques

● Impact of PCB Stencils on Production Costs

>> Cost Comparison: Stencil Printing vs. Jet-Based Printing

● PCB Assembly Costs and Optimization Strategies

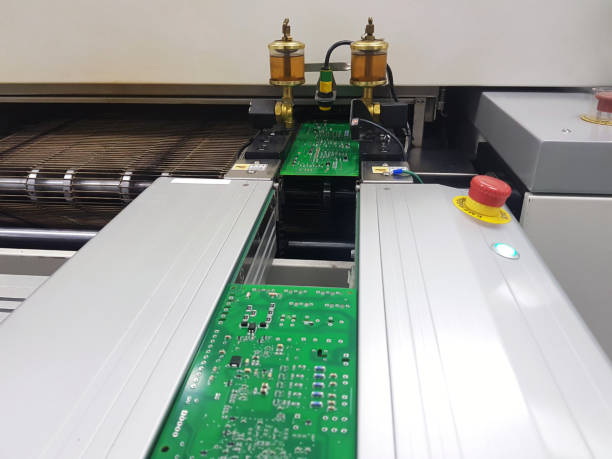

● The Role of Stencils in SMT Precision and Efficiency

● Advanced PCB and Stencil Services

● Conclusion

● FAQs

>> 1. What is the primary function of an Express PCB SMT Stencil?

>> 2. How do PCB stencils improve production efficiency?

>> 3. What materials are commonly used for PCB stencils?

>> 4. What factors influence the choice of PCB stencil thickness?

>> 5. Can PCB stencils be reused?

● Citations:

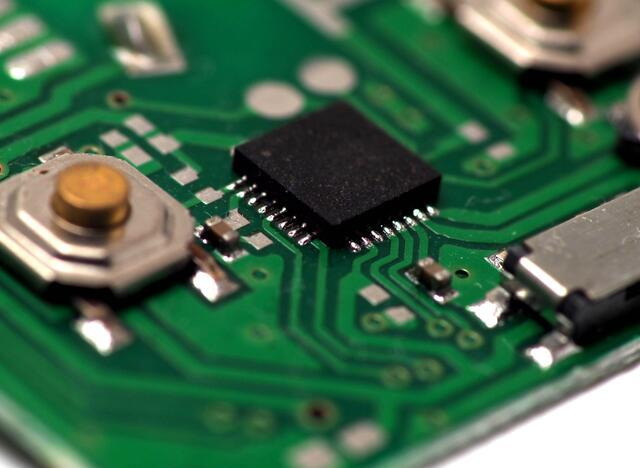

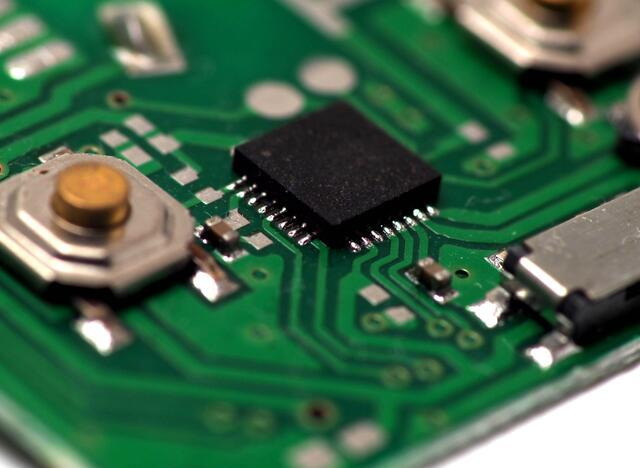

In the realm of electronic manufacturing, precision and efficiency are paramount. One crucial tool that has revolutionized the production process is the Express PCB SMT Stencil. This article delves into the world of PCB stencils, exploring their role in enhancing production efficiency, their types, materials, and the benefits they offer in the context of Surface Mount Technology (SMT).

Introduction to PCB Stencils

A PCB stencil is a thin sheet, typically made of materials like stainless steel or polyimide, with precision-cut apertures that match the solder pads of a PCB layout. The primary function of a stencil is to ensure accurate and consistent application of solder paste onto the PCB before component placement. This controlled deposition prevents issues such as bridging, insufficient solder, or excessive paste, which can lead to defects in the final assembly.

Types of PCB Stencils

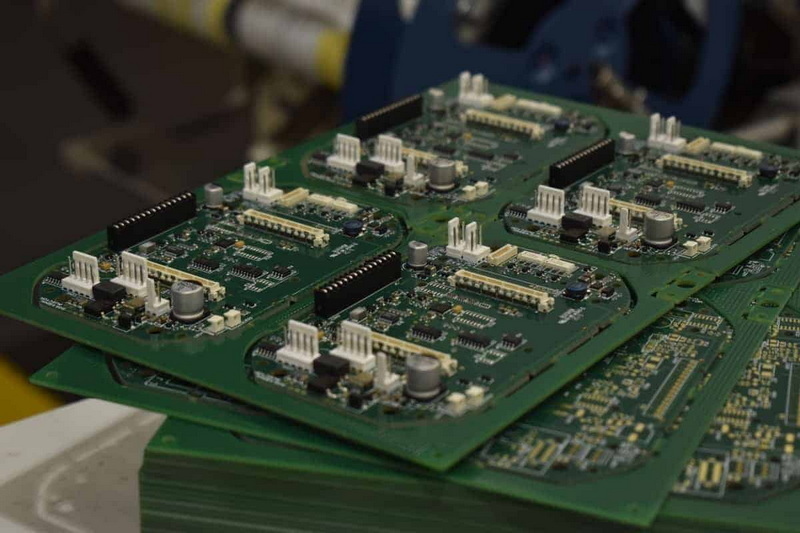

There are several types of PCB stencils, each designed for specific applications and production scales:

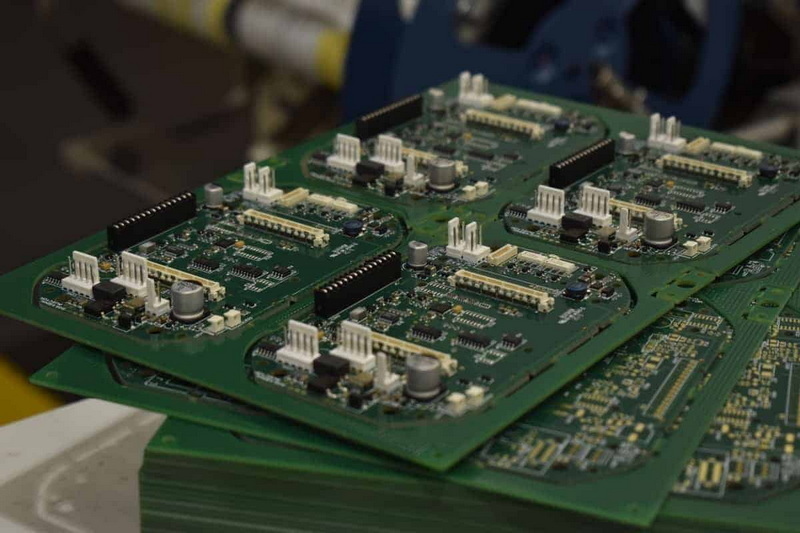

- Framed Stencils: These stencils are permanently mounted in a frame and have a taut mesh backing to ensure stability. They are commonly used for high-volume production where consistency and durability are essential. Framed stencils are more expensive due to the additional frame support but offer better alignment and reusability.

- Frameless Stencils: Also known as foils, these are laser-cut solder paste stencils designed to work with stencil tensioning systems. They are less expensive and ideal for low-volume prototyping or small batch productions.

- Step Stencils: These stencils have varying thicknesses across different sections, allowing for the application of different solder paste volumes to accommodate components of varying sizes on the same PCB.

Benefits of Using PCB Stencils

The use of PCB stencils in SMT assembly offers numerous benefits that significantly improve production efficiency:

- Improved Accuracy and Consistency: Stencils provide uniform solder paste deposition, reducing the likelihood of defects caused by uneven application. This consistency is crucial for maintaining high-quality standards across multiple PCBs.

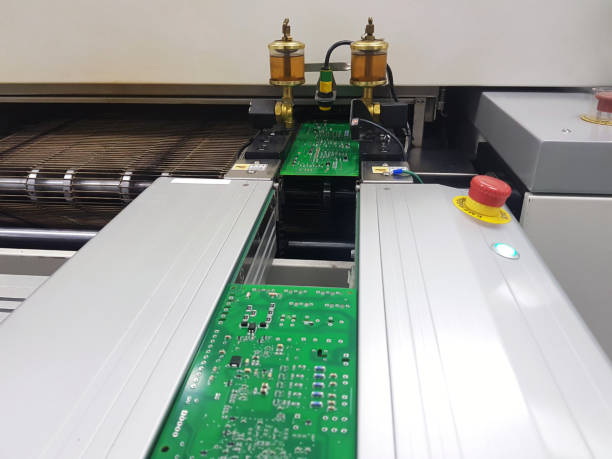

- Increased Production Efficiency: Automating the paste application process with stencils speeds up manufacturing, reducing labor costs and improving throughput. Compared to manual methods, stencils enable faster solder paste application, allowing for higher production volumes in less time.

- Reduced Material Waste: Precisely cut apertures minimize excess solder paste, leading to cost savings and a cleaner manufacturing environment. This efficiency in material usage is particularly beneficial for high-volume production runs.

- Enhanced Reliability in Electronic Product Development: Proper solder paste application leads to stronger solder joints, improving the longevity and performance of electronic assemblies. This reliability is critical for ensuring that electronic devices function as intended over their lifespan.

Materials Used for PCB Stencils

PCB stencils can be made from a variety of materials, each selected for its unique properties to meet different production needs:

- Stainless Steel: This is the most widely used material due to its high durability and precision. It is resistant to corrosion and wear, making it ideal for high-volume production runs.

- Nickel: Nickel stencils, particularly electroformed ones, offer improved paste release properties and a longer lifespan. They are suitable for ultra-fine pitch applications.

- Polyimide: This material is used for flexible stencils, which are beneficial for prototyping or low-volume production.

Choosing the Right PCB Stencil

Selecting the appropriate PCB stencil depends on several factors:

- Component Density: Fine-pitch components require high-precision stencils, such as electroformed or laser-cut types.

- Production Volume: High-volume production benefits from framed stencils, while low-volume prototyping may use frameless or flexible polyimide stencils.

- Stencil Thickness: The thickness of the stencil determines the volume of solder paste applied. Typically, 100–150 microns are used for standard PCBs, while finer pitches may require thinner stencils.

The Role of PCB Stencils in Custom Electronic Design

Custom electronic design often requires tailored PCB manufacturing processes to meet specific performance requirements. Companies like Arshon Technology utilize PCB stencils to enhance precision and efficiency in assembling custom PCBs. Whether developing complex multilayer boards or fine-pitch surface mount devices, using high-quality stencils ensures that each PCB meets stringent design and performance standards.

Innovations in PCB Stencil Technology

With advancements in electronic product development, the demand for more precise and reliable PCB assembly processes is growing. Innovations such as nano-coating on stencils are improving solder paste release and reducing cleaning cycles, further enhancing efficiency. Additionally, automation in stencil-based solder paste application continues to evolve, enabling even greater precision and repeatability in manufacturing.

Multi-Level Stencils

Multi-level stencils are a strategic tool in the production of high-precision and high-quality PCBs, playing a crucial role in the electronics industry. These stencils, known for their complex structure and multiple layers, enable precise material application, such as solder paste, in different areas of the PCB. Recent advancements include the use of advanced materials and improved lithography techniques to create more precise patterns and reduce hole sizes to the nanometer scale.

Advanced Materials and Techniques

The use of specialized alloys and corrosion-resistant coatings is becoming more prevalent, extending stencil lifespan and reducing wear over time. Advanced optical lithography techniques, including ultraviolet lithography, are being employed to create more precise patterns. Additionally, automation and smart manufacturing technologies are increasingly used in the design, production, and testing processes to enhance accuracy and reduce errors.

Impact of PCB Stencils on Production Costs

PCB stencils not only enhance production efficiency but also contribute to cost savings. By minimizing excess solder paste and reducing the need for manual rework, stencils help lower material and labor costs. The precise application of solder paste reduces defects, which in turn decreases the amount of scrap and rework required, further reducing production expenses.

Cost Comparison: Stencil Printing vs. Jet-Based Printing

While stencil printing is widely used for its precision and cost-effectiveness in high-volume production, jet-based solder printing offers advantages in terms of speed and flexibility for complex PCB designs. Stencil printing provides consistent results and is highly scalable, making it ideal for standard PCB assemblies. However, jet printing can be more suitable for intricate designs or when rapid prototyping is necessary, despite its higher initial setup costs[6].

PCB Assembly Costs and Optimization Strategies

PCB assembly accounts for a significant portion of the total production cost for electronics products. Factors such as board complexity, component types, and assembly technology influence these costs. To optimize PCB assembly expenses, manufacturers can employ strategies like Design for Manufacturing (DFM), choosing cost-effective assembly technologies, and consolidating components. Additionally, ordering in volume can leverage economies of scale to reduce per-unit costs[3].

The Role of Stencils in SMT Precision and Efficiency

In the rapidly evolving world of electronics manufacturing, Surface Mount Technology (SMT) plays a critical role. One essential element in the SMT process that often goes unnoticed is the stencil. The stencil, though seemingly simple, is a key player in ensuring precision, efficiency, and overall product quality. It provides accurate solder paste deposition, which is crucial for maintaining high-quality standards and reducing defects during the assembly process[4].

Advanced PCB and Stencil Services

Modern PCB services offer integrated solutions that streamline the ordering process and ensure compatibility between PCB and stencil designs. Advanced techniques such as laser direct imaging (LDI) and additive manufacturing are being adapted for PCB fabrication. Stencil services are evolving with innovations like nano-coating and electroforming, which enhance stencil performance and precision[5].

Conclusion

PCB stencils are an essential tool in electronic design and manufacturing, significantly improving the efficiency and accuracy of solder paste application. By selecting the appropriate stencil type and material, manufacturers can optimize production processes, reduce costs, and enhance the quality of their products. As technology continues to advance, PCB stencils will remain a fundamental element in the ever-evolving landscape of electronic product development.

FAQs

1. What is the primary function of an Express PCB SMT Stencil?

An Express PCB SMT Stencil is used to apply solder paste accurately onto the PCB pads, ensuring the correct amount of solder is used for each component. This process is crucial for maintaining precision and consistency in SMT assembly.

2. How do PCB stencils improve production efficiency?

PCB stencils improve production efficiency by automating the solder paste application process, reducing labor costs, and increasing throughput. They enable faster and more consistent paste deposition compared to manual methods, which is particularly beneficial for high-volume production.

3. What materials are commonly used for PCB stencils?

Common materials for PCB stencils include stainless steel, nickel, and polyimide. Stainless steel is the most widely used due to its durability and precision, while nickel offers improved paste release properties.

4. What factors influence the choice of PCB stencil thickness?

The choice of PCB stencil thickness depends on the desired solder joint height and the specific requirements of the PCB design. Thicker stencils result in more solder paste, while thinner stencils produce a smaller volume of paste.

5. Can PCB stencils be reused?

Yes, PCB stencils can be reused multiple times. The lifespan of a stencil depends on factors such as material, usage frequency, and maintenance practices. Regular inspection and cleaning can help extend the stencil's lifespan.

Citations:

[1] https://pcb-copy.com/benefits-of-smt-stencil/

[2] https://highpcb.com/multi-level-stencils/

[3] https://www.pcbelec.com/pcb-assembly-cost-a-comprehensive-guide-for-cost-effective-pcb-manufacturing.html

[4] https://www.oem-pcb.com/news/the-role-of-stencils-in-smt-precision-effici-80830062.html

[5] https://www.linkedin.com/pulse/advanced-pcb-stencils-services-antti-rayming-fxzgc

[6] https://www.escatec.com/blog/pros-and-cons-pcb-stencil-printing-vs-jet-based-solder-printing

[7] https://www.elepcb.com/blog/pcb-stencil-smt-assembly/

[8] https://blueringstencils.com

[9] https://www.technotronix.us/pcbblog/some-of-the-biggest-influences-that-affect-pcb-assembly-cost/

[10] https://www.protoexpress.com/kb/smd-stencils-overview/

[11] https://arshon.com/blog/pcb-stencils-enhancing-the-efficiency-of-solder-paste-application/

[12] https://www.x-pcb.com/cost-analysis-of-stencils-in-smt-manufacturing/

[13] https://www.pcbpower.us/blog/what-are-stencils-and-how-to-use-them-3

[14] https://www.advancedpcb.com/en-us/blog/tags/stencils/

[15] https://www.wevolver.com/article/pcb-stencil

[16] https://www.ipc.org/system/files/technical_resource/E6&S35_03.pdf

[17] https://www.advancedpcb.com/en-us/services/assembly-services/

[18] https://jlcpcb.com/blog/why-pcb-stencils-are-key-to-high-quality-smt-assembly

[19] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[20] https://www.stentech.com