Content Menu

● What Are Customized SMT PCBs?

>> The Evolution of SMT PCBs

● Advantages of Customized SMT PCBs in Cost Reduction

>> 1. Improved Production Efficiency

>> 2. Material Optimization

>> 3. Reduced Defects and Rework

>> 4. Scalability in Production

>> 5. Energy Efficiency

● Key Factors Influencing Cost Reduction with Customized SMT PCBs

>> 1. Design Optimization

>>> Advanced Design Techniques

>> 2. Automation in Assembly

>>> Benefits of Automated Assembly

>> 3. Component Selection

>>> Strategic Component Choices

>> 4. Prototyping and Testing

>>> Advanced Prototyping Techniques

>> 5. Production Volume

● Strategies for Reducing Costs with Customized SMT PCBs

>> 1. Simplify Circuit Design

>>> Design Simplification Techniques

>> 2. Adopt Design-for-Manufacturability (DFM) Principles

>>> Key DFM Considerations

>> 3. Leverage Supplier Expertise

>>> Collaborative Design Process

>> 4. Bulk Ordering

>>> Inventory Management Strategies

>> 5. Use Standardized Components

>>> Benefits of Standardization

● Challenges in Implementing Customized SMT PCBs

>> Overcoming Implementation Challenges

● The Future of Customized SMT PCBs

● Conclusion

● FAQ: Common Questions About Customized SMT PCBs

>> 1. What is the primary advantage of using customized SMT PCBs?

>> 2. How does customization affect prototyping costs?

>> 3. Can customized SMT PCBs handle high-volume production?

>> 4. What factors influence the cost of customized SMT PCBs?

>> 5. How do I choose a supplier for customized SMT PCBs?

In the rapidly evolving electronics industry, customized SMT (Surface Mount Technology) PCBs (Printed Circuit Boards) have emerged as a game-changer for manufacturers seeking to optimize production costs while maintaining high-quality standards. This article delves into how customized SMT PCBs can significantly reduce production costs, exploring their advantages, design considerations, and cost-saving strategies.

What Are Customized SMT PCBs?

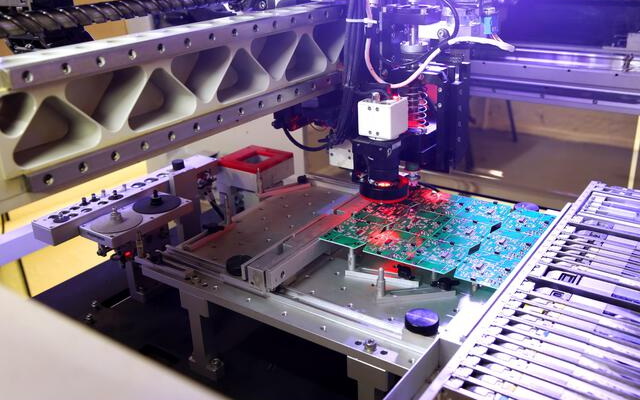

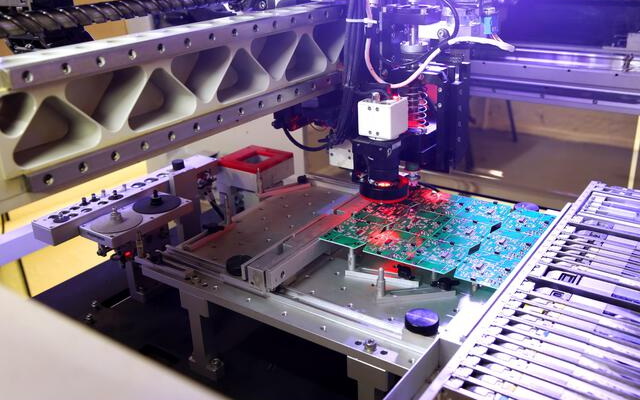

Customized SMT PCBs are tailored circuit boards designed to meet specific requirements of a product or application. Unlike off-the-shelf PCBs, these boards are optimized for component placement, size, layers, and material selection to suit the unique needs of a project. SMT technology involves mounting components directly onto the PCB surface, enabling compact designs and efficient assembly processes.

The Evolution of SMT PCBs

The journey of SMT PCBs began in the 1960s, revolutionizing the electronics industry. Traditional through-hole technology, while reliable, had limitations in terms of board size and component density. SMT addressed these issues, allowing for smaller, more complex designs. Over the years, customized SMT PCBs have become increasingly sophisticated, incorporating advanced materials and design techniques to meet the demands of modern electronics.

Advantages of Customized SMT PCBs in Cost Reduction

1. Improved Production Efficiency

Customized SMT PCBs streamline production by allowing precise component placement using automated pick-and-place machines. This reduces manual labor and minimizes errors during assembly, leading to faster production cycles and lower labor costs.

2. Material Optimization

By tailoring the design, manufacturers can optimize material usage. For instance:

- Selecting cost-effective substrates like FR4 for standard applications.

- Reducing the number of layers or board size to minimize material costs.

- Utilizing advanced materials for specific performance requirements without over-engineering.

3. Reduced Defects and Rework

Customization ensures that the PCB design aligns with the capabilities of SMT assembly machines. Proper pad spacing, clamping edges, and panelization reduce defects such as solder bridging or misalignment, lowering rework and scrap rates.

4. Scalability in Production

Customized SMT PCBs can be designed for scalability, allowing manufacturers to achieve economies of scale. Bulk orders benefit from reduced per-unit costs due to shared tooling and setup expenses.

5. Energy Efficiency

Modern SMT assembly lines are energy-efficient, especially when tailored to specific production needs. This reduces operational costs over time and contributes to a more sustainable manufacturing process.

Key Factors Influencing Cost Reduction with Customized SMT PCBs

1. Design Optimization

Optimizing the PCB layout for SMT assembly ensures efficient use of space and materials. Techniques such as reducing the number of vias and using standard component footprints can lower manufacturing complexity and costs.

Advanced Design Techniques

- Impedance Control: Precise impedance control in high-speed designs reduces signal integrity issues, minimizing the need for costly redesigns.

- Thermal Management: Efficient heat dissipation designs can reduce the need for additional cooling components, lowering overall system costs.

2. Automation in Assembly

SMT assembly can be fully automated with customized designs, eliminating manual intervention and reducing labor costs significantly. Automation also enhances repeatability and consistency in production.

Benefits of Automated Assembly

- Increased Throughput: Automated lines can operate 24/7, significantly increasing production capacity.

- Consistent Quality: Machines maintain consistent quality levels, reducing variability in the final product.

3. Component Selection

Using readily available and cost-effective components reduces sourcing expenses. Customized designs can avoid proprietary or rare components that increase costs.

Strategic Component Choices

- Multi-sourcing: Designing with components available from multiple suppliers ensures supply chain resilience and competitive pricing.

- Package Optimization: Choosing the right component packages can reduce board size and assembly complexity.

4. Prototyping and Testing

Customized designs minimize iterations during prototyping by addressing potential issues upfront. This reduces prototyping expenses and accelerates time-to-market.

Advanced Prototyping Techniques

- 3D Printing: Rapid prototyping of enclosures and mechanical components can speed up the overall product development cycle.

- Virtual Prototyping: Using simulation software to test designs before physical prototyping can identify issues early in the development process.

5. Production Volume

Higher production volumes spread fixed costs like tooling over more units, lowering the cost per PCB. Customization enables manufacturers to plan for both small-batch prototypes and large-scale production efficiently.

Strategies for Reducing Costs with Customized SMT PCBs

1. Simplify Circuit Design

Simplifying circuit layouts by reducing unnecessary complexity helps lower material usage and fabrication time.

Design Simplification Techniques

- Component Integration: Using integrated circuits that combine multiple functions can reduce the overall component count.

- Layer Optimization: Carefully planning layer stack-ups can minimize the number of layers required without compromising performance.

2. Adopt Design-for-Manufacturability (DFM) Principles

DFM principles ensure that the PCB design is optimized for efficient manufacturing processes, reducing errors and delays.

Key DFM Considerations

- Standardized Pad Sizes: Using standard pad sizes simplifies the manufacturing process and reduces the likelihood of assembly issues.

- Adequate Spacing: Ensuring sufficient spacing between components facilitates easier assembly and reduces the risk of shorts.

3. Leverage Supplier Expertise

Working closely with PCB suppliers allows manufacturers to access cost-saving recommendations on materials, finishes, and design adjustments.

Collaborative Design Process

- Early Supplier Involvement: Engaging suppliers early in the design process can lead to valuable insights and cost-saving opportunities.

- Technology Roadmapping: Understanding supplier capabilities and future technologies can inform long-term design strategies.

4. Bulk Ordering

Ordering in bulk reduces per-unit costs due to economies of scale in both fabrication and assembly.

Inventory Management Strategies

- Just-in-Time Manufacturing: Balancing bulk ordering with efficient inventory management to minimize storage costs.

- Blanket Orders: Negotiating long-term agreements with suppliers for consistent pricing and availability.

5. Use Standardized Components

Standard components are easier to source and less expensive than custom or proprietary parts.

Benefits of Standardization

- Reduced Lead Times: Standard components are typically more readily available, reducing production delays.

- Easier Replacements: Standardization simplifies maintenance and repair processes in the field.

Challenges in Implementing Customized SMT PCBs

While customized SMT PCBs offer significant cost advantages, they also present challenges:

- Initial Investment: Higher upfront costs for design customization.

- Complexity in Design: Requires skilled engineers familiar with DFM principles.

- Supplier Dependence: Quality depends on supplier expertise in customization.

Addressing these challenges requires careful planning, collaboration with experienced suppliers, and investment in skilled personnel.

Overcoming Implementation Challenges

- Training and Education: Investing in ongoing training for design teams to stay current with SMT technologies and best practices.

- Building Strong Supplier Relationships: Developing long-term partnerships with reliable PCB manufacturers to ensure consistent quality and support.

- Continuous Improvement: Implementing feedback loops to continuously refine and optimize designs based on production data and field performance.

The Future of Customized SMT PCBs

As technology continues to advance, the potential for cost reduction through customized SMT PCBs is likely to grow. Emerging trends such as:

- Artificial Intelligence in Design: AI-assisted design tools that can optimize PCB layouts for cost and performance.

- Advanced Materials: Development of new substrate materials that offer improved performance at lower costs.

- 3D Printed Electronics: Integration of 3D printing technologies with traditional PCB manufacturing for more complex and cost-effective designs.

These advancements promise to further enhance the cost-saving potential of customized SMT PCBs in the future.

Conclusion

Customized SMT PCBs are a powerful tool for reducing production costs while maintaining high-quality standards in electronics manufacturing. By optimizing design layouts, leveraging automation, and adopting cost-effective materials, manufacturers can achieve significant savings across the production lifecycle. Despite initial challenges, the long-term benefits of customization far outweigh the drawbacks. As technology continues to evolve, the role of customized SMT PCBs in cost reduction is likely to become even more significant, offering manufacturers new opportunities to innovate and compete in the global market.

FAQ: Common Questions About Customized SMT PCBs

1. What is the primary advantage of using customized SMT PCBs?

Customized SMT PCBs enhance production efficiency by tailoring designs to specific requirements, enabling faster assembly processes and reducing material waste.

2. How does customization affect prototyping costs?

Customization minimizes prototyping iterations by addressing potential design flaws upfront, thereby reducing overall prototyping expenses.

3. Can customized SMT PCBs handle high-volume production?

Yes, customized designs can be scaled up efficiently for high-volume production while benefiting from reduced per-unit costs due to economies of scale.

4. What factors influence the cost of customized SMT PCBs?

Key factors include board size, layer count, material selection, design complexity, component sourcing, and production volume.

5. How do I choose a supplier for customized SMT PCBs?

Select a supplier with proven expertise in PCB customization who offers comprehensive services such as design support, prototyping, testing, and scalable manufacturing solutions.