Content Menu

● Understanding Surface Mount Technology

● Evaluate Your Current SMT Processes

● Invest in Training and Development

● Embrace Automation

● Optimize Equipment Maintenance

● Enhance Material Management

● Implement Lean Manufacturing Principles

● Conclusion

● Related Questions

>> 1. What Are the Benefits of Using Surface Mount Technology?

>> 2. How Can Companies Reduce Defects in SMT Processes?

>> 3. What Role Does the Surface Mount Technology Association Play in the Industry?

>> 4. How Can Lean Manufacturing Principles Be Applied to SMT?

>> 5. What Are Current Trends in SMT Automation?

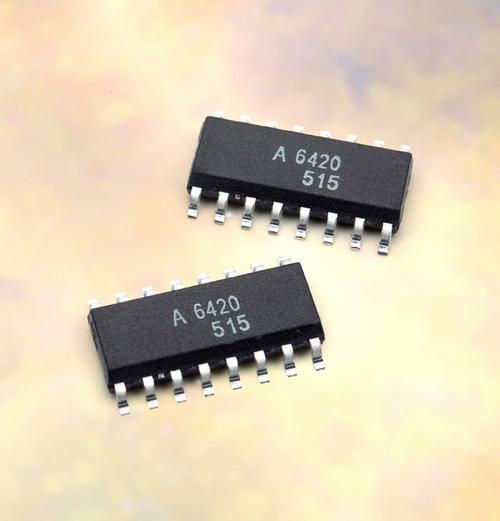

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry. With the increasing demand for compact, efficient, and cost-effective electronic devices, businesses must find ways to optimize their SMT processes to enhance productivity and maintain competitiveness. In this article, we will explore various strategies that organizations can implement to achieve greater efficiency in their SMT operations.

Understanding Surface Mount Technology

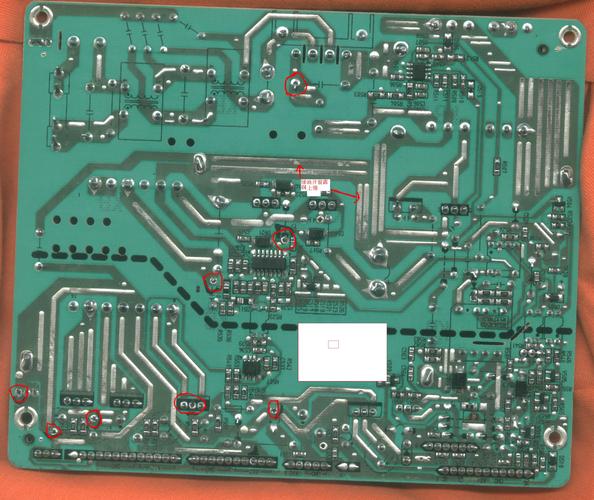

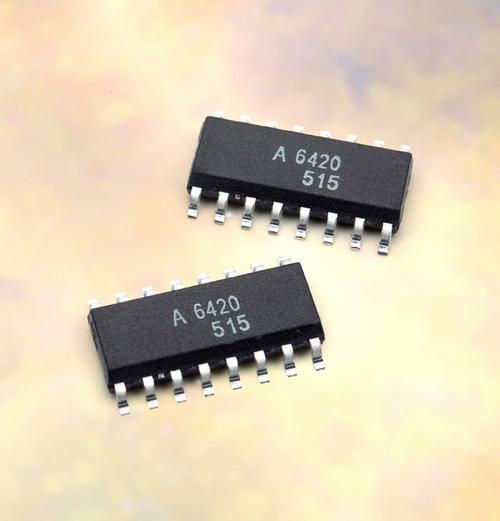

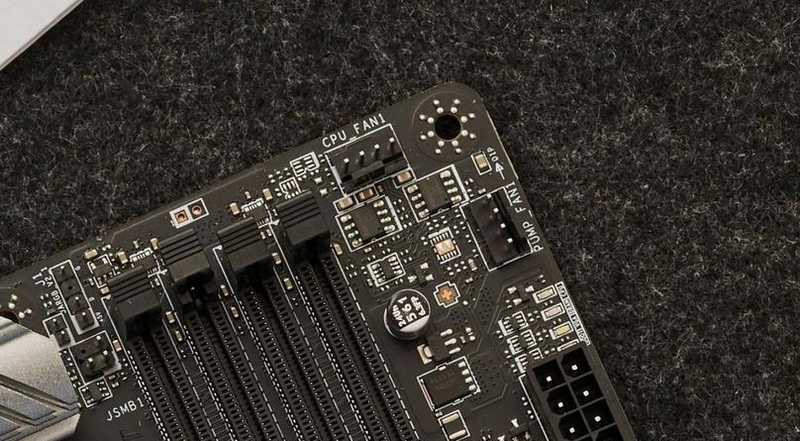

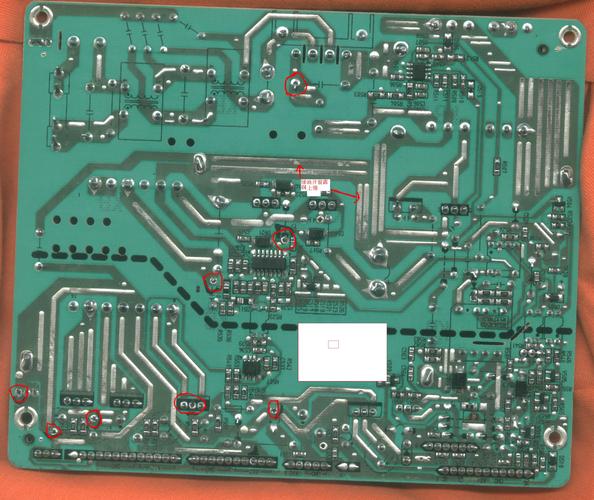

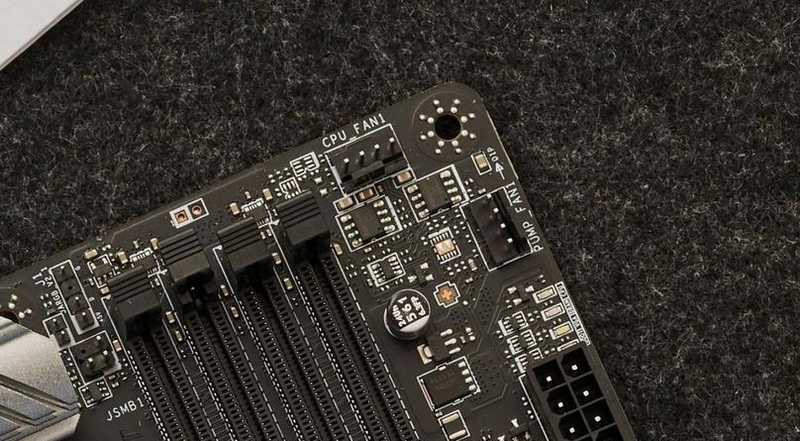

Before delving into optimization strategies, it is essential to understand what Surface Mount Technology entails. SMT is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole technology, SMT allows for a greater component density, enabling manufacturers to produce smaller and lighter devices.

The Surface Mount Technology Association (SMTA) plays a significant role in educating manufacturers about SMT best practices. By leveraging resources from this association, companies can stay updated on the latest innovations and techniques in the electronics manufacturing industry.

Evaluate Your Current SMT Processes

The first step in optimizing SMT processes is to conduct a thorough evaluation of current operations. Identify inefficiencies, bottlenecks, and areas for improvement. This evaluation can involve:

- Analyzing cycle times

- Assessing equipment performance

- Reviewing materials handling and inventory management

- Gathering feedback from operators and engineers

By pinpointing these areas, businesses can prioritize their optimization efforts and focus on implementing changes that will yield the most significant benefits.

Invest in Training and Development

One of the most critical aspects of an efficient SMT process is the skill level of the workforce. Investing in training programs for employees ensures they are familiar with the latest techniques and technologies in SMT. Organizations can:

- Offer workshops and seminars, potentially in partnership with the Surface Mount Technology Association

- Encourage attendance at industry conferences

- Provide hands-on training sessions on new equipment or software

Well-trained personnel are more likely to spot potential issues early, operate machinery effectively, and contribute to a culture of continuous improvement within SMT processes.

Embrace Automation

Automation plays a pivotal role in enhancing the efficiency of SMT processes. Automated equipment can perform tasks more quickly and accurately than manual operation, leading to:

- Reduced labor costs

- Fewer errors and defects in assembly

- Faster production cycles

Businesses should consider investing in automated pick-and-place machines, soldering equipment, and inspection systems. As technology continues to evolve, staying updated with the latest automated solutions is vital for maintaining a competitive edge in electronics manufacturing.

Optimize Equipment Maintenance

Regular maintenance of SMT equipment is essential for minimizing downtime and ensuring optimal performance. Companies should:

- Implement a proactive maintenance schedule

- Utilize predictive maintenance technologies to identify potential issues before they arise

- Train staff on proper equipment handling to avoid unnecessary wear and tear

By prioritizing equipment maintenance, organizations can ensure their machinery operates at peak efficiency, ultimately leading to increased productivity and reduced operational costs in SMT processes.

Enhance Material Management

Efficient material management is crucial in SMT operations. Delays in material supply can halt production and lead to increased costs. To optimize material handling:

- Implement just-in-time inventory practices to reduce excess inventory and associated costs

- Collaborate with reliable suppliers to ensure timely delivery of components

- Leverage software solutions to track inventory levels and streamline ordering processes in SMT operations

Effective material management can lead to reduced lead times, lower production costs, and improved overall efficiency in electronics manufacturing.

Implement Lean Manufacturing Principles

Adopting lean manufacturing principles can lead to significant improvements in SMT processes. Lean methodologies aim to eliminate waste, enhance productivity, and increase profitability. Key tactics include:

- Value stream mapping to identify inefficiencies in the production process

- Reducing setup times to increase machine utilization

- Continuous monitoring and improvement of production metrics

By fostering a lean culture, businesses can optimize their SMT processes and enhance overall operational efficiency.

Conclusion

To remain competitive in the rapidly evolving electronics market, businesses must continuously seek ways to optimize their SMT processes. By evaluating current operations, investing in workforce training, embracing automation, ensuring equipment maintenance, enhancing material management, and implementing lean manufacturing principles, organizations can achieve greater efficiency in their SMT operations. It is essential to leverage resources from organizations like the Surface Mount Technology Association for best practices and industry insights in SMT.

Related Questions

1. What Are the Benefits of Using Surface Mount Technology?

Surface Mount Technology offers several benefits, including reduced PCB space requirements, lower production costs, and enhanced performance of electronic devices due to improved connectivity and reduced noise.

2. How Can Companies Reduce Defects in SMT Processes?

To reduce defects, companies should implement stringent quality control measures, utilize automated inspection systems, and conduct regular training sessions for operators to ensure best practices are followed.

3. What Role Does the Surface Mount Technology Association Play in the Industry?

The Surface Mount Technology Association serves as a vital resource, providing education, networking opportunities, and research initiatives to help businesses improve their SMT practices and stay informed about industry advancements.

4. How Can Lean Manufacturing Principles Be Applied to SMT?

Lean manufacturing principles can be applied to SMT by eliminating waste in the production process, optimizing workflow layouts, and continuously analyzing performance metrics for targeted improvements.

5. What Are Current Trends in SMT Automation?

Current trends in SMT automation include the adoption of AI technologies for predictive analytics, increased use of collaborative robots (cobots) in assembly lines, and advanced automated inspection systems for quality assurance.