Content Menu

● Understanding AOI and Its Importance

● The Role of AOI in SMT Production Lines

● Benefits of Implementing AOI in SMT Production

>> 1. Early Detection of Defects

>> 2. Enhanced Process Control

>> 3. Reduction of Manual Inspection Errors

>> 4. Increased Production Efficiency

>> 5. Cost Savings

● Integrating AOI into Existing SMT Processes

>> 1. Assessing Inspection Needs

>> 2. Choosing the Right Technology

>> 3. Training Personnel

>> 4. Continuous Improvement

● Case Studies Demonstrating Yield Improvement

● Conclusion

● FAQ

>> 1. What types of defects can AOI detect?

>> 2. How does AOI improve production efficiency?

>> 3. Is manual inspection still necessary with AOI?

>> 4. What are the differences between 2D and 3D AOI?

>> 5. How can manufacturers ensure effective integration of AOI?

● Citations:

In the rapidly evolving electronics manufacturing landscape, the demand for high-quality, reliable products has never been greater. As manufacturers strive to meet these demands, Automated Optical Inspection (AOI) systems have emerged as a critical technology in Surface Mount Technology (SMT) production lines. This article explores how AOI products can significantly enhance yield rates in SMT production, discussing their functionality, benefits, and integration into manufacturing processes.

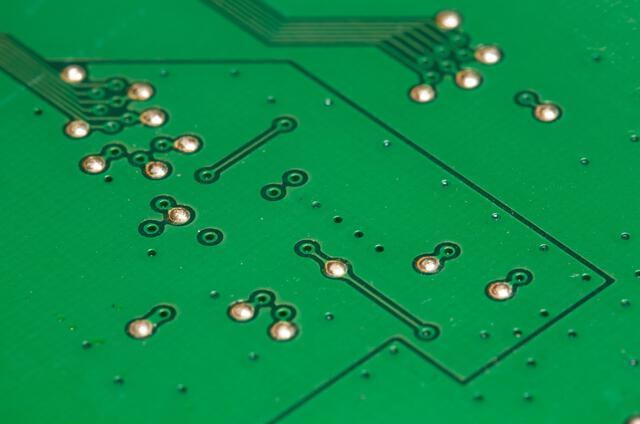

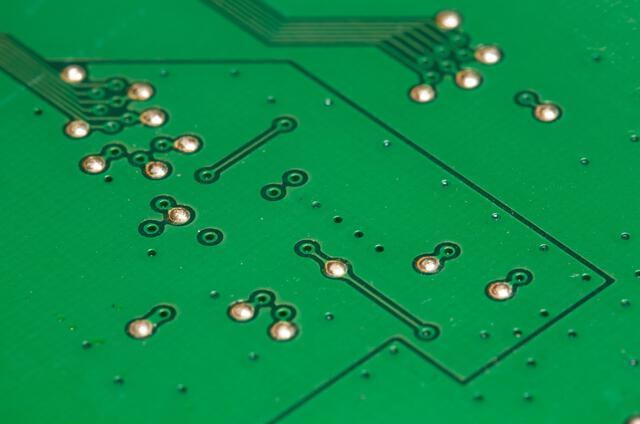

Understanding AOI and Its Importance

Automated Optical Inspection (AOI) is a non-contact inspection method that utilizes high-resolution cameras and sophisticated image processing software to detect defects in printed circuit boards (PCBs) during the manufacturing process. AOI systems can identify various issues, including:

- Missing components

- Misaligned parts

- Soldering defects

- Incorrect component placement

By catching these defects early in the production process, AOI systems help manufacturers avoid costly rework and ensure that only high-quality products reach the market.

The Role of AOI in SMT Production Lines

In SMT production lines, AOI is typically implemented at several key stages:

- Pre-Reflow Inspection: This stage occurs after solder paste printing and before the components are soldered onto the PCB. AOI checks for proper solder paste application and component placement accuracy.

- Post-Reflow Inspection: After the soldering process, AOI inspects the completed assemblies for solder joint quality and component integrity. This step is crucial for identifying defects that may have occurred during the reflow process.

- Continuous Monitoring: Modern AOI systems can monitor production lines in real-time, providing immediate feedback on defect trends and enabling quick corrective actions.

Benefits of Implementing AOI in SMT Production

The integration of AOI into SMT production lines offers numerous advantages that contribute to improved yield rates:

1. Early Detection of Defects

AOI systems provide rapid feedback on potential defects, allowing manufacturers to address issues before they escalate into larger problems. Early detection minimizes the risk of defective products moving further down the production line, reducing overall scrap rates.

2. Enhanced Process Control

By analyzing data collected during inspections, manufacturers can identify patterns and trends in defect occurrences. This information can be used to refine manufacturing processes, leading to continuous improvement and higher yield rates.

3. Reduction of Manual Inspection Errors

Manual inspection methods are prone to human error due to fatigue and subjective judgment. AOI systems provide consistent and objective evaluations of PCBs, significantly reducing the likelihood of missed defects.

4. Increased Production Efficiency

AOI systems operate at high speeds, allowing for the inspection of thousands of components per minute. This rapid inspection capability helps maintain high throughput on SMT production lines without compromising quality.

5. Cost Savings

By reducing defect rates and minimizing rework, AOI systems contribute to significant cost savings in manufacturing operations. The initial investment in AOI technology can be offset by these long-term savings.

Integrating AOI into Existing SMT Processes

To maximize the benefits of AOI technology, manufacturers should consider the following strategies for effective integration:

1. Assessing Inspection Needs

Before implementing an AOI system, manufacturers should evaluate their specific inspection requirements based on product complexity, defect types, and production volume.

2. Choosing the Right Technology

There are various types of AOI systems available—2D and 3D options—each with unique capabilities. Selecting the appropriate system depends on factors such as component density and inspection accuracy requirements.

3. Training Personnel

Proper training for operators and engineers is essential to ensure effective use of AOI systems. Understanding how to interpret inspection data and make necessary adjustments will enhance overall productivity.

4. Continuous Improvement

Manufacturers should regularly review inspection data to identify areas for process improvement. By fostering a culture of continuous improvement, organizations can adapt to changing market demands and maintain high yield rates.

Case Studies Demonstrating Yield Improvement

Numerous case studies illustrate how implementing AOI has led to significant yield improvements in SMT production lines:

- Case Study 1: A manufacturer reported an increase in first-pass yield from 70% to 97% after integrating both pre-reflow and post-reflow AOI inspections into their production line. This improvement was attributed to early detection of component misalignment and soldering defects.

- Case Study 2: Another company reduced its defect rate by over 50% after implementing an inline AOI system that provided real-time feedback on solder paste application quality. This allowed for immediate adjustments during production, enhancing overall quality control.

Conclusion

Automated Optical Inspection (AOI) systems play a pivotal role in enhancing yield rates within SMT production lines by providing early defect detection, improving process control, reducing manual inspection errors, increasing efficiency, and ultimately saving costs. As technology continues to advance, integrating sophisticated AOI solutions will be essential for manufacturers aiming to remain competitive in a fast-paced industry.

FAQ

1. What types of defects can AOI detect?

AOI can identify various defects including missing components, incorrect placements, solder bridging, insufficient solder joints, and more.

2. How does AOI improve production efficiency?

By enabling rapid inspections at multiple stages of production without slowing down the line, AOI enhances throughput while ensuring quality control.

3. Is manual inspection still necessary with AOI?

While AOI significantly reduces reliance on manual inspections, it is often used in conjunction with other testing methods for comprehensive quality assurance.

4. What are the differences between 2D and 3D AOI?

2D AOI captures flat images for surface-level inspections while 3D AOI provides depth information allowing for more detailed analysis of solder joints and component heights.

5. How can manufacturers ensure effective integration of AOI?

Manufacturers should assess their specific needs, choose suitable technology, train personnel adequately, and continuously analyze inspection data for ongoing improvements.

Citations:

[1] https://www.ipc.org/system/files/technical_resource/E10&S04_02.pdf

[2] https://www.zjyingxing.com/info/what-is-the-role-of-aoi-machines-in-the-smt-in-91506284.html

[3] https://www.smtfactory.com/I-C-T-Automated-Optical-Inspection-AOI-to-Improve-SMT-Line-Efficiency-id43297267.html

[4] https://www.neodensmt.com/news/uses-of-aoi-equipment-in-smt-77333603.html

[5] https://www.neodensmt.com/news/what-are-the-problems-of-aoi-detection-in-smt-38253467.html

[6] https://www.grande-pcba.com/the-role-of-aoi-in-smt-assembly/

[7] https://blog.matric.com/smt-production-for-pcbs-matric

[8] https://www.fs-pcba.com/smt-aoi-inspection/

[9] https://www.pcbgogo.com/Article/AOI_in_PCB_and_SMT_Production_Line.html

[10] https://www.raypcb.com/pcb-automated-optical-inspection-aoi/

[11] https://iconnect007.com/index.php/article/44785/improving-smt-yield-with-aoi-and-axi/44788?skin=smt

[12] https://www.neodensmt.com/news/significance-and-advantages-of-smt-aoi-47724829.html

[13] https://www.linkedin.com/pulse/what-aoi-smt-pickandplacemachine

[14] https://iconnect007.com/index.php/article/47786/yield-enhancement-solutions-with-aoi/47789?skin=smt

[15] https://www.x-pcb.com/the-advantages-and-disadvantages-of-aoi-in-smt-patch-processing%EF%BC%881%EF%BC%89/

[16] https://en.wikipedia.org/wiki/Automated_optical_inspection

[17] https://ascinternational.com/process-control/yield-improvement-strategies/

[18] https://asselems.com/en/the-benefits-of-3d-aoi-in-smt-assembly

[19] https://www.rayprasad.com/smt-placing-an-aoi-system-in-the-smt-line

[20] https://vicoimaging.com/aoi-lens-in-ensuring-flawless-smt-and-smd-production/

[21] https://wellmanxray.com/blog/demystifying-aoi-and-axi-in-the-smt-industry/

[22] https://www.electronicsforu.com/market-verticals/industrial/automated-optical-inspection-smt-environment

[23] https://www.linkedin.com/pulse/aoi-pcb-smt-production-line-rigid-flex-pcb-manufactuer-7btac

[24] https://www.pcbcart.com/article/content/aoi-system-for-smt-assembly.html

[25] https://www.7pcb.com/blog/differences-between-aoi-and-spi-in-smt-assembly

[26] https://quality-line.com/smt-quality/

[27] https://www.raypcb.com/pcb-automated-optical-inspection-aoi/

[28] https://versae.com/smt-assembly-faq/

[29] https://visionpro.com/article/what-you-need-to-know-before-buying-your-aoi-solution/

[30] https://www.wevolver.com/article/automated-optical-inspection

[31] https://elsmar.com/elsmarqualityforum/threads/validating-the-aoi-process-automated-optical-inspection.31801/

[32] https://www.youtube.com/watch?v=p1UBwuYL-Fg