Content Menu

● Introduction to SMD LED Mounting Machines

>> Key Features of SMD LED Mounting Machines

● The Role of SMD LEDs in Modern Electronics

>> Advantages of SMD LEDs

● Benefits of Using an SMD LED Mounting Machine

>> 1. Enhanced Production Efficiency

>> 2. Improved Precision and Quality

>> 3. Cost Savings

>> 4. Scalability and Flexibility

>> 5. Support for Miniaturization

● Applications of SMD LED Mounting Machines

>> Automotive Electronics

>> Consumer Electronics

>> Medical Devices

>> Architectural Lighting

● Setting Up an SMD LED Mounting Machine

● Future Trends in SMD LED Mounting Machines

>> Industry 4.0 Integration

>> Sustainability

>> Advanced Material Handling

● Conclusion

● FAQs

>> 1. What industries benefit most from SMD LED mounting machines?

>> 2. How do vision systems improve the performance of these machines?

>> 3. Can these machines handle miniaturized components?

>> 4. Are these machines cost-effective for small-scale production?

>> 5. What maintenance is required for optimal performance?

● Citations:

In the fast-paced world of electronics manufacturing, SMD LED mounting machines have become indispensable tools for improving production efficiency, precision, and scalability. These machines are central to Surface Mount Technology (SMT) assembly lines, enabling manufacturers to meet the growing demand for compact, energy-efficient, and high-quality electronic products. This article explores how SMD LED mounting machines can revolutionize your production line, covering their benefits, applications, and future trends.

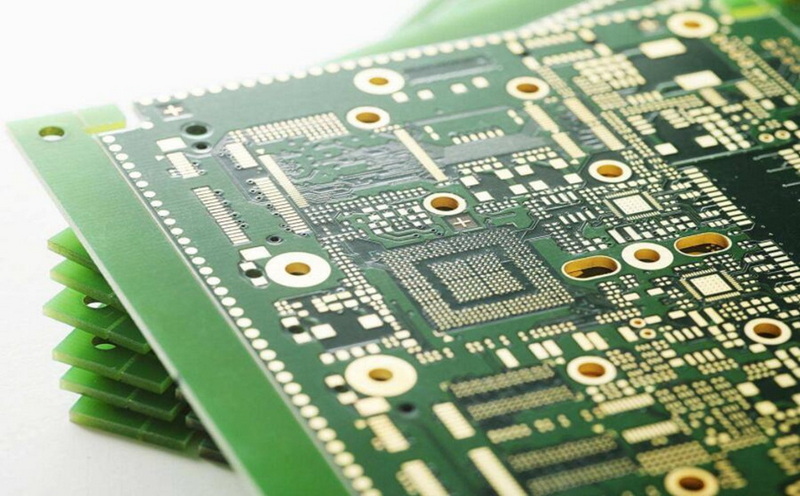

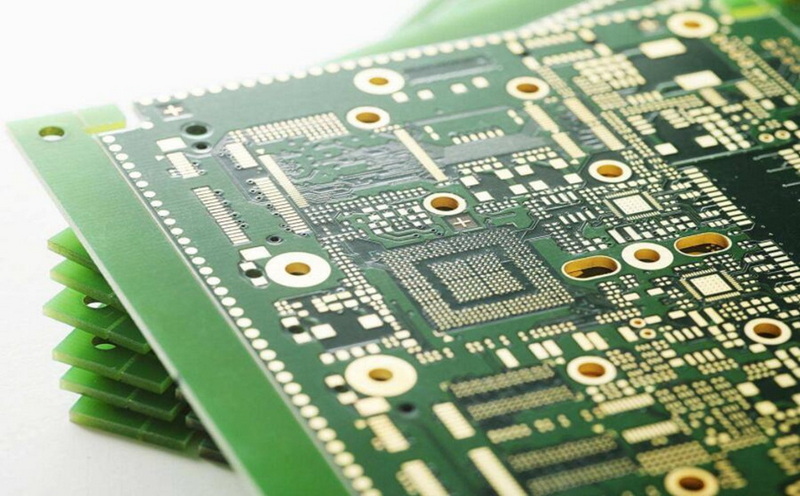

Introduction to SMD LED Mounting Machines

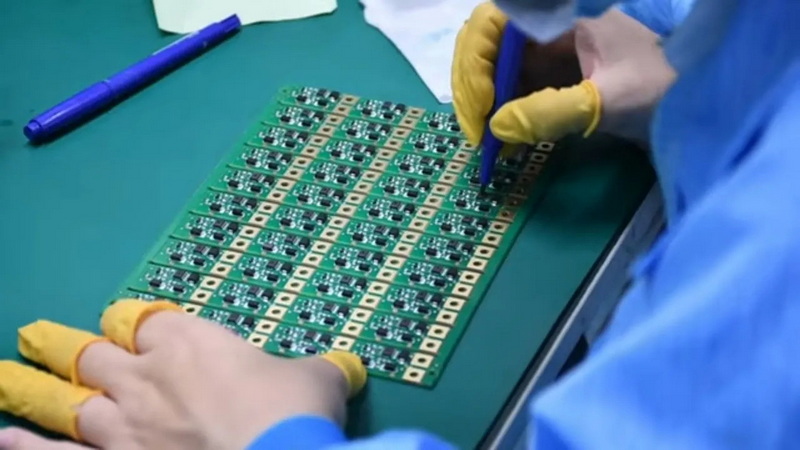

SMD (Surface Mount Device) LED mounting machines are automated systems designed to place SMD components, including LEDs, onto printed circuit boards (PCBs). These machines are vital for industries such as automotive electronics, telecommunications, consumer electronics, and LED lighting. Their ability to handle small components with high precision makes them essential for modern manufacturing processes.

Key Features of SMD LED Mounting Machines

1. High-Speed Placement: Modern machines can place thousands of components per hour, significantly improving production efficiency.

2. Precision Vision Systems: Advanced cameras and algorithms ensure accurate placement of even the smallest components.

3. Versatile Feeder Systems: These systems handle a wide range of component sizes and types.

4. User-Friendly Interfaces: Intuitive software allows operators to program and monitor the machine with ease.

The Role of SMD LEDs in Modern Electronics

Before diving deeper into the benefits of SMD LED mounting machines, it's essential to understand why SMD LEDs are so widely used in modern electronics:

Advantages of SMD LEDs

- Compact Size: Their small size allows for miniaturized designs in devices like smartphones and wearable tech[1][3].

- Energy Efficiency: SMD LEDs consume less power while delivering higher brightness compared to traditional LEDs[1][4].

- Durability: They withstand physical shocks and vibrations better than older LED technologies[1].

- Flexibility in Design: Engineers can create intricate lighting arrays for displays or automotive applications[1][3].

- Cost-Effectiveness: Automated assembly reduces manufacturing costs[3].

These features make SMD LEDs a preferred choice for applications ranging from automotive lighting and medical devices to architectural illumination and consumer electronics.

Benefits of Using an SMD LED Mounting Machine

1. Enhanced Production Efficiency

SMD LED mounting machines automate the placement process, eliminating manual labor and significantly increasing production speed. With the ability to place multiple components simultaneously, these machines ensure faster turnaround times[2][5].

2. Improved Precision and Quality

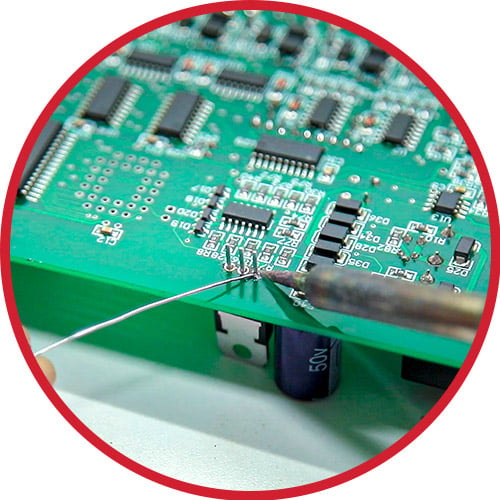

Equipped with advanced vision systems, these machines guarantee accurate placement of components on PCBs. This level of precision reduces defects and ensures consistent product quality[2][5].

3. Cost Savings

- Labor Costs: Automation reduces the need for manual labor.

- Material Waste: Improved accuracy minimizes material waste during assembly.

- Defect Reduction: Fewer defects mean lower rework costs[2][5].

4. Scalability and Flexibility

Modern SMD LED mounting machines can handle a wide variety of PCB sizes and component types, making them suitable for both high-volume production and small-batch manufacturing[2][3].

5. Support for Miniaturization

As electronic devices become smaller and more complex, the ability of these machines to handle tiny components is invaluable. They enable manufacturers to produce compact products without compromising on functionality or quality[2][7].

Applications of SMD LED Mounting Machines

Automotive Electronics

SMD LEDs are widely used in automotive applications such as dashboard displays, headlights, and brake lights due to their reliability and energy efficiency[3][4].

Consumer Electronics

Devices like smartphones, tablets, and smartwatches rely on compact SMD LEDs for backlighting and displays[3].

Medical Devices

SMD LEDs are used in diagnostic equipment and wearable health monitors because of their small size and high performance[3].

Architectural Lighting

The flexibility in design offered by SMD LEDs allows architects to create customized lighting solutions for buildings and outdoor spaces[4].

Setting Up an SMD LED Mounting Machine

Implementing an SMD LED mounting machine requires careful planning:

1. Assess Production Needs: Evaluate your production volume, component types, and PCB sizes.

2. Select the Right Machine: Choose a machine that meets your speed, precision, and scalability requirements.

3. Install and Test Equipment: Ensure proper installation and conduct thorough testing before full-scale production.

4. Train Operators: Provide comprehensive training to ensure efficient operation.

5. Schedule Regular Maintenance: Preventive maintenance is crucial for minimizing downtime.

Future Trends in SMD LED Mounting Machines

Industry 4.0 Integration

The integration of IoT technologies enables real-time monitoring and predictive maintenance, enhancing overall efficiency[4][5].

Sustainability

Eco-friendly practices like lead-free soldering and energy-efficient machinery are becoming standard in SMT production lines[4].

Advanced Material Handling

Innovations in feeder systems allow machines to handle even smaller components with greater accuracy[7].

Conclusion

In conclusion, adopting an SMD LED mounting machine can transform your production line by enhancing efficiency, precision, scalability, and cost-effectiveness. These machines are indispensable for meeting the growing demand for high-quality electronic products while maintaining competitive pricing.

FAQs

1. What industries benefit most from SMD LED mounting machines?

Industries like automotive electronics, telecommunications, consumer electronics, medical devices, and architectural lighting benefit significantly from these machines due to their precision and scalability.

2. How do vision systems improve the performance of these machines?

Vision systems ensure precise placement by analyzing component orientation and detecting defects before they occur.

3. Can these machines handle miniaturized components?

Yes, modern machines are designed to handle extremely small components required for compact electronic devices.

4. Are these machines cost-effective for small-scale production?

While initial investment costs may be high, automation reduces labor costs and defect rates over time, making them cost-effective even for smaller operations.

5. What maintenance is required for optimal performance?

Regular cleaning of nozzles, calibration of vision systems, software updates, and periodic inspections are essential for maintaining machine performance.

Citations:

[1] https://ledsino.com/blog/types-of-smd-led/

[2] https://www.tronstol.com/smt-equipment-led.html

[3] https://jlcpcb.com/blog/smd-revolutionizing-pcb-technology-with-surface-mount-devices

[4] https://www.360iresearch.com/library/intelligence/surface-mount-led

[5] https://www.hwgcsmt.com/info/smt-machines-in-led-lighting-in-102767539.html

[6] https://www.cree-led.com/news/hb-innovation/

[7] https://marktechopto.com/led-component-and-assembly-miniaturization/

[8] https://en.kinglight.com/blog/optoelectronics-industry/smd-led-screen-definition-features-benefits-and-application.html

[9] https://www.knowledge-sourcing.com/report/surface-mount-technology-smt-equipment-market

[10] https://www.linkedin.com/pulse/surface-mount-technology-smt-industry-set-growth-demand-p-virkhe-fd6kf

[11] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[12] https://www.thal-technologies.com/led-smb-smd/

[13] https://www.linsnled.com/cob-led-module-what-is.html

[14] https://www.marketsandmarkets.com/Market-Reports/surface-mount-technology-market-99662691.html

[15] https://www.thebusinessresearchcompany.com/report/surface-mount-technology-smt-equipment-global-market-report

[16] https://www.wicz.com/story/51210332/2024-smd-leds-market-trends-for-industry-growth-2033

[17] https://www.advancedillumination.com/lighting-education/how-machine-vision-shaped-the-general-led-market/

[18] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[19] https://www.consegicbusinessintelligence.com/surface-mount-technology-equipment-market

[20] https://www.pcbonline.com/blog/smd-led.html