Content Menu

● The Evolution of PCB SMT Tools

● Key Benefits of Advanced PCB SMT Tools

>> Increased Production Speed

>> Enhanced Precision and Accuracy

>> Improved Component Density

>> Automated Process Control

● Advanced PCB SMT Tools in Action

>> Solder Paste Printing

>> Pick and Place Machines

>> Reflow Soldering

>> Automated Optical Inspection (AOI)

● Optimizing PCB SMT Processes for Maximum Speed

>> Design for Manufacturability (DFM)

>> Component Selection and Standardization

>> Optimized Production Planning

>> Continuous Process Improvement

● The Future of PCB SMT Manufacturing

>> AI-Powered Optimization

>> Advanced Materials and Components

>> Industry 4.0 Integration

● Conclusion

● FAQ

>> 1. What are the main advantages of using advanced PCB SMT tools?

>> 2. How do pick and place machines contribute to manufacturing speed?

>> 3. What role does Design for Manufacturability (DFM) play in enhancing production speed?

>> 4. How can manufacturers optimize their PCB SMT processes for maximum speed?

>> 5. What future developments can we expect in PCB SMT manufacturing?

● Citations:

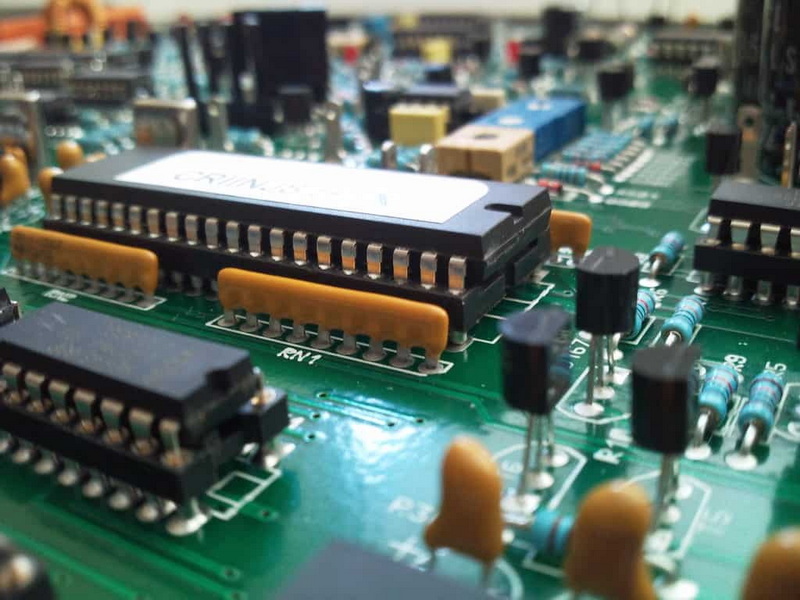

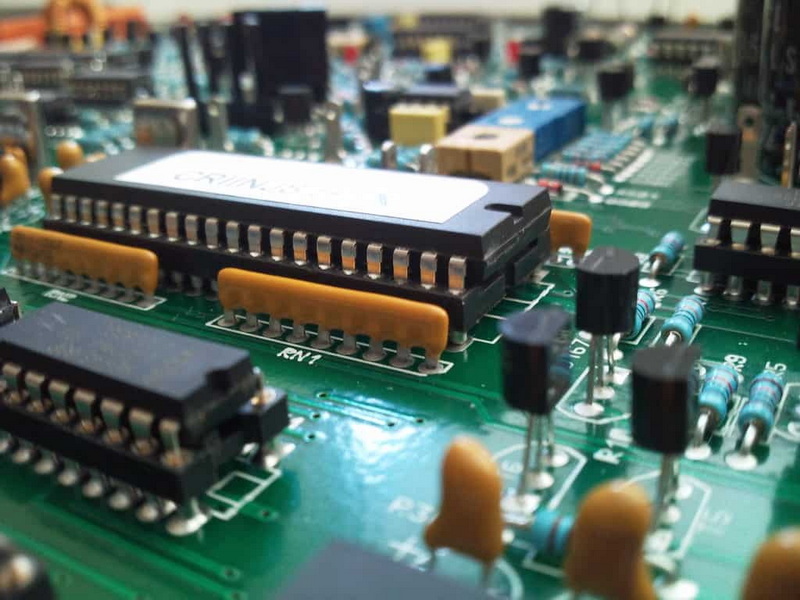

In today's fast-paced electronics industry, manufacturers are constantly seeking ways to improve their production efficiency and reduce time-to-market. One of the most effective methods to achieve this is by leveraging advanced PCB (Printed Circuit Board) SMT (Surface Mount Technology) tools. These cutting-edge herramientas de ensamble pcb smt (PCB SMT assembly tools) have revolutionized the manufacturing process, offering unprecedented speed, precision, and reliability.

The Evolution of PCB SMT Tools

Surface Mount Technology has come a long way since its inception in the 1960s. Initially, SMT was used primarily for military and aerospace applications due to its ability to create smaller, lighter, and more reliable electronic components. As the technology matured, it found its way into consumer electronics, automotive, and industrial applications.

Today, advanced PCB SMT tools are at the forefront of electronic manufacturing, enabling producers to meet the ever-increasing demand for smaller, more complex, and higher-performance electronic devices. These herramientas de ensamble pcb smt have become indispensable in modern electronics production, offering a range of benefits that significantly enhance manufacturing speed and efficiency.

Key Benefits of Advanced PCB SMT Tools

Increased Production Speed

One of the primary advantages of using advanced PCB SMT tools is the dramatic increase in production speed. Modern SMT machines can place components at rates of thousands per hour, far surpassing the capabilities of through-hole mounting techniques[1]. This high-speed placement capability allows manufacturers to produce large volumes of PCBs in a fraction of the time required by traditional methods.

Enhanced Precision and Accuracy

Advanced PCB SMT tools offer unparalleled precision and accuracy in component placement. These machines use sophisticated vision systems and advanced algorithms to ensure that each component is placed exactly where it should be on the PCB. This level of precision not only improves the quality of the final product but also reduces the likelihood of errors and rework, further enhancing production speed.

Improved Component Density

As electronic devices continue to shrink in size while increasing in functionality, the need for higher component density on PCBs has become crucial. Advanced SMT tools enable manufacturers to place components much closer together than ever before, maximizing the use of available board space. This capability allows for the creation of more compact and complex electronic devices without sacrificing performance or reliability.

Automated Process Control

Modern PCB SMT tools incorporate advanced process control features that continuously monitor and adjust various parameters during production. These automated systems can detect and correct issues in real-time, minimizing downtime and ensuring consistent quality across large production runs. By reducing the need for manual intervention, these tools significantly speed up the manufacturing process while maintaining high standards of quality.

Advanced PCB SMT Tools in Action

To fully appreciate the impact of advanced PCB SMT tools on manufacturing speed, let's explore some of the key equipment and processes involved in modern SMT production.

Solder Paste Printing

The first step in the SMT process is applying solder paste to the PCB. Advanced solder paste printers use high-precision stencils and automated squeegee systems to deposit precise amounts of solder paste onto the board's pads. These machines can achieve printing speeds of up to 200 mm per second, with placement accuracy as fine as ±12.5 μm[2]. This level of speed and precision sets the stage for rapid and reliable component placement.

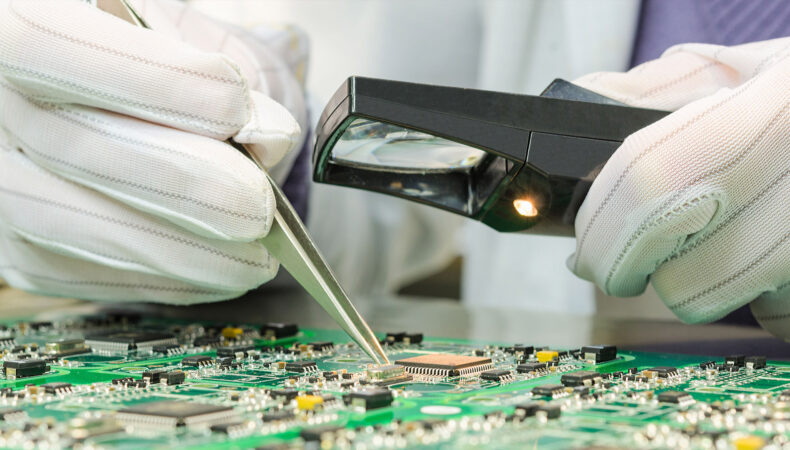

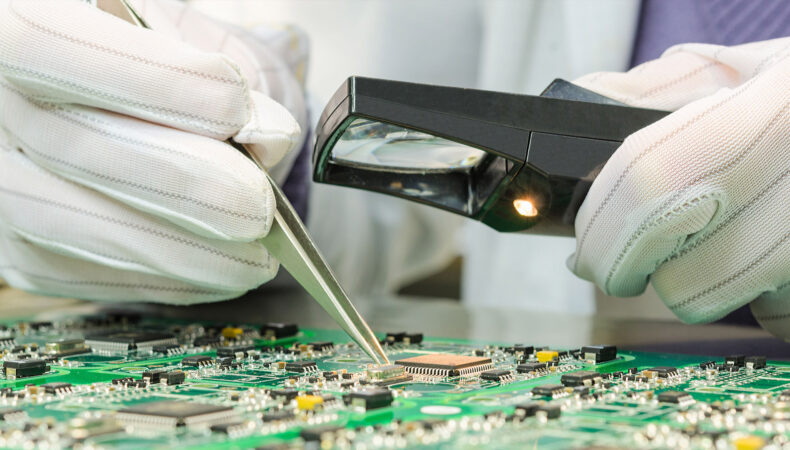

Pick and Place Machines

Perhaps the most critical herramientas de ensamble pcb smt in the SMT process are the pick and place machines. These sophisticated robots use advanced vision systems and high-speed actuators to pick up components from feeders and place them accurately on the PCB. Modern pick and place machines can achieve placement rates of up to 120,000 components per hour, with placement accuracy as fine as ±0.025 mm[3].

Reflow Soldering

After component placement, the PCB undergoes reflow soldering to permanently attach the components to the board. Advanced reflow ovens use precisely controlled temperature profiles to ensure optimal solder joint formation. These ovens can process boards at speeds of up to 1.5 meters per minute, allowing for high-volume production while maintaining consistent quality[4].

Automated Optical Inspection (AOI)

To ensure quality and catch any defects early in the process, advanced AOI systems are employed. These systems use high-resolution cameras and sophisticated image processing algorithms to inspect solder joints, component placement, and overall board quality at speeds of up to 50 cm² per second[5]. By quickly identifying and addressing issues, AOI systems help maintain high production speeds while ensuring product quality.

Optimizing PCB SMT Processes for Maximum Speed

While advanced herramientas de ensamble pcb smt are crucial for enhancing manufacturing speed, their full potential can only be realized through careful optimization of the entire production process. Here are some strategies to maximize the speed and efficiency of your PCB SMT manufacturing:

Design for Manufacturability (DFM)

Implementing DFM principles from the outset of the PCB design process can significantly impact manufacturing speed. By considering factors such as component placement, thermal management, and testability during the design phase, manufacturers can minimize potential issues that could slow down production later on.

Component Selection and Standardization

Choosing components that are compatible with high-speed SMT processes and standardizing component types across different products can greatly enhance manufacturing speed. This approach reduces the need for frequent machine setups and changeovers, allowing for longer, more efficient production runs.

Optimized Production Planning

Careful planning of production schedules, including the sequencing of different board types and batch sizes, can help maximize the utilization of SMT equipment. By minimizing changeover times and balancing workloads across different machines, manufacturers can achieve higher overall production speeds.

Continuous Process Improvement

Implementing a culture of continuous improvement is essential for maintaining and enhancing manufacturing speed over time. This involves regularly analyzing production data, identifying bottlenecks, and implementing solutions to address them. Advanced PCB SMT tools often come equipped with data collection and analysis capabilities that can aid in this process.

The Future of PCB SMT Manufacturing

As technology continues to advance, we can expect to see even more sophisticated herramientas de ensamble pcb smt emerge, further enhancing manufacturing speed and efficiency. Some exciting developments on the horizon include:

AI-Powered Optimization

Artificial Intelligence (AI) and Machine Learning (ML) algorithms are being integrated into SMT equipment to optimize various aspects of the production process automatically. These systems can analyze vast amounts of data in real-time to make intelligent decisions about component placement, process parameters, and maintenance schedules, potentially leading to significant speed improvements.

Advanced Materials and Components

The development of new materials and component types, such as embedded components and 3D-printed electronics, is opening up new possibilities for PCB design and manufacturing. These advancements may lead to even faster and more efficient production processes in the future.

Industry 4.0 Integration

The integration of PCB SMT manufacturing into the broader Industry 4.0 ecosystem promises to bring about new levels of speed and efficiency. By connecting SMT equipment with other factory systems and supply chain partners, manufacturers can achieve unprecedented levels of coordination and optimization across their entire production process.

Conclusion

Advanced PCB SMT tools have revolutionized the electronics manufacturing industry, offering unprecedented speed, precision, and reliability. By leveraging these herramientas de ensamble pcb smt, manufacturers can significantly enhance their production efficiency, reduce time-to-market, and stay competitive in an increasingly demanding market.

To fully realize the benefits of these advanced tools, manufacturers must adopt a holistic approach that encompasses careful design considerations, optimized production planning, and a commitment to continuous improvement. As technology continues to evolve, we can expect to see even more exciting developments in PCB SMT manufacturing, further pushing the boundaries of what's possible in terms of speed and efficiency.

By staying abreast of these advancements and continuously investing in cutting-edge herramientas de ensamble pcb smt, electronics manufacturers can position themselves for success in an ever-changing industry landscape.

FAQ

1. What are the main advantages of using advanced PCB SMT tools?

The main advantages of using advanced PCB SMT tools include increased production speed, enhanced precision and accuracy in component placement, improved component density on PCBs, and automated process control. These benefits lead to faster manufacturing processes, higher quality products, and reduced production costs.

2. How do pick and place machines contribute to manufacturing speed?

Pick and place machines are crucial herramientas de ensamble pcb smt that significantly contribute to manufacturing speed. Modern pick and place machines can achieve placement rates of up to 120,000 components per hour, with placement accuracy as fine as ±0.025 mm. This high-speed, precise placement capability allows for rapid assembly of complex PCBs.

3. What role does Design for Manufacturability (DFM) play in enhancing production speed?

Design for Manufacturability (DFM) plays a crucial role in enhancing production speed by considering factors such as component placement, thermal management, and testability during the PCB design phase. By implementing DFM principles, manufacturers can minimize potential issues that could slow down production later on, leading to smoother and faster manufacturing processes.

4. How can manufacturers optimize their PCB SMT processes for maximum speed?

Manufacturers can optimize their PCB SMT processes for maximum speed by implementing strategies such as Design for Manufacturability, component selection and standardization, optimized production planning, and continuous process improvement. These approaches help minimize setup times, reduce bottlenecks, and ensure efficient utilization of advanced herramientas de ensamble pcb smt.

5. What future developments can we expect in PCB SMT manufacturing?

Future developments in PCB SMT manufacturing are likely to include AI-powered optimization, where artificial intelligence and machine learning algorithms are integrated into SMT equipment to automatically optimize various aspects of the production process. We can also expect advancements in materials and components, such as embedded components and 3D-printed electronics, as well as further integration of PCB SMT manufacturing into the broader Industry 4.0 ecosystem.

Citations:

[1] https://www.technotronix.us/pcbblog/how-to-speed-up-the-pcb-production-time-using-smt-pcbs/

[2] https://www.smtneoden.com/news/how-to-effectively-improve-the-production-efficiency-of-pcb-smt-machine/

[3] https://patents.google.com/patent/CN104244605B/zh

[4] https://www.qualitel.com/qualitel-combines-high-speed-smt-manufacturing-and-superior-quality-with-the-latest-3-d-aoi-for-each-smt-line/

[5] https://www.adoptsmt.com/en/efficiency-enhancement-in-smt-manufacturing/

[6] https://patents.google.com/patent/CN108012450A/zh

[7] https://www.advancedpcb.com/en-us/blog/smt-manufacturing-made-simple-with-advanced-circuits-pcb-design-and-production/

[8] https://blog.matric.com/smt-production-for-pcbs-matric

[9] https://patents.google.com/patent/WO2013166869A1/zh

[10] https://www.thinksemiinfotech.com/pcb-assembly/pcb-smt-assembly-process-helping-you-reduce-production-costs/

[11] https://patents.google.com/patent/CN112040669B/zh