Content Menu

● Introduction

● Understanding SMT Line Machines

>> What is an SMT Line Machine?

>> Key Components of an SMT Line

● Benefits of Wholesale SMT Line Machines

>> 1. Increased Production Speed

>> 2. Enhanced Precision and Quality

>> 3. Cost Efficiency

>> 4. Flexibility and Scalability

>> 5. Integration with Industry 4.0

● How to Implement a Wholesale SMT Line Machine

>> Step 1: Assess Your Needs

>> Step 2: Choose the Right Equipment

>> Step 3: Train Your Workforce

>> Step 4: Monitor and Optimize

● Case Studies: Success Stories of SMT Line Implementation

>> Case Study 1: Electronics Manufacturer A

>> Case Study 2: Automotive Component Supplier B

>> Case Study 3: Consumer Electronics Company C

● Future Trends in SMT Technology

>> 1. Advanced Automation

>> 2. Enhanced Data Analytics

>> 3. Sustainable Manufacturing Practices

>> 4. Customization and Personalization

● Conclusion

● FAQ

>> 1. What is the average cost of a wholesale SMT line machine?

>> 2. How long does it take to set up an SMT line?

>> 3. Can SMT line machines handle different types of components?

>> 4. What maintenance is required for SMT line machines?

>> 5. How can I improve the efficiency of my SMT line?

Introduction

In the fast-paced world of electronics manufacturing, scaling production efficiently is crucial for businesses aiming to meet increasing demand while maintaining quality. One of the most effective ways to achieve this is through the implementation of a wholesale Surface Mount Technology (SMT) line machine. This article explores how these machines can significantly enhance manufacturing capabilities, streamline processes, and ultimately help businesses scale their operations.

Understanding SMT Line Machines

What is an SMT Line Machine?

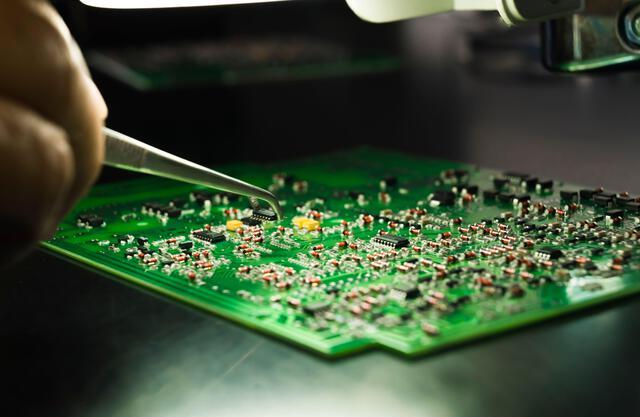

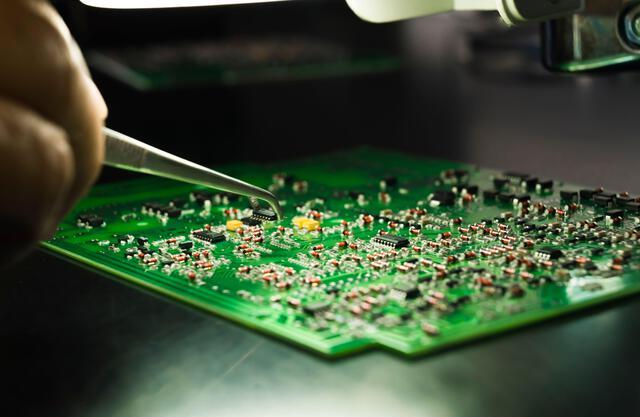

An SMT line machine is a sophisticated assembly system designed for the efficient production of electronic components. It integrates various processes, including solder paste application, component placement, and inspection, into a seamless workflow. The primary goal of an SMT line is to automate the assembly of printed circuit boards (PCBs), which are essential in virtually all electronic devices.

Key Components of an SMT Line

1. Solder Paste Printer: This machine applies solder paste to the PCB, preparing it for component placement.

2. Pick and Place Machine: This crucial component accurately places electronic components onto the PCB.

3. Reflow Oven: After placement, the PCB passes through a reflow oven, where the solder paste is melted to create electrical connections.

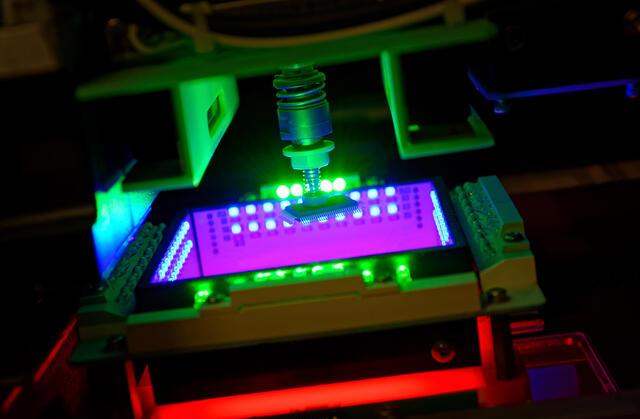

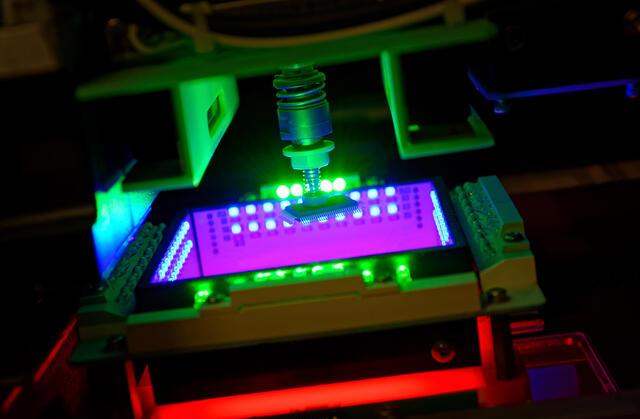

4. Inspection Systems: Automated optical inspection (AOI) systems check for defects in the assembly process, ensuring high quality.

5. Conveyor Systems: These systems transport PCBs between different stages of the assembly process.

Benefits of Wholesale SMT Line Machines

1. Increased Production Speed

One of the most significant advantages of using wholesale SMT line machines is the dramatic increase in production speed. These machines can operate continuously, significantly reducing the time required to assemble PCBs compared to manual processes. For instance, a fully automated SMT line can produce thousands of PCBs per hour, allowing manufacturers to meet high demand without compromising quality.

2. Enhanced Precision and Quality

SMT line machines are designed to operate with high precision. The automated processes minimize human error, ensuring that components are placed accurately and consistently. This precision is crucial for modern electronics, where even minor defects can lead to product failures. Additionally, the integration of inspection systems helps identify and rectify issues early in the production process, further enhancing product quality.

3. Cost Efficiency

While the initial investment in wholesale SMT line machines can be substantial, the long-term cost savings are significant. By automating the assembly process, manufacturers can reduce labor costs and minimize material waste. Furthermore, the increased production speed allows for a quicker return on investment, making it a financially sound decision for many businesses.

4. Flexibility and Scalability

Wholesale SMT line machines offer remarkable flexibility. Manufacturers can easily adjust production volumes by adding or removing machines from the line, allowing them to respond quickly to market changes. This scalability is particularly beneficial for businesses experiencing fluctuating demand, as it enables them to optimize their resources effectively.

5. Integration with Industry 4.0

The rise of Industry 4.0 has transformed manufacturing processes, and SMT line machines are at the forefront of this revolution. These machines can be integrated with smart technologies, such as IoT devices and data analytics, to enhance operational efficiency. For example, real-time monitoring of production data can help identify bottlenecks and optimize workflows, leading to further improvements in efficiency and quality.

How to Implement a Wholesale SMT Line Machine

Step 1: Assess Your Needs

Before investing in an SMT line machine, it is essential to assess your manufacturing needs. Consider factors such as production volume, product complexity, and budget constraints. This assessment will help you choose the right machine configuration for your business.

Step 2: Choose the Right Equipment

Selecting the appropriate SMT line equipment is crucial for maximizing efficiency. Research different manufacturers and models, focusing on features such as speed, precision, and ease of use. It may also be beneficial to consult with industry experts or attend trade shows to gain insights into the latest technologies.

Step 3: Train Your Workforce

While SMT line machines are designed for automation, it is still essential to train your workforce on how to operate and maintain the equipment. Proper training ensures that employees can troubleshoot issues and optimize the production process, leading to better overall performance.

Step 4: Monitor and Optimize

Once your SMT line machine is operational, continuously monitor its performance. Use data analytics to identify areas for improvement and implement changes as needed. Regular maintenance is also crucial to ensure the longevity and efficiency of the equipment.

Case Studies: Success Stories of SMT Line Implementation

Case Study 1: Electronics Manufacturer A

Electronics Manufacturer A faced challenges in meeting the growing demand for their products. By implementing a wholesale SMT line machine, they increased their production capacity by 300% within six months. The automation of their assembly process reduced labor costs by 40% and improved product quality, leading to a significant increase in customer satisfaction.

Case Study 2: Automotive Component Supplier B

Supplier B specialized in automotive electronics but struggled with production delays. After integrating an SMT line machine, they streamlined their operations, reducing assembly time by 50%. The enhanced precision of the machines minimized defects, allowing them to meet stringent automotive industry standards and expand their client base.

Case Study 3: Consumer Electronics Company C

Company C, a consumer electronics manufacturer, sought to innovate their product line while maintaining cost efficiency. By adopting a wholesale SMT line machine, they were able to introduce new products to market 30% faster than before. The flexibility of the SMT line allowed them to quickly adapt to changing consumer preferences, ensuring they remained competitive in a rapidly evolving market.

Future Trends in SMT Technology

1. Advanced Automation

The future of SMT technology lies in further automation. As robotics and AI continue to evolve, we can expect to see even more sophisticated machines capable of handling complex assembly tasks with minimal human intervention.

2. Enhanced Data Analytics

With the integration of Industry 4.0 technologies, data analytics will play a crucial role in optimizing SMT line performance. Manufacturers will be able to leverage real-time data to make informed decisions, improving efficiency and reducing downtime.

3. Sustainable Manufacturing Practices

As sustainability becomes a priority for many industries, SMT manufacturers are exploring eco-friendly practices. This includes reducing energy consumption, minimizing waste, and using sustainable materials in the production process.

4. Customization and Personalization

The demand for customized electronic products is on the rise. SMT line machines will need to adapt to accommodate smaller production runs and personalized products, allowing manufacturers to meet diverse consumer needs.

Conclusion

Wholesale SMT line machines are a game-changer for electronics manufacturers looking to scale their operations. By increasing production speed, enhancing precision, and providing cost efficiencies, these machines enable businesses to meet growing demand while maintaining high-quality standards. As the industry continues to evolve, integrating smart technologies with SMT line machines will further enhance their capabilities, paving the way for a more efficient and responsive manufacturing landscape.

FAQ

1. What is the average cost of a wholesale SMT line machine?

The cost of an SMT line machine can vary significantly based on its features and capabilities, ranging from $500,000 for basic models to over $5 million for fully equipped, high-end systems.

2. How long does it take to set up an SMT line?

The setup time for an SMT line can vary depending on the complexity of the system and the specific requirements of the manufacturer. Generally, it can take anywhere from a few weeks to several months to fully implement and optimize an SMT line.

3. Can SMT line machines handle different types of components?

Yes, modern SMT line machines are designed to handle a wide variety of components, including surface mount devices (SMDs) of various sizes and shapes, making them versatile for different manufacturing needs.

4. What maintenance is required for SMT line machines?

Regular maintenance for SMT line machines includes cleaning, calibration, and inspection of components to ensure optimal performance. It is also essential to follow the manufacturer's guidelines for maintenance schedules.

5. How can I improve the efficiency of my SMT line?

To improve the efficiency of your SMT line, consider implementing real-time monitoring systems, optimizing workflows, and investing in employee training to ensure that your workforce is skilled in operating the equipment effectively.