Content Menu

● Introduction

● Understanding SMT Technology

>> What is SMT?

>> Benefits of SMT in LED Manufacturing

● The Role of a Wholesale SMT LED Production Line

>> Key Components of an SMT LED Production Line

>> Advantages of Wholesale Production Lines

● Enhancing LED Manufacturing with SMT Production Lines

>> Improved Production Speed

>> Consistent Quality Control

>> Flexibility in Production

>> Enhanced Supply Chain Management

● Case Studies: Successful Implementations

>> Company A: Revolutionizing Production

>> Company B: Meeting Market Demands

>> Company C: Quality Assurance

● Future Trends in SMT LED Manufacturing

>> Integration of AI and Machine Learning

>> Sustainable Manufacturing Practices

>> Customization and Personalization

● Detailed Process of SMT LED Manufacturing

>> 1. Solder Paste Application

>> 2. Component Placement

>> 3. Reflow Soldering

>> 4. Inspection and Testing

● The Importance of Training and Skill Development

● The Economic Impact of SMT Production Lines

● Conclusion

● FAQ

>> 1. What is the main advantage of using SMT in LED manufacturing?

>> 2. How does a wholesale SMT production line improve product quality?

>> 3. Can SMT production lines be customized for different LED products?

>> 4. What are the key components of an SMT LED production line?

>> 5. How does automation in SMT production lines benefit manufacturers?

Introduction

In the rapidly evolving world of electronics, the demand for high-quality LED products continues to rise. As manufacturers strive to meet this demand, the implementation of a wholesale Surface Mount Technology (SMT) LED production line has emerged as a transformative solution. This article explores how such production lines can enhance LED manufacturing processes, improve efficiency, and ensure product quality.

Understanding SMT Technology

What is SMT?

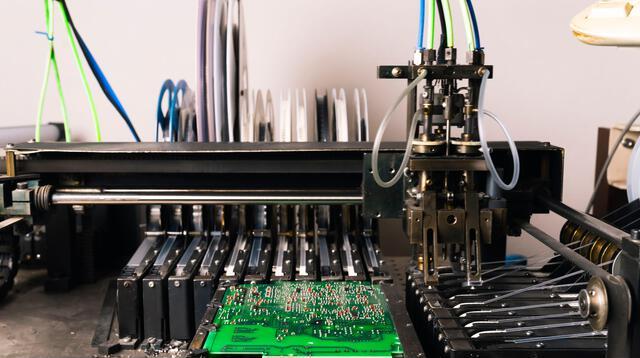

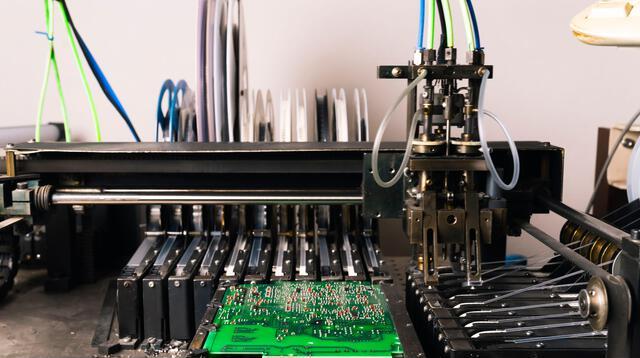

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). This technology has revolutionized the electronics manufacturing industry by allowing for more compact designs, increased production speeds, and improved reliability.

Benefits of SMT in LED Manufacturing

1. Higher Efficiency: SMT allows for faster assembly processes, reducing the time required to produce LED products.

2. Space-Saving Designs: Components can be placed more densely on PCBs, leading to smaller and lighter LED products.

3. Improved Reliability: The soldering process used in SMT creates stronger connections, enhancing the durability of LED products.

The Role of a Wholesale SMT LED Production Line

Key Components of an SMT LED Production Line

A typical SMT LED production line consists of several key components, each playing a crucial role in the manufacturing process:

1. Solder Paste Printer: Applies solder paste to the PCB, preparing it for component placement.

2. Pick-and-Place Machine: Accurately places components onto the PCB.

3. Reflow Oven: Melts the solder paste to create permanent connections between components and the PCB.

4. Inspection Systems: Ensure that all components are correctly placed and soldered.

Advantages of Wholesale Production Lines

1. Cost-Effectiveness: Wholesale production lines can significantly reduce manufacturing costs by optimizing processes and minimizing waste.

2. Scalability: These lines can be easily scaled to meet increasing production demands without compromising quality.

3. Automation: High levels of automation reduce the need for manual labor, decreasing the likelihood of human error and increasing production speed.

Enhancing LED Manufacturing with SMT Production Lines

Improved Production Speed

The integration of advanced machinery in a wholesale SMT LED production line allows for rapid production cycles. Automated systems can operate continuously, significantly increasing output compared to traditional manufacturing methods. For instance, a well-optimized SMT line can produce thousands of LED units per hour, which is a substantial improvement over manual assembly processes.

Consistent Quality Control

Quality control is paramount in LED manufacturing. SMT production lines incorporate sophisticated inspection systems that monitor each stage of the production process. This ensures that any defects are identified and rectified promptly, leading to higher overall product quality. Automated optical inspection (AOI) systems can detect misalignments, soldering defects, and other issues that might compromise the integrity of the LED products.

Flexibility in Production

Wholesale SMT LED production lines can be configured to produce a variety of LED products. This flexibility allows manufacturers to quickly adapt to changing market demands and customer preferences, ensuring they remain competitive. For example, a production line can be easily reconfigured to switch from manufacturing LED bulbs to LED strips, accommodating different product specifications without significant downtime.

Enhanced Supply Chain Management

Implementing a wholesale SMT LED production line also improves supply chain management. With automated inventory tracking and real-time data analytics, manufacturers can better manage their resources, reducing lead times and ensuring that materials are available when needed. This efficiency not only lowers costs but also enhances the ability to respond to market fluctuations.

Case Studies: Successful Implementations

Company A: Revolutionizing Production

Company A implemented a wholesale SMT LED production line and reported a 50% increase in production speed. By automating their processes, they were able to reduce labor costs and improve product consistency. The company also noted a significant decrease in material waste, contributing to a more sustainable manufacturing process.

Company B: Meeting Market Demands

Company B faced challenges in meeting the growing demand for LED products. After adopting an SMT production line, they were able to scale their operations efficiently, resulting in a 30% increase in market share within a year. The flexibility of the SMT line allowed them to introduce new products quickly, keeping pace with consumer trends.

Company C: Quality Assurance

Company C focused on quality assurance by integrating advanced inspection systems into their SMT production line. This investment led to a 40% reduction in product returns due to defects. By ensuring that only the highest quality products reached the market, the company enhanced its reputation and customer satisfaction.

Future Trends in SMT LED Manufacturing

Integration of AI and Machine Learning

The future of SMT LED manufacturing is likely to see increased integration of artificial intelligence (AI) and machine learning technologies. These advancements can optimize production processes by predicting maintenance needs, analyzing production data for continuous improvement, and enhancing quality control measures.

Sustainable Manufacturing Practices

As environmental concerns grow, manufacturers are increasingly focusing on sustainable practices. SMT production lines can be designed to minimize energy consumption and waste, contributing to a more sustainable manufacturing process. This includes using eco-friendly materials and implementing recycling programs for electronic waste.

Customization and Personalization

With the rise of consumer demand for personalized products, SMT production lines will need to adapt to allow for customization. This could involve flexible manufacturing systems that can quickly switch between different product designs and specifications, catering to individual customer needs.

Detailed Process of SMT LED Manufacturing

1. Solder Paste Application

The first step in the SMT process is the application of solder paste to the PCB. This is done using a solder paste printer, which ensures that the right amount of paste is applied to each pad on the board. The precision of this step is crucial, as too much or too little solder can lead to defects in the final product.

2. Component Placement

Once the solder paste is applied, the pick-and-place machine takes over. This machine uses a vacuum system to pick up components from a feeder and place them accurately onto the solder paste. The speed and accuracy of this machine are vital, as they directly affect the overall production speed and quality.

3. Reflow Soldering

After the components are placed, the PCB moves to the reflow oven. Here, the solder paste is heated to a temperature that melts the solder, creating a strong bond between the components and the PCB. The reflow process is carefully controlled to ensure that the solder flows correctly and that components are not damaged by excessive heat.

4. Inspection and Testing

Post-reflow, the PCBs undergo inspection. Automated optical inspection (AOI) systems check for correct component placement, solder quality, and other potential defects. This step is critical for maintaining high product quality and minimizing returns.

The Importance of Training and Skill Development

While automation plays a significant role in SMT LED production lines, the importance of skilled personnel cannot be overlooked. Operators must be trained to understand the machinery, troubleshoot issues, and maintain quality standards. Continuous training programs can help ensure that staff are up-to-date with the latest technologies and best practices in LED manufacturing.

The Economic Impact of SMT Production Lines

The economic benefits of implementing a wholesale SMT LED production line extend beyond immediate cost savings. By increasing production capacity and improving product quality, manufacturers can enhance their market competitiveness. This can lead to increased sales, higher profit margins, and a stronger market presence.

Conclusion

The adoption of a wholesale SMT LED production line represents a significant advancement in LED manufacturing. By enhancing efficiency, ensuring consistent quality, and providing flexibility, these production lines enable manufacturers to meet the increasing demand for high-quality LED products. As the industry continues to evolve, embracing such technologies will be crucial for staying competitive. The integration of AI, sustainable practices, and customization will further shape the future of LED manufacturing, ensuring that companies can adapt to changing market dynamics and consumer preferences.

FAQ

1. What is the main advantage of using SMT in LED manufacturing?

The main advantage of using SMT in LED manufacturing is the increased efficiency and speed of production, allowing for higher output and reduced costs.

2. How does a wholesale SMT production line improve product quality?

A wholesale SMT production line improves product quality through automated inspection systems that monitor each stage of production, ensuring defects are identified and corrected promptly.

3. Can SMT production lines be customized for different LED products?

Yes, SMT production lines can be customized to produce a variety of LED products, providing manufacturers with the flexibility to adapt to changing market demands.

4. What are the key components of an SMT LED production line?

The key components include a solder paste printer, pick-and-place machine, reflow oven, and inspection systems.

5. How does automation in SMT production lines benefit manufacturers?

Automation reduces the need for manual labor, decreases the likelihood of human error, and increases production speed, leading to cost savings and improved efficiency.