Content Menu

● Understanding the LED SMT PCB Unloader

● Key Features of LED SMT PCB Unloaders

>> High Speed and Precision

>> Seamless Integration and Flexibility

>> Automatic PCB Alignment

>> Advanced Safety Features

● Impact on Production Efficiency

>> Increased Throughput and Reduced Downtime

>> Minimized Defect Rate

>> Enhanced Quality Control

● Optimizing the SMT Pipeline

>> Seamless Collaboration with Loaders

>> Minimizing Contamination Risks

>> Ensuring Continuity in Production

● Cost-Effectiveness of LED SMT PCB Unloaders

>> Reduced Labor Costs

>> Lower Defect Rates

>> Increased Production Efficiency

● Choosing the Right LED SMT PCB Unloader

>> PCB Size and Thickness Compatibility

>> Speed and Capacity

>> Integration Capabilities

>> Control System and User Interface

>> Customization Options

● Future Trends in LED SMT PCB Unloaders

>> AI and Machine Learning Integration

>> IoT Connectivity

>> Enhanced Sustainability

>> Greater Versatility

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is the primary function of a LED SMT PCB unloader?

>> 2. How does a LED SMT PCB unloader improve production efficiency?

>> 3. What safety features are typically included in LED SMT PCB unloaders?

>> 4. Can LED SMT PCB unloaders handle different sizes of PCBs?

>> 5. How do LED SMT PCB unloaders integrate with existing assembly lines?

● Citations:

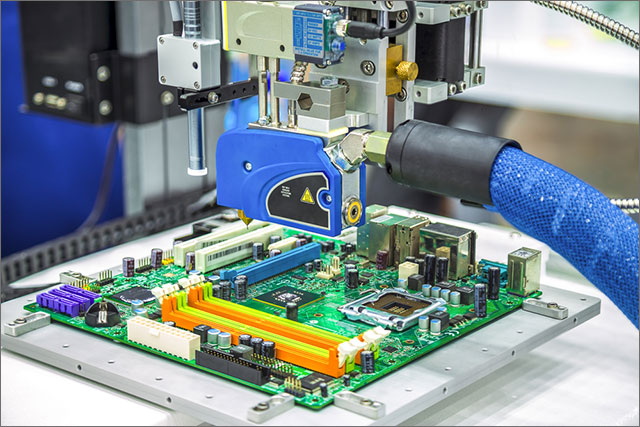

In the fast-paced world of electronics manufacturing, efficiency and precision are paramount. One of the key components that can significantly enhance your PCB assembly line is the LED SMT PCB unloader. This sophisticated piece of equipment plays a crucial role in streamlining the production process, improving quality control, and boosting overall productivity. Let's delve into the ways a LED SMT PCB unloader can revolutionize your PCB assembly line.

Understanding the LED SMT PCB Unloader

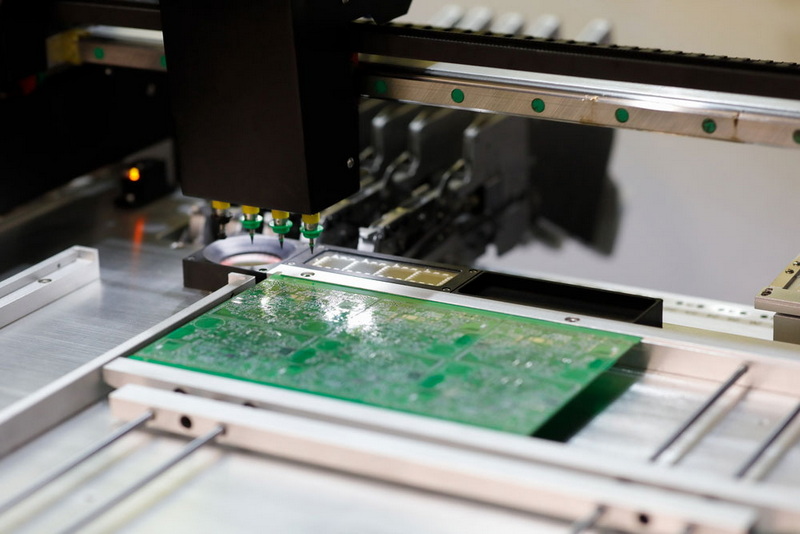

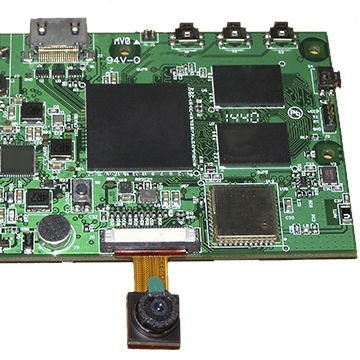

Before we explore its benefits, it's essential to understand what a LED SMT PCB unloader is and how it functions. A LED SMT PCB unloader is a specialized machine designed to automate the process of unloading printed circuit boards (PCBs) from surface-mount technology (SMT) assembly lines[1]. This sophisticated equipment utilizes advanced mechanical systems, including vacuum suction mechanisms and conveyors, to smoothly transport PCBs from the SMT assembly line to subsequent stages of production[1].

Key Features of LED SMT PCB Unloaders

High Speed and Precision

LED SMT PCB unloaders are renowned for their exceptional speed and precision. These machines can handle multiple PCBs simultaneously, offering a substantial increase in productivity[1]. They ensure precise positioning and gentle handling of delicate PCBs, minimizing the risk of damage during the unloading process[1].

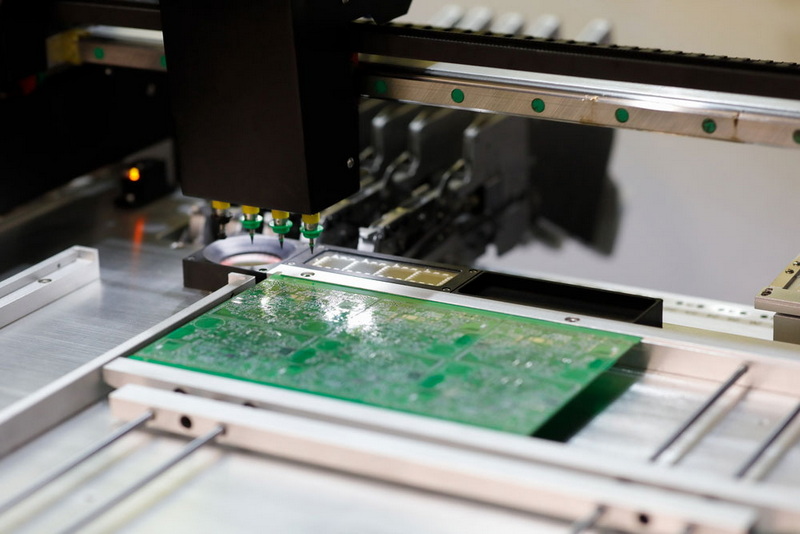

Seamless Integration and Flexibility

One of the standout features of LED SMT PCB unloaders is their ability to seamlessly integrate into existing production lines. They are designed to be compatible with various models of SMT machines, making them a versatile addition to any assembly line[1]. Moreover, these unloaders are highly adaptable, capable of handling PCBs of different sizes and thicknesses, further enhancing the efficiency of the assembly process[1].

Automatic PCB Alignment

LED SMT PCB unloaders come equipped with intelligent alignment systems that automatically detect the orientation of incoming PCBs[1]. This feature eliminates the need for manual adjustment, saving time and reducing human error. The alignment process ensures accurate placement of the PCBs onto the conveyor belt for smooth transportation[1].

Advanced Safety Features

Safety is a top priority in any manufacturing environment, and LED SMT PCB unloaders are designed with this in mind. These machines incorporate advanced safety features such as emergency stop buttons, safety interlocks, and sensors to detect PCB jams or obstructions[1]. These safety measures not only protect the machinery but also ensure a safe working environment for personnel, reducing the risk of accidents and costly machine breakdowns[1].

Impact on Production Efficiency

The integration of a LED SMT PCB unloader into your assembly line can have a profound impact on production efficiency. Let's explore some of the key ways it can improve your manufacturing process.

Increased Throughput and Reduced Downtime

By automating the unloading process, LED SMT PCB unloaders significantly enhance production throughput[1]. They eliminate the need for manual labor in this stage of the assembly process, reducing the chance of human error and improving cycle times[1]. This automation leads to increased efficiency and ultimately boosts overall output.

Minimized Defect Rate

One of the most significant advantages of using a LED SMT PCB unloader is its ability to handle PCBs with extreme precision[1]. This precise handling prevents damage and reduces the number of defects in the production process. By ensuring accurate positioning and gentle handling, these machines contribute to a significant reduction in reject rates, ultimately saving time and associated costs[1].

Enhanced Quality Control

Many LED SMT PCB unloaders come with integrated quality control features such as inspection cameras and optical sensors[1]. These elements enable real-time monitoring of components and PCBs, allowing for immediate identification and rectification of any faults or abnormalities. Consequently, the overall quality of the assembled PCBs improves significantly[1].

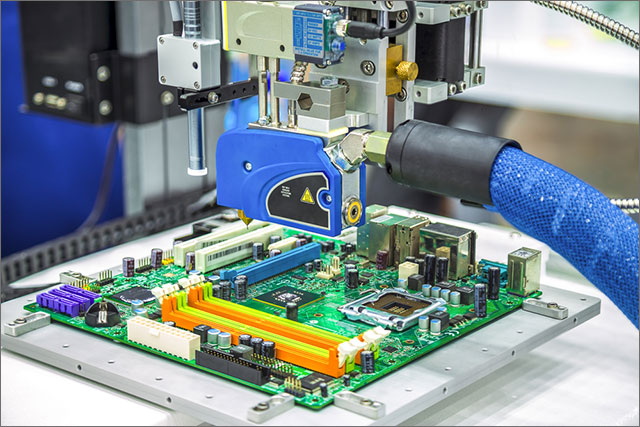

Optimizing the SMT Pipeline

The LED SMT PCB unloader plays a crucial role in optimizing the entire SMT pipeline. It works in tandem with other components of the assembly line to ensure a smooth and efficient production process.

Seamless Collaboration with Loaders

The unloader is designed to work in collaboration with the loader, completing the cycle of automated handling of PCBs from loading to unloading[3]. While the loader ensures that PCBs are accurately placed onto the assembly line, the unloader ensures that finished PCBs are carefully collected and stacked for further processing or packaging[3].

Minimizing Contamination Risks

Just as loaders minimize the risks of contamination during the SMT process, unloaders play a crucial role in ensuring that finished PCBs are not exposed to contaminants[3]. The unloader carefully collects the finished PCBs and holds them in a stack, arranging them in a manner that minimizes the risk of damage or contamination[3].

Ensuring Continuity in Production

The timely removal of finished products from the processing stage ensures the continuity of the process, reducing any unnecessary downtime that could lead to production delays[3]. This continuous flow of PCBs through the assembly line is crucial for maintaining high production rates and meeting demanding production schedules.

Cost-Effectiveness of LED SMT PCB Unloaders

While the initial investment in a LED SMT PCB unloader may seem significant, the long-term cost savings are substantial. Here's how these machines contribute to cost-effectiveness:

Reduced Labor Costs

By automating the unloading process, LED SMT PCB unloaders significantly reduce the labor costs associated with manual handling[3]. This not only leads to direct cost savings but also allows you to reallocate your workforce to more complex tasks that require human expertise.

Lower Defect Rates

As mentioned earlier, the precision handling of PCBs by LED SMT PCB unloaders leads to lower defect rates[1]. This reduction in defects translates to fewer rejected PCBs, less wasted materials, and reduced rework costs, all of which contribute to significant cost savings over time.

Increased Production Efficiency

The speed and efficiency of LED SMT PCB unloaders lead to higher production outputs[1]. This increased productivity allows you to meet higher production demands without necessarily increasing your operational costs, leading to improved profit margins.

Choosing the Right LED SMT PCB Unloader

Selecting the right LED SMT PCB unloader for your assembly line is crucial to maximize its benefits. Here are some factors to consider:

PCB Size and Thickness Compatibility

Ensure that the unloader you choose can handle the range of PCB sizes and thicknesses you work with. Many modern unloaders, like the HY-250ULD, can handle PCBs up to 330mm x 250mm in size[2].

Speed and Capacity

Consider the speed at which the unloader can process PCBs. For instance, some models can unload a PCB in approximately 6 seconds[2]. Also, look at the magazine capacity - some unloaders come with two magazines to ensure uninterrupted operation[2].

Integration Capabilities

Check if the unloader supports standard communication protocols like SMEMA to ensure seamless integration with your existing assembly line equipment[2].

Control System and User Interface

Look for unloaders with user-friendly interfaces, such as LED TFT touch screen control panels, which make operation and monitoring easier[2].

Customization Options

Some manufacturers offer customization options. For example, you might be able to choose between left-to-right or right-to-left transfer directions, or adjust the conveyor speed[2].

Future Trends in LED SMT PCB Unloaders

As technology continues to advance, we can expect to see further improvements in LED SMT PCB unloaders. Some potential future trends include:

AI and Machine Learning Integration

Future unloaders may incorporate AI and machine learning algorithms to optimize their performance, predict maintenance needs, and further reduce defects.

IoT Connectivity

Integration with IoT technology could allow for real-time monitoring and control of unloaders from remote locations, enhancing overall production management.

Enhanced Sustainability

As environmental concerns grow, we may see the development of more energy-efficient unloaders and those designed with recyclable or sustainable materials.

Greater Versatility

Future unloaders may be able to handle an even wider range of PCB sizes and types, including flexible PCBs and those with unconventional shapes.

Conclusion

The LED SMT PCB unloader is an indispensable tool in modern electronics manufacturing, offering numerous benefits such as enhanced productivity, improved quality control, and significant cost savings. By automating the unloading process, these machines not only increase the speed and efficiency of PCB assembly lines but also ensure consistent handling of delicate PCBs, reducing the risk of damage and defects.

Integrating a LED SMT PCB unloader into your assembly line can lead to a substantial increase in throughput, a reduction in downtime, and an overall improvement in product quality. While the initial investment may be significant, the long-term benefits in terms of increased productivity, reduced labor costs, and lower defect rates make it a worthwhile addition to any PCB manufacturing operation.

As technology continues to advance, we can expect to see even more sophisticated LED SMT PCB unloaders in the future, potentially incorporating AI, IoT connectivity, and enhanced sustainability features. These advancements will further streamline the PCB assembly process, helping manufacturers meet the ever-increasing demands of the electronics industry.

In conclusion, if you're looking to optimize your PCB assembly line, improve product quality, and boost your overall manufacturing efficiency, investing in a high-quality LED SMT PCB unloader is a decision that can significantly enhance your production capabilities and give you a competitive edge in the market.

Frequently Asked Questions (FAQ)

1. What is the primary function of a LED SMT PCB unloader?

The primary function of a LED SMT PCB unloader is to automate the process of unloading printed circuit boards (PCBs) from surface-mount technology (SMT) assembly lines[1]. It uses advanced mechanical systems, including vacuum suction mechanisms and conveyors, to smoothly transport PCBs from the assembly line to subsequent stages of production[1].

2. How does a LED SMT PCB unloader improve production efficiency?

A LED SMT PCB unloader improves production efficiency in several ways:

- It increases throughput by handling multiple PCBs simultaneously[1].

- It reduces downtime by eliminating the need for manual unloading[1].

- It minimizes defect rates through precise handling and positioning of PCBs[1].

- It enhances quality control with integrated inspection features[1].

3. What safety features are typically included in LED SMT PCB unloaders?

LED SMT PCB unloaders typically include several safety features such as:

- Emergency stop buttons for immediate halting of operations[1].

- Safety interlocks to prevent accidents during operation[1].

- Sensors to detect PCB jams or obstructions[1].

- Non-abrasive materials to prevent scratching or damaging PCBs during handling[3].

4. Can LED SMT PCB unloaders handle different sizes of PCBs?

Yes, most LED SMT PCB unloaders are designed to be versatile and can handle various PCB sizes and thicknesses[1]. For example, some models can handle PCBs up to 330mm x 250mm in size[2]. However, it's important to check the specifications of the specific model you're considering to ensure it meets your production needs.

5. How do LED SMT PCB unloaders integrate with existing assembly lines?

LED SMT PCB unloaders are designed to seamlessly integrate into existing production lines[1]. They are typically compatible with various models of SMT machines and support standard communication protocols like SMEMA[2]. This allows for easy integration with other equipment in the assembly line, ensuring a smooth and efficient production process.

Citations:

[1] https://www.hct-smt.com/blog/led-smd-pcb-unloader--streamlining-the-assembly-process

[2] https://www.hayawin.com/product-hy-250uld-automatic-unloader.html

[3] https://www.zjyingxing.com/info/what-is-the-role-of-loader-and-unloader-in-the-96545010.html

[4] https://smtmachineline.com/i-c-t-ld-l-pcb-magazine-smt-loader-unloader/

[5] https://www.hct-smt.com/blog/the-ultimate-guide-to-led-smd-pcb-loaders--everything-you-need-to-know

[6] https://www.ascen.ltd/Products/Automatic_SMT_equipment/PCB_loader/91.html

[7] https://www.tronstol.com/smt-equipment-led.html

[8] https://www.smthelp.com/smt-pcb-magazine-unloader-sul-250.html