Content Menu

● Understanding SMT and Its Components

>> Key Components of an SMT Line

● The Role of Feeders in SMT Lines

>> Types of Feeders

● Benefits of High-Quality Feeders

>> 1. Increased Speed

>> 2. Enhanced Accuracy

>> 3. Reduced Downtime

>> 4. Improved Component Handling

>> 5. Flexibility and Compatibility

● The Impact on Overall Productivity

● The Economic Implications of High-Quality Feeders

>> Cost-Benefit Analysis

>> Competitive Advantage

● Maintenance Considerations for Feeders

>> Regular Inspections

>> Cleaning Protocols

>> Training Operators

● Future Trends in SMT Feeding Technology

>> Automation Integration

>> Smart Feeders

>> Eco-Friendly Solutions

● Choosing the Right Feeder for Your SMT Line

>> 1. Compatibility with Existing Equipment

>> 2. Type of Components

>> 3. Speed Requirements

>> 4. Maintenance Needs

>> 5. Budget Constraints

● Conclusion

● FAQ

>> 1. What is an SMT feeder?

>> 2. How does a high-quality feeder improve production speed?

>> 3. What types of feeders are available for SMT lines?

>> 4. Why is accuracy important in SMT assembly?

>> 5. How do I choose the right feeder for my SMT line?

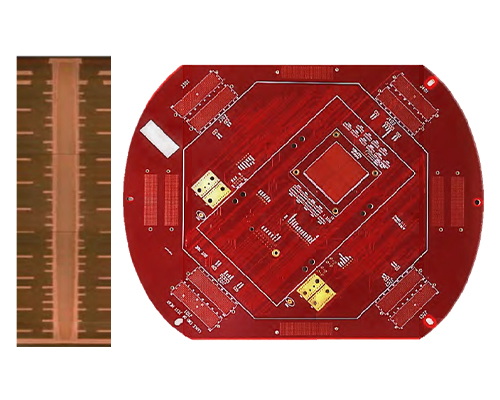

In the rapidly evolving world of electronics manufacturing, Surface Mount Technology (SMT) has become a cornerstone for assembling printed circuit boards (PCBs). With the increasing complexity of electronic devices and the demand for higher production rates, the efficiency of SMT lines is paramount. One critical component that significantly influences this efficiency is the feeder. This article delves into how a high-quality feeder can enhance the performance of your SMT line, exploring various aspects such as speed, accuracy, maintenance, and overall productivity.

Understanding SMT and Its Components

Before discussing feeders, it's essential to understand what SMT entails. SMT is a method that allows electronic components to be mounted directly onto the surface of PCBs. This technology enables smaller devices with more functionalities, which is crucial in today's market where miniaturization is key.

Key Components of an SMT Line

- Pick-and-Place Machines: These machines are responsible for placing components onto PCBs.

- Solder Paste Printers: They apply solder paste onto the PCB pads where components will be placed.

- Reflow Ovens: These are used to melt the solder paste and secure the components to the board.

- Inspectors: Automated Optical Inspection (AOI) systems check for defects post-assembly.

Among these components, feeders play a critical role in ensuring that pick-and-place machines operate efficiently.

The Role of Feeders in SMT Lines

Feeders are devices that supply components to pick-and-place machines in an organized manner. They can hold various types of components, including surface mount devices (SMDs), and are designed to ensure that these components are fed into the machine accurately and at high speeds.

Types of Feeders

1. Mechanical Feeders: These are traditional feeders that use mechanical means to deliver components.

2. Electronic Feeders: These feeders use advanced technology to improve precision and speed.

3. Vacuum Feeders: Utilizing suction, these feeders can handle delicate components without damaging them.

Each type has its advantages and disadvantages, but high-quality electronic or vacuum feeders are often preferred for their efficiency and reliability.

Benefits of High-Quality Feeders

Investing in high-quality feeders can lead to several benefits that improve overall efficiency on your SMT line:

1. Increased Speed

High-quality feeders are engineered for rapid component delivery. They can operate at higher speeds without compromising accuracy, allowing pick-and-place machines to maintain optimal throughput. This increased speed leads to shorter cycle times and higher production rates.

2. Enhanced Accuracy

Accuracy is crucial in SMT assembly. High-quality feeders ensure that components are placed precisely where they need to go. This precision reduces misplacements and defects, leading to fewer reworks and scrap rates.

3. Reduced Downtime

Downtime can significantly impact productivity. High-quality feeders are designed for reliability and ease of maintenance. They often feature quick-change capabilities, allowing operators to switch out component reels swiftly without interrupting the production process.

4. Improved Component Handling

Delicate components require careful handling to avoid damage. High-quality feeders minimize the risk of damaging sensitive parts through gentle feeding mechanisms like vacuum suction or soft delivery systems.

5. Flexibility and Compatibility

Modern high-quality feeders are often compatible with various component types and sizes, providing flexibility in production runs. This adaptability allows manufacturers to respond quickly to changing demands without needing extensive reconfiguration.

The Impact on Overall Productivity

The cumulative effect of these benefits translates into significant productivity gains on your SMT line:

- Higher Output: With increased speed and reduced downtime, manufacturers can produce more units in less time.

- Cost Efficiency: Fewer defects mean lower costs associated with rework and waste.

- Better Quality Products: Improved accuracy leads to higher quality assemblies, enhancing customer satisfaction and reducing warranty claims.

The Economic Implications of High-Quality Feeders

Investing in high-quality feeders not only improves operational efficiency but also has significant economic implications for manufacturers:

Cost-Benefit Analysis

While high-quality feeders may require a more substantial initial investment compared to lower-quality alternatives, the long-term savings typically outweigh these costs. By reducing defect rates and increasing throughput, manufacturers can achieve a quicker return on investment (ROI).

Competitive Advantage

In a market where competition is fierce, having an efficient SMT line can be a distinctive advantage. High-quality feeders contribute to faster production times and superior product quality, allowing companies to meet customer demands more effectively than competitors who may still rely on outdated or less efficient feeding systems.

Maintenance Considerations for Feeders

Maintaining high-quality feeders is essential for sustaining their performance over time:

Regular Inspections

Routine inspections should be conducted to identify any wear or damage that could affect feeder performance. This proactive approach helps prevent unexpected breakdowns during production runs.

Cleaning Protocols

Dust and debris can accumulate in feeders over time, potentially causing jams or misfeeds. Establishing a regular cleaning schedule ensures that feeders operate smoothly and efficiently.

Training Operators

Training operators on proper feeder usage and maintenance practices is crucial. Well-trained personnel can quickly identify issues before they escalate into more significant problems that could disrupt production.

Future Trends in SMT Feeding Technology

As technology continues to advance, several trends are emerging in the realm of SMT feeding systems:

Automation Integration

The integration of automation technologies into feeder systems is becoming increasingly common. Automated feeders can adjust their settings based on real-time data from pick-and-place machines, optimizing performance dynamically.

Smart Feeders

The rise of Industry 4.0 has led to the development of smart feeders equipped with sensors that monitor performance metrics such as speed, accuracy, and component availability in real-time. These innovations enable predictive maintenance strategies that minimize downtime further.

Eco-Friendly Solutions

With growing environmental concerns, manufacturers are also looking at eco-friendly feeder solutions that reduce waste and energy consumption during operation.

Choosing the Right Feeder for Your SMT Line

When selecting a feeder for your SMT line, consider the following factors:

1. Compatibility with Existing Equipment

Ensure that the feeder you choose is compatible with your current pick-and-place machines and other equipment on your line.

2. Type of Components

Consider the types of components you will be using most frequently. Choose a feeder that can handle these efficiently.

3. Speed Requirements

Evaluate your production speed requirements and choose a feeder that meets or exceeds these needs.

4. Maintenance Needs

Select a feeder that requires minimal maintenance while still providing high performance.

5. Budget Constraints

While it's essential to invest in quality equipment, ensure that it fits within your budget without compromising essential features.

Conclusion

In conclusion, a high-quality feeder plays an indispensable role in enhancing efficiency on your SMT line. By increasing speed, improving accuracy, reducing downtime, ensuring better component handling, and providing flexibility, these feeders contribute significantly to overall productivity and cost-effectiveness in electronics manufacturing. As technology continues to advance, investing in top-tier feeding solutions will be vital for staying competitive in this fast-paced industry.

FAQ

1. What is an SMT feeder?

An SMT feeder is a device used in surface mount technology lines to supply electronic components to pick-and-place machines efficiently.

2. How does a high-quality feeder improve production speed?

High-quality feeders are designed for rapid component delivery without sacrificing accuracy, allowing pick-and-place machines to operate at optimal speeds.

3. What types of feeders are available for SMT lines?

There are several types of feeders available including mechanical feeders, electronic feeders, and vacuum feeders, each offering different advantages based on application needs.

4. Why is accuracy important in SMT assembly?

Accuracy is crucial because misplacing components can lead to defects, increased rework costs, and ultimately affect product quality negatively.

5. How do I choose the right feeder for my SMT line?

Consider compatibility with existing equipment, types of components used, required speed, maintenance needs, and budget constraints when selecting a feeder.