Content Menu

● Understanding SMT Assembly

● The Role of High-Precision Equipment

● Process Control Measures

● Advanced Technologies Enhancing Precision

● Common Defects in SMT Assembly

● Benefits of High-Precision SMT Assembly Lines

● Conclusion

● FAQ

>> 1. What are the main advantages of using SMT over THT?

>> 2. How does automated inspection contribute to quality control?

>> 3. What common defects occur during SMT assembly?

>> 4. How important is equipment maintenance in SMT assembly?

>> 5. Can AI improve SMT assembly processes?

● Citations:

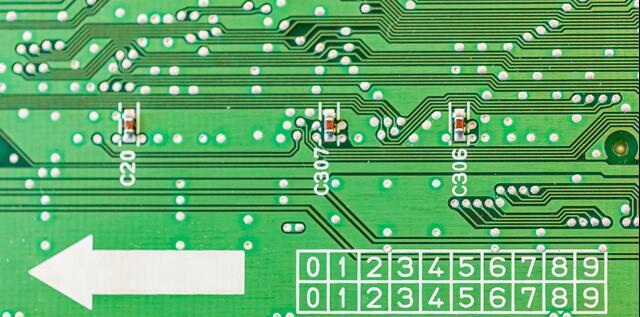

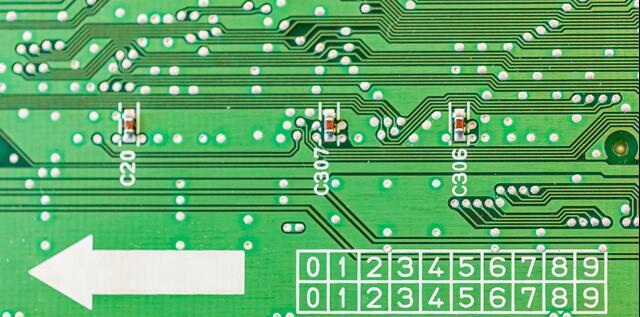

Surface Mount Technology (SMT) has revolutionized the way electronic components are assembled onto printed circuit boards (PCBs). By allowing for the direct mounting of components on the surface of PCBs, SMT has enabled manufacturers to achieve higher density, reduced size, and improved performance in electronic devices. However, the complexity of SMT processes can introduce defects that compromise product quality. This article explores how a high-precision SMT assembly line can significantly reduce defects in PCB manufacturing.

Understanding SMT Assembly

SMT assembly involves several key steps:

- Solder Paste Printing: Solder paste is applied to the PCB pads using a stencil printer.

- Component Placement: Automated pick-and-place machines position the components onto the solder paste.

- Reflow Soldering: The PCB is heated in a reflow oven, where the solder paste melts to create electrical connections.

- Inspection: Automated Optical Inspection (AOI) systems check for defects after soldering.

Each of these steps is critical to ensuring high-quality assemblies. Defects can arise at any stage, making precision in each process essential.

The Role of High-Precision Equipment

High-precision SMT assembly lines utilize advanced machinery and technologies that enhance accuracy and consistency throughout the manufacturing process. Key components include:

- Stencil Printers: These machines apply solder paste with high precision, ensuring even coverage and correct thickness. Variations in solder paste application can lead to defects such as insufficient solder or bridging.

- Pick-and-Place Machines: Equipped with high-resolution vision systems, these machines accurately position components on the PCB. Any misalignment can result in poor connections or component failure.

- Reflow Ovens: Advanced reflow ovens maintain precise temperature profiles to ensure optimal soldering conditions. Inconsistent heating can cause cold solder joints or overheating, leading to component damage.

- Automated Inspection Systems: AOI systems inspect PCBs for defects post-soldering, identifying issues such as misplaced components or insufficient solder before they reach customers.

Process Control Measures

Implementing rigorous process control measures is vital for minimizing defects in SMT assembly. These measures include:

1. Design for Manufacturability (DFM): Early collaboration with design engineers ensures that PCB layouts are optimized for SMT processes, reducing potential defects related to component placement and soldering.

2. Statistical Process Control (SPC): Utilizing SPC techniques allows manufacturers to monitor critical parameters during production. Control charts help identify trends and variations that could lead to defects.

3. Error-Proofing Techniques (Poka-Yoke): Incorporating error-proofing mechanisms, such as component verification through barcode scanning, prevents common assembly mistakes.

4. Regular Maintenance and Calibration: Ensuring that all equipment is regularly maintained and calibrated helps maintain precision in every step of the assembly process.

Advanced Technologies Enhancing Precision

The integration of advanced technologies into SMT assembly lines further enhances defect reduction capabilities:

- 3D Solder Paste Inspection (SPI): This technology measures the volume and alignment of solder paste before component placement, allowing for early detection of potential issues.

- Artificial Intelligence (AI) and Machine Learning: These technologies analyze historical data to predict potential defects and optimize process parameters in real-time.

- Industry 4.0 Integration: Smart factories leverage IoT devices for real-time monitoring and predictive maintenance, enhancing overall efficiency and reducing downtime.

Common Defects in SMT Assembly

Despite advancements in technology, certain defects remain prevalent in SMT assembly processes:

- Solder Bridging: Occurs when excess solder creates unintended connections between pads.

- Tombstoning: A phenomenon where one end of a component lifts off the PCB during reflow due to uneven heating or improper component placement.

- Cold Solder Joints: Result from insufficient heat during the reflow process, leading to weak electrical connections.

- Insufficient Solder Fillets: Occur when there is not enough solder on a joint, compromising electrical conductivity.

To combat these issues, manufacturers must implement strict quality control measures at each stage of production.

Benefits of High-Precision SMT Assembly Lines

Investing in high-precision SMT assembly lines offers numerous advantages:

- Reduced Defect Rates: Precision machinery minimizes human error and ensures consistent quality across production runs.

- Improved Efficiency: Automated processes speed up production times while maintaining high standards of quality control.

- Cost Savings: Lower defect rates translate into reduced rework costs and increased customer satisfaction due to higher-quality products.

- Enhanced Flexibility: High-precision lines can adapt to various component types and sizes, accommodating diverse product requirements without significant downtime.

Conclusion

High-precision SMT assembly lines play a crucial role in reducing defects in PCB manufacturing. By leveraging advanced technologies, rigorous process control measures, and automated inspection systems, manufacturers can enhance product quality while improving efficiency. As electronic devices continue to evolve towards greater complexity and miniaturization, maintaining precision in SMT assembly will be essential for meeting industry demands and ensuring customer satisfaction.

FAQ

1. What are the main advantages of using SMT over THT?

SMT allows for higher component density, smaller size, and reduced weight compared to Through-Hole Technology (THT). It also enables automated processes that improve production efficiency.

2. How does automated inspection contribute to quality control?

Automated Optical Inspection (AOI) systems detect defects such as misaligned components or insufficient solder joints after reflow soldering, ensuring that only high-quality products proceed to customers.

3. What common defects occur during SMT assembly?

Common defects include solder bridging, tombstoning, cold solder joints, and insufficient solder fillets. Each defect can significantly impact product performance if not addressed promptly.

4. How important is equipment maintenance in SMT assembly?

Regular maintenance and calibration of equipment are crucial for maintaining precision and preventing defects during the assembly process.

5. Can AI improve SMT assembly processes?

Yes, AI can analyze data from previous production runs to predict potential defects and optimize process parameters in real-time, enhancing overall efficiency and quality control.

Citations:

[1] https://www.raypcb.com/effective-measures-to-improve-smt-assembly-quality/

[2] https://www.pcbasic.com/blog/smt_production_line.html

[3] https://www.ednasia.com/top-12-incredible-techniques-to-control-the-quality-of-pcb-smt-assembly/

[4] https://www.allsmt.com/SMT-line-concept-assembly-manufacturing-production-Assembly

[5] https://www.pcbx.com/article/20-Common-Q-A-About-SMT-Assembly

[6] https://camptechii.com/resources/frequently-asked-questions/

[7] https://blog.matric.com/smt-production-for-pcbs-matric

[8] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[9] https://rework.co.uk/blog/how-to-achieve-high-precision-in-surface-mount-assemblies/

[10] https://www.mtek.co.uk/frequently-asked-questions-smt-assembly

[11] https://jlcpcb.com/help/article/pcb-assembly-faqs

[12] https://hilelectronic.com/smt-assembly/

[13] https://www.pcbasic.com/blog/smt_machines.html

[14] https://geospacemfg.com/blog/smt-assembly-technology/

[15] https://www.pcbelec.com/pcb_assembly_defects.html

[16] https://www.zetwerk.com/resources/knowledge-base/electronics-manufacturing-services-ems/smt-pcb-boards-high-performance-solutions-for-modern-electronics/

[17] https://www.pcbnet.com/precision-pcb-assembly/

[18] https://jhdpcb.com/blog/efficient-smt-assembly/

[19] https://www.ourpcb.com/smt-line.html

[20] https://www.creativehitech.com/blog/precision-and-efficiency-the-role-of-autocalibration-in-surface-mount-technology/

[21] https://www.pcbcart.com/article/content/smt-process-to-cost-reduction.html

[22] https://www.pcbcart.com/article/content/process-control-in-smt-assembly.html

[23] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[24] https://www.pcbjhy.com/blog/pros-and-cons-of-smt-pcb-assembly/

[25] https://resources.altium.com/p/common-pcb-assembly-defects-you-should-know

[26] https://www.pcbcart.com/article/content/PCB-design-elements-effect-smt-mfg.html

[27] https://www.nextpcb.com/tech-center/smt-assembly-questions-and-answers

[28] https://www.ipcb.com/pcba-tech/8004.html

[29] https://www.venture-mfg.com/smt-manufacturing/

[30] https://www.pcbcart.com/article/content/qa-about-smt-assembly.html

[31] https://www.technotronix.us/faqs.html

[32] https://www.pcbonline.com/blog/pcb-assembly-services.html

[33] https://levisonenterprises.com/your-surface-mount-technology-questions-answered/

[34] https://versae.com/smt-assembly-faq/

[35] https://www.linkedin.com/pulse/10-common-questions-printed-circuit-boards-assembly-abby-hao-ii1ac

[36] https://global.yamaha-motor.com/business/smt/faq/

[37] https://www.reddit.com/r/PrintedCircuitBoard/comments/e9z5op/common_pcb_questions/

[38] https://www.viasion.com/blog/smt-assembly-introduction-applications-steps-common-errors/

[39] https://www.ipc.org/system/files/technical_resource/E40&S06_01%20-%20Greg%20Smith.pdf