Content Menu

● Understanding SMT Components Counting Machines

>> Types of Counting Technologies

● Importance of Accuracy in SMT Components Counting

● Factors Affecting Accuracy

>> Component Characteristics

>> Machine Calibration

>> Environmental Conditions

>> Operator Training

● Best Practices for Ensuring Accuracy

>> Regular Maintenance

>> Choosing the Right Technology

>> Implementing Quality Control Measures

>> Utilizing Software Integration

>> Training Personnel

● Challenges in Achieving High Accuracy

>> Complex Component Designs

>> High-Speed Production Lines

>> Cost Constraints

● Future Trends in SMT Components Counting Technology

>> Artificial Intelligence Integration

>> Enhanced Automation

>> Data Analytics Utilization

● Conclusion

● FAQ

>> 1. What types of technologies are used in SMT components counting machines?

>> 2. How does inaccurate component counting affect manufacturing?

>> 3. What factors influence the accuracy of SMT components counting machines?

>> 4. How often should SMT components counting machines be calibrated?

>> 5. What future trends should we expect in SMT component counting technology?

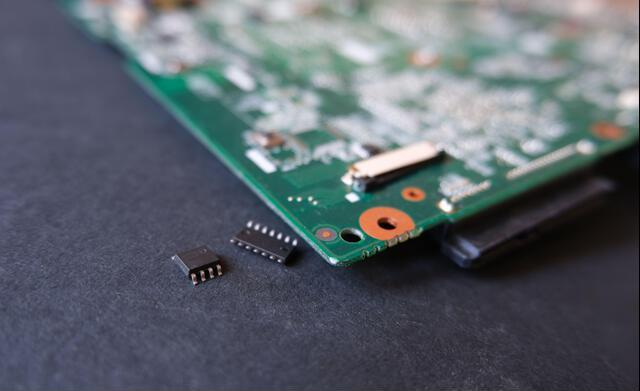

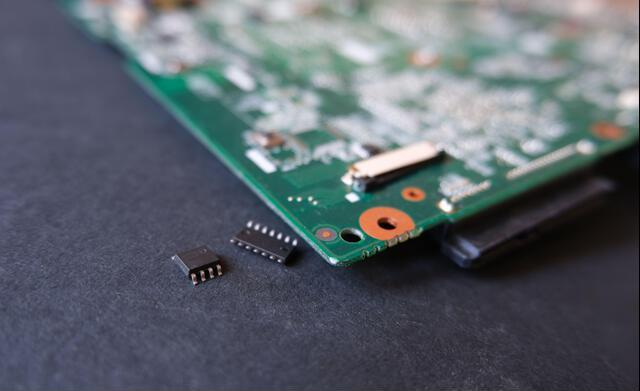

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, enabling the production of compact and efficient devices. A critical aspect of SMT is the accurate counting of components, which is vital for inventory management, production planning, and quality control. This article delves into the accuracy of SMT components counting machines, exploring their technology, benefits, limitations, and best practices for ensuring precision.

Understanding SMT Components Counting Machines

SMT components counting machines are specialized devices designed to count electronic components used in surface mount assembly processes. These machines utilize various technologies, including optical recognition, weight measurement, and advanced algorithms to ensure accurate counts.

Types of Counting Technologies

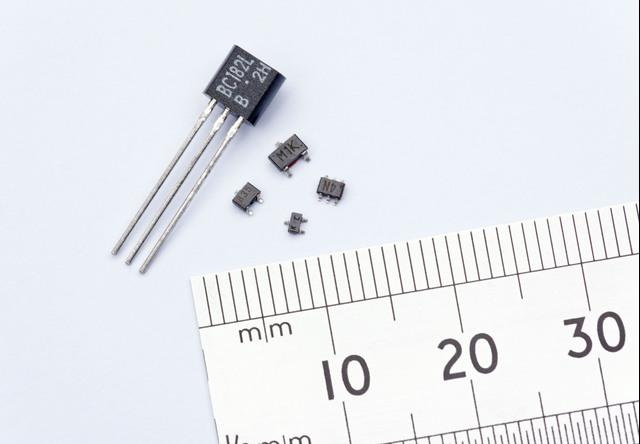

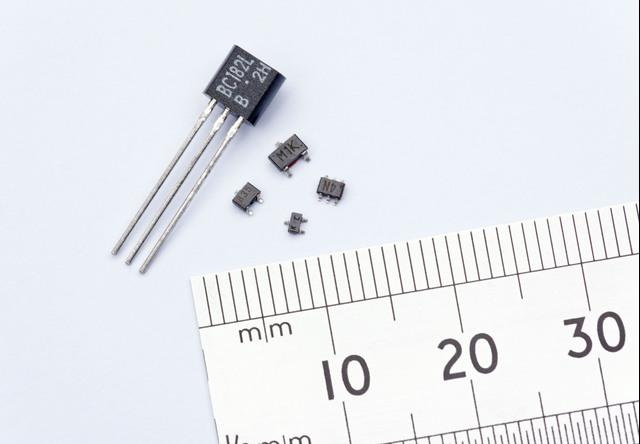

1. Optical Recognition: This method employs cameras and image processing algorithms to identify and count components based on their physical characteristics. Optical counting is highly effective for standard components but may struggle with irregular shapes or transparent materials.

2. Weight Measurement: By measuring the total weight of a batch of components and knowing the average weight of individual items, these machines can provide an estimate of the count. This method is less accurate for small batches or when component weights vary significantly.

3. Laser Scanning: Laser-based systems can measure dimensions and count components by detecting their size and shape. This technology offers high accuracy but may be more expensive than other methods.

4. Mechanical Counting: Some machines use mechanical systems to physically sort and count components as they pass through a conveyor system. While reliable, this method can be slower and less flexible than optical or laser systems.

Importance of Accuracy in SMT Components Counting

Accuracy in counting SMT components is crucial for several reasons:

- Inventory Management: Accurate counts help maintain optimal inventory levels, preventing shortages or excess stock that can lead to increased costs.

- Production Efficiency: Knowing the exact number of components allows manufacturers to plan production schedules effectively, reducing downtime and improving throughput.

- Quality Control: Accurate counting minimizes the risk of errors during assembly, which can lead to defects in the final product.

- Cost Reduction: By ensuring that the right number of components are available at all times, manufacturers can reduce waste and lower overall production costs.

Factors Affecting Accuracy

Several factors can influence the accuracy of SMT components counting machines:

Component Characteristics

- Shape and Size: Irregularly shaped or very small components may be difficult for some counting technologies to detect accurately.

- Material Transparency: Transparent materials can pose challenges for optical recognition systems, leading to potential undercounts.

- Batch Variability: Variations in component size or weight within a batch can affect the accuracy of weight-based counting methods.

Machine Calibration

Regular calibration is essential for maintaining accuracy. Machines must be calibrated according to manufacturer specifications to ensure they provide precise counts over time.

Environmental Conditions

Factors such as lighting conditions, dust, and temperature can impact the performance of optical systems. Maintaining a clean and controlled environment can help mitigate these issues.

Operator Training

Skilled operators who understand how to use counting machines effectively can significantly enhance accuracy. Proper training ensures that operators are aware of machine limitations and best practices for achieving precise counts.

Best Practices for Ensuring Accuracy

To maximize the accuracy of SMT components counting machines, manufacturers should consider implementing the following best practices:

Regular Maintenance

Routine maintenance checks are vital for ensuring that machines operate correctly. This includes cleaning sensors, checking calibration settings, and replacing worn parts as needed.

Choosing the Right Technology

Selecting a counting machine that aligns with specific component types and production needs is crucial. For example, if dealing primarily with small or irregularly shaped components, an optical system with advanced image processing capabilities may be ideal.

Implementing Quality Control Measures

Incorporating quality control procedures into the counting process can help identify discrepancies early. This could involve random sampling or cross-checking counts against inventory records periodically.

Utilizing Software Integration

Integrating counting machines with inventory management software can streamline operations and enhance accuracy. Automated data transfer reduces human error associated with manual entry.

Training Personnel

Investing in training programs for operators ensures they are well-equipped to handle machinery effectively. Knowledgeable staff can troubleshoot issues quickly and maintain high standards of accuracy throughout the counting process.

Challenges in Achieving High Accuracy

Despite advancements in technology, challenges remain in achieving high accuracy in SMT components counting:

Complex Component Designs

As electronic devices become more sophisticated, component designs are also evolving. Complex shapes may hinder accurate recognition by optical systems.

High-Speed Production Lines

In fast-paced manufacturing environments, maintaining accuracy while meeting production demands can be challenging. Balancing speed with precision requires careful planning and robust machinery capable of handling rapid throughput without sacrificing quality.

Cost Constraints

High-precision counting machines often come with significant upfront costs. Smaller manufacturers may find it challenging to invest in top-of-the-line equipment while still needing accurate counts to remain competitive.

Future Trends in SMT Components Counting Technology

The future of SMT components counting appears promising as technology continues to evolve:

Artificial Intelligence Integration

AI algorithms are being integrated into counting machines to improve recognition capabilities significantly. These advancements will enable machines to learn from previous data sets, enhancing their ability to count complex shapes accurately over time.

Enhanced Automation

As automation becomes more prevalent in manufacturing processes, counting machines will likely become increasingly integrated into automated assembly lines. This will streamline operations further while maintaining high levels of accuracy.

Data Analytics Utilization

Leveraging data analytics will allow manufacturers to gain insights into their counting processes. By analyzing trends over time, companies can identify areas for improvement and optimize their operations accordingly.

Conclusion

SMT components counting machines play a vital role in ensuring efficiency and accuracy within the electronics manufacturing industry. While various technologies exist with unique advantages and limitations, understanding these nuances is essential for selecting the right machine for specific needs. By implementing best practices such as regular maintenance, operator training, and integrating advanced technologies like AI, manufacturers can enhance their accuracy significantly. As technology continues to advance, we can expect even greater improvements in how we count SMT components—ultimately leading to more efficient production processes and higher quality electronic devices.

FAQ

1. What types of technologies are used in SMT components counting machines?

SMT components counting machines utilize various technologies such as optical recognition, weight measurement, laser scanning, and mechanical counting systems to ensure accurate counts based on component characteristics.

2. How does inaccurate component counting affect manufacturing?

Inaccurate component counting can lead to inventory management issues, production delays due to shortages or excess stock, increased waste costs due to defects during assembly processes, and overall inefficiencies within manufacturing operations.

3. What factors influence the accuracy of SMT components counting machines?

Factors influencing accuracy include component characteristics (shape, size), machine calibration frequency, environmental conditions (lighting), and operator training levels—all contributing to how well a machine performs its intended function.

4. How often should SMT components counting machines be calibrated?

Calibration frequency depends on usage intensity; however, regular checks—ideally monthly or quarterly—are recommended based on manufacturer specifications to ensure ongoing precision over time without unexpected discrepancies arising during operations.

5. What future trends should we expect in SMT component counting technology?

Future trends include increased integration of artificial intelligence for improved recognition capabilities; enhanced automation within assembly lines; greater utilization of data analytics providing insights into performance trends leading towards optimized operations across various manufacturing sectors.