Content Menu

● Introduction to SMT on Flex PCB

>> Benefits of SMT on Flex PCB

● Process of SMT Assembly on Flex PCB

>> Design Preparation

>> Material Selection

>> SMT Assembly Process

● Challenges and Limitations

● Advancements and Future Prospects

>> Role of Automation

>> Role of Advanced Materials

>> Role of 5G Technology

>> Role of AI and ML

● Applications of SMT on Flex PCB

● Future Prospects and Emerging Trends

>> Integration with IoT Devices

>> Advancements in Wearable Technology

>> Environmental Sustainability

● Conclusion

● FAQs

>> 1. What are the primary benefits of using SMT on flex PCBs?

>> 2. What are the common challenges faced in SMT assembly on flex PCBs?

>> 3. How does automation impact SMT assembly on flex PCBs?

>> 4. What are the key applications of SMT on flex PCBs?

>> 5. What advancements are being made in flex PCB SMT assembly?

The integration of Surface Mount Technology (SMT) with flexible printed circuit boards (Flex PCBs) has revolutionized the electronics industry by enabling the creation of high-density, compact, and reliable electronic devices. Flex PCBs are renowned for their flexibility, lightweight nature, and ability to conform to complex shapes, making them ideal for applications where space is limited or where the circuit board needs to be bent or curved. In this article, we will delve into the feasibility and benefits of using SMT for high-density flex PCB designs, exploring the process, advantages, challenges, and future prospects of this technology.

Introduction to SMT on Flex PCB

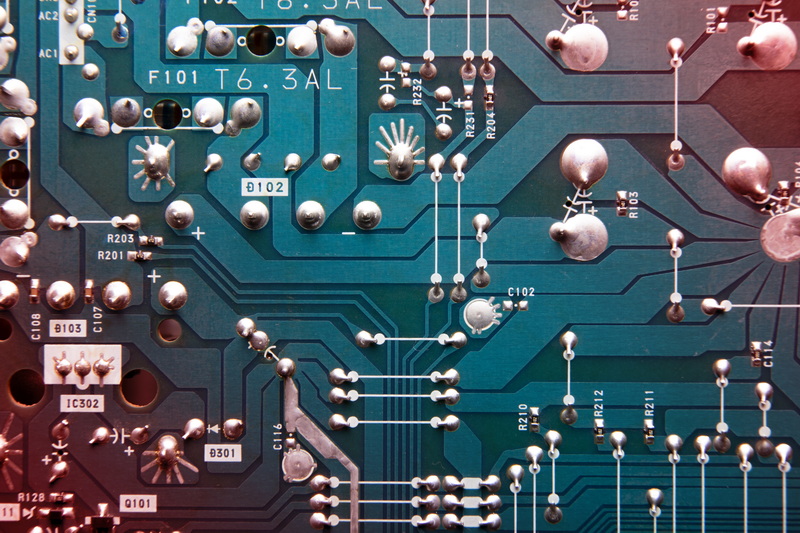

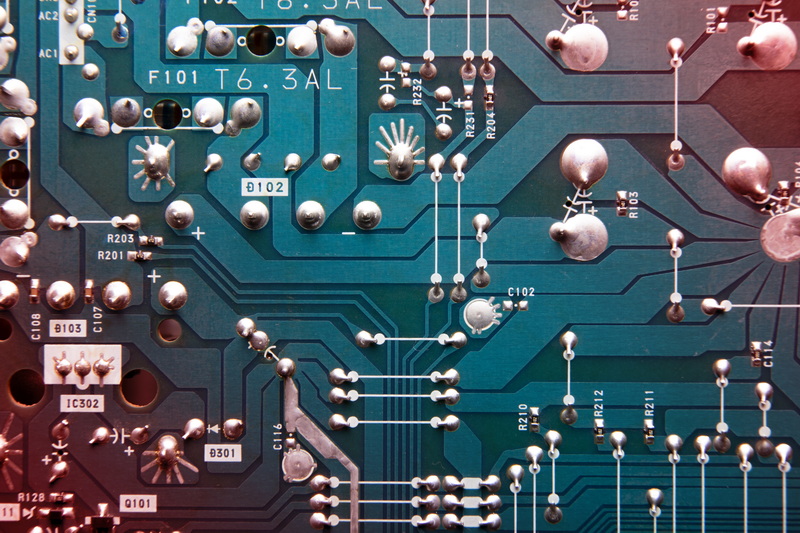

SMT is a widely used method for assembling electronic components onto printed circuit boards. It involves mounting components directly onto the surface of the PCB, which enhances component density, improves reliability, and reduces manufacturing time compared to traditional through-hole assembly methods. When applied to flex PCBs, SMT offers additional benefits such as space-saving designs, reduced weight, and improved reliability due to the flexibility of the PCBs.

Benefits of SMT on Flex PCB

1. Space-Saving Design: Flex PCBs can be designed to fit into tight spaces and can be bent or curved to fit the shape of the device they are being used in. This capability is particularly valuable in wearable technology, medical devices, and consumer electronics where compactness is crucial.

2. Reduced Weight: The lightweight nature of flex PCBs makes them ideal for portable devices or applications where weight is a concern. This reduces the overall weight of the device, enhancing portability and user experience.

3. Improved Reliability: Flex PCBs are less prone to mechanical failure than traditional rigid PCBs, making them more reliable in harsh environments or applications where the circuit board may be subject to vibration or movement.

4. Cost-Effectiveness: The flexibility of PCBs allows for manufacturing in various shapes and sizes, reducing waste and material costs. Additionally, SMT assembly can reduce labor costs and improve production efficiency.

Process of SMT Assembly on Flex PCB

The process of SMT assembly on flex PCBs involves several critical steps:

Design Preparation

- Designing the Flex PCB: The first step is creating a layout of the circuit and determining the appropriate materials to use. The design must consider the flexibility of the PCB and the components used in the SMT assembly process. Design for Manufacturability (DFM) principles are crucial here to ensure that the PCB design is optimized for efficient and cost-effective manufacturing.

Material Selection

- Choosing the right materials is essential for FPCB production. Common substrates include polyimide and polyester, which offer excellent flexibility and thermal stability. The selection of components also plays a vital role, as SMT requires surface-mounted devices (SMDs) that can be easily attached to the board.

SMT Assembly Process

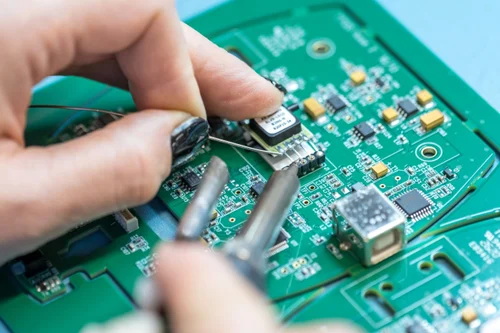

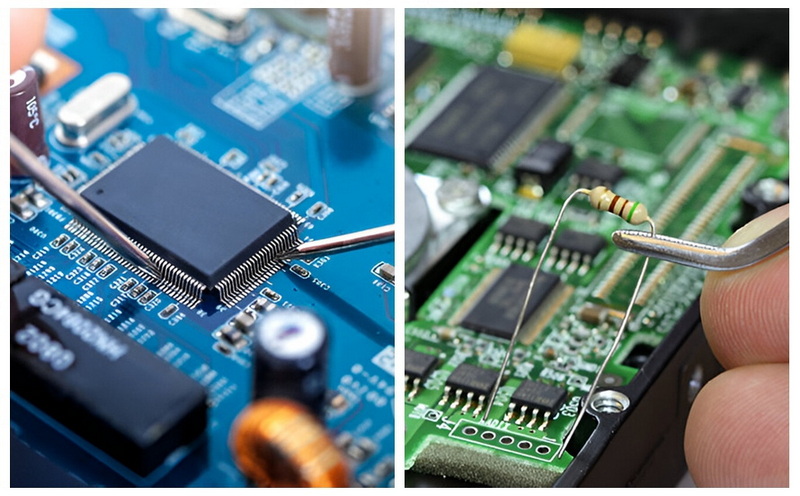

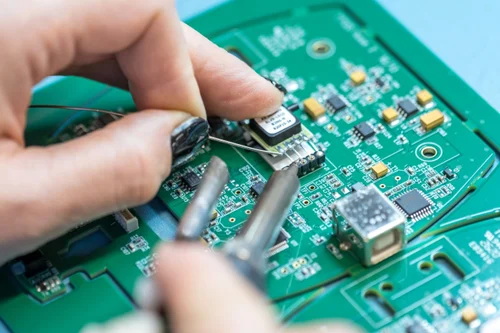

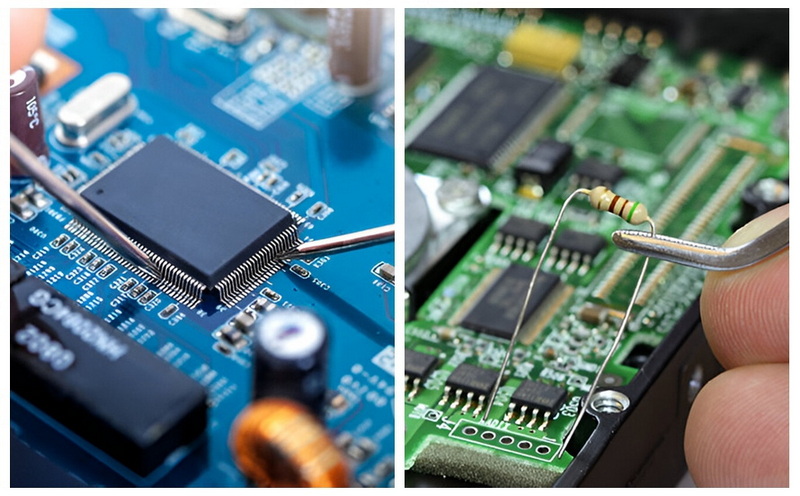

1. Component Placement: Electronic components are placed onto the flex PCB using automated pick-and-place machines. This process requires precision to ensure that components are correctly aligned and securely attached.

2. Soldering: After component placement, the PCB is sent through a reflow oven, where the solder paste is melted, and the components are soldered onto the PCB. This ensures that components are securely attached and connections are properly formed.

To prevent flex PCBs from bending or warping during the reflow process, they are often mounted onto a rigid carrier. This carrier provides support to the PCB and prevents it from deforming, ensuring that the SMT components are securely attached.

Challenges and Limitations

While SMT on flex PCB offers numerous advantages, there are also challenges to consider:

1. High Initial Investment Costs: Transitioning to SMT assembly requires significant upfront investment in specialized equipment like pick-and-place machines and reflow ovens.

2. Challenges with Fine Pitch Components: Assembling fine-pitch components requires advanced skills and precise equipment, which can be costly and challenging to manage.

3. Difficult Rework and Modifications: Due to the compact nature of SMT components, reworking or modifying assembled PCBs can be extremely difficult and may require complete disassembly and reassembly.

4. Stringent Process Controls: High-density SMT assemblies require tight process controls to avoid defects like solder shorts or insufficient solder joints.

5. Handling and Storage Issues: Flex PCBs are more delicate than rigid PCBs and require special care during handling and storage. Any bending or folding of the flex PCB can cause damage to the circuitry, resulting in failure during operation.

Advancements and Future Prospects

Recent advancements in flex PCB SMT assembly have focused on improving efficiency, precision, and cost-effectiveness. Innovations include the development of advanced materials that enhance durability and performance, allowing for lighter and thinner products without compromising functionality. Emerging techniques in SMT assembly enable greater precision and speed, impacting production timelines and costs positively.

Role of Automation

Automation plays a crucial role in modern flex PCB SMT assembly by reducing manual handling errors and optimizing placement accuracy. Technologies such as laser cutting and high-precision printing further elevate quality and reliability.

Role of Advanced Materials

The use of advanced materials like graphene and carbon nanotubes is expected to significantly impact the future of flex PCB SMT assembly. These materials are highly conductive, lightweight, and flexible, making them ideal for wearable devices and other applications where flexibility is essential.

Role of 5G Technology

The integration of 5G technology will enable faster data transfer rates, allowing for more complex designs and faster assembly times. This will also facilitate the creation of advanced sensors and devices, further enhancing the capabilities of flex PCB SMT assembly.

Role of AI and ML

Artificial Intelligence (AI) and Machine Learning (ML) algorithms are being used to optimize the design and assembly process, reducing errors and improving efficiency. These algorithms can predict potential issues before they occur, allowing for proactive maintenance and reducing downtime.

Applications of SMT on Flex PCB

SMT on flex PCBs is widely used in various industries due to its versatility and adaptability:

1. Consumer Electronics: Flex PCBs are used in devices like smartphones, tablets, and laptops due to their compactness and reliability.

2. Medical Devices: In medical devices, flex PCBs enable the creation of miniaturized equipment that improves patient care and diagnostics.

3. Automotive Systems: Flex PCBs are used to design lightweight, compact electronic systems that enhance vehicle performance and fuel efficiency.

4. Wearable Technology: The flexibility and compactness of flex PCBs make them ideal for wearable devices like smartwatches and fitness trackers.

Future Prospects and Emerging Trends

As technology continues to evolve, the future of SMT on flex PCBs looks promising. The integration of emerging technologies such as 5G, AI, and advanced materials will play a significant role in enhancing the capabilities of flex PCBs. These advancements will enable faster data transfer rates, improved efficiency, and the creation of more complex and reliable electronic devices.

Integration with IoT Devices

The increasing demand for Internet of Things (IoT) devices has created a need for compact, reliable, and efficient electronic systems. Flex PCBs, with their ability to conform to complex shapes and provide high-density component mounting, are well-suited for IoT applications. The use of SMT on flex PCBs in IoT devices will continue to grow as these devices become more prevalent in everyday life.

Advancements in Wearable Technology

Wearable technology is another area where SMT on flex PCBs is expected to play a crucial role. The flexibility and compactness of flex PCBs make them ideal for wearable devices like smartwatches, fitness trackers, and smart glasses. As wearable technology advances, the demand for high-density, reliable, and flexible PCBs will increase, driving further innovation in SMT assembly techniques.

Environmental Sustainability

The focus on reducing waste and minimizing defects aligns with environmental sustainability goals. By streamlining production processes and optimizing material usage, manufacturers can achieve higher yield rates while minimizing waste. This not only reduces environmental impact but also enhances the cost-effectiveness of production.

In summary, the integration of SMT with flex PCBs has opened up new possibilities in electronic device design and manufacturing. As technology continues to evolve, we can expect to see even more innovative applications of SMT on flex PCBs across various industries.

Conclusion

In conclusion, using SMT for high-density flex PCB designs is not only feasible but also highly beneficial. It offers advantages such as space-saving designs, reduced weight, improved reliability, and cost-effectiveness. While there are challenges associated with SMT assembly, advancements in technology and manufacturing processes continue to address these issues, making SMT on flex PCBs an increasingly attractive option for a wide range of applications.

FAQs

1. What are the primary benefits of using SMT on flex PCBs?

- The primary benefits include space-saving designs, reduced weight, improved reliability, and cost-effectiveness. SMT on flex PCBs allows for higher component density and faster production times, making it ideal for compact devices.

2. What are the common challenges faced in SMT assembly on flex PCBs?

- Common challenges include high initial investment costs, difficulties with fine-pitch components, and the need for stringent process controls to avoid defects. Additionally, reworking or modifying assembled PCBs can be challenging, and handling and storage require special care.

3. How does automation impact SMT assembly on flex PCBs?

- Automation significantly reduces manual handling errors and optimizes placement accuracy. It also streamlines production processes, leading to faster turnaround times and improved yields.

4. What are the key applications of SMT on flex PCBs?

- Key applications include consumer electronics, medical devices, automotive systems, and wearable technology. The flexibility and compactness of flex PCBs make them ideal for devices where space is limited.

5. What advancements are being made in flex PCB SMT assembly?

- Recent advancements focus on improving efficiency, precision, and cost-effectiveness. This includes the development of advanced materials, the integration of automation and high-precision technologies, and the use of AI and ML algorithms to enhance production quality and reduce waste.