Content Menu

● What is an SMT Stencil Kit?

● How Does a Quality SMT Stencil Kit Work?

● Time-Saving Benefits of Using a Quality SMT Stencil Kit

>> 1. Faster PCB Assembly Process

>> 2. Reduced Rework and Errors

>> 3. Simplified Prototype and Small Batch Production

● Money-Saving Advantages of a Quality SMT Stencil Kit

>> 1. Lower Labor Costs

>> 2. Reduced Material Waste

>> 3. Improved Yield and Quality

>> 4. Cost-Effective for Various Production Scales

● Key Features to Look for in a Quality SMT Stencil Kit

● How to Use an SMT Stencil Kit Effectively

>> 1. Preparation

>> 2. Alignment

>> 3. Printing

>> 4. Component Placement

>> 5. Reflow Soldering

>> 6. Inspection and Cleaning

● Additional Advantages of Using a Quality SMT Stencil Kit

>> Enhanced Repeatability and Consistency

>> Support for Advanced Components

>> Environmental and Safety Benefits

● Conclusion

● FAQ

>> 1. What is an SMT stencil kit used for?

>> 2. How does a laser-cut SMT stencil improve PCB assembly?

>> 3. Can SMT stencil kits save money in PCB production?

>> 4. Are SMT stencil kits suitable for prototype PCB assembly?

>> 5. What materials are SMT stencils made from?

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling faster, more precise, and cost-effective assembly of printed circuit boards (PCBs). Central to this technology is the SMT stencil kit, a tool that plays a crucial role in applying solder paste accurately on PCBs before component placement. This article explores how investing in a quality SMT stencil kit can save both time and money, enhancing production efficiency and product quality.

What is an SMT Stencil Kit?

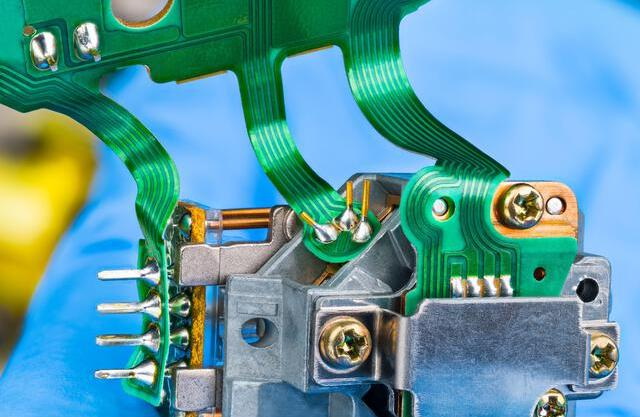

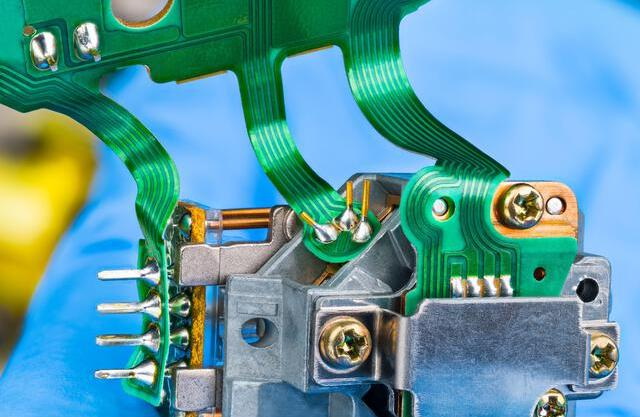

An SMT stencil kit typically includes a precision-cut stencil and sometimes a frame or other accessories designed to facilitate the application of solder paste onto PCB pads. The stencil acts as a template, allowing solder paste to be deposited only on specific areas where components will be soldered. This ensures precise solder volume and placement, which is critical for the reliability of the final electronic assembly.

The stencil itself is usually made from thin sheets of stainless steel or nickel alloy, laser-cut with microscopic apertures that correspond exactly to the PCB layout. These apertures define where solder paste will be applied, matching the pads on the PCB where surface mount devices (SMDs) will be placed.

How Does a Quality SMT Stencil Kit Work?

The stencil's precision and quality directly affect the solder paste printing process. During assembly, the stencil is aligned over the PCB, and solder paste is spread across the stencil openings using a squeegee or a stencil printer. This deposits solder paste only on the PCB pads where components will be mounted. The accuracy of this step is essential to ensure proper solder joint formation during reflow soldering.

A quality SMT stencil kit ensures:

- Accurate aperture dimensions: For consistent solder paste volume.

- Smooth aperture walls: To promote clean paste release.

- Durability: To withstand repeated use without deformation.

- Compatibility: With automated or manual printing equipment.

Time-Saving Benefits of Using a Quality SMT Stencil Kit

1. Faster PCB Assembly Process

Manual solder paste application is slow and prone to human error, especially with the increasing miniaturization of components and complex PCB designs. A quality SMT stencil kit enables rapid and uniform paste deposition, significantly speeding up the assembly process. Automated stencil printers can apply paste in seconds, compared to minutes or longer for manual methods.

This speed translates into higher throughput for manufacturers, allowing them to meet tight deadlines and scale production efficiently.

2. Reduced Rework and Errors

Precision in solder paste application reduces defects such as solder bridges, insufficient solder joints, or tombstoning of components. These defects often require time-consuming rework or scrapping of boards. Laser-cut SMT stencils provide smooth internal pad walls and consistent aperture sizes, improving paste release and reducing printing defects.

By minimizing these errors, manufacturers save valuable time that would otherwise be spent troubleshooting and repairing defective boards.

3. Simplified Prototype and Small Batch Production

For prototype or low-volume PCB assembly, a quality SMT stencil kit allows quick setup and printing without the need for expensive, time-consuming manual soldering. This accelerates development cycles and helps bring products to market faster.

The ability to rapidly produce stencils tailored to prototype designs means engineers can test and iterate quickly, saving weeks or months in product development.

Money-Saving Advantages of a Quality SMT Stencil Kit

1. Lower Labor Costs

Using an SMT stencil kit reduces the need for skilled manual labor to apply solder paste. Automated or semi-automated printing with stencils requires fewer operators, cutting labor expenses significantly. This is especially beneficial for high-volume production environments, where labor costs can be a major portion of total expenses.

2. Reduced Material Waste

Precise solder paste deposition means less excess paste is used, reducing material waste and lowering costs. Human application tends to be inconsistent, leading to overuse of solder paste and increased expenses. SMT stencil kits ensure the right amount of paste is applied every time, optimizing material usage.

Solder paste is an expensive consumable, so reducing waste directly impacts the bottom line.

3. Improved Yield and Quality

Higher quality solder joints reduce the number of defective boards and returns, saving money on repairs and replacements. Laser-cut stencils offer tight tolerances (as low as 5 microns), ensuring excellent paste placement for fine-pitch components and complex assemblies.

Improved yield means fewer boards discarded or reworked, which translates into significant cost savings over large production runs.

4. Cost-Effective for Various Production Scales

Whether for prototype runs or mass production, SMT stencil kits provide a scalable solution that balances cost and performance. For example, prototype stencils can be laser-cut to precise specifications and used with affordable reflow ovens, enabling small manufacturers or hobbyists to produce high-quality boards cost-effectively.

This flexibility means companies don't have to invest heavily in expensive equipment or processes to achieve professional results.

Key Features to Look for in a Quality SMT Stencil Kit

When selecting an SMT stencil kit, consider the following features to maximize your time and cost savings:

- Laser-Cut Precision: Ensures smooth aperture walls and consistent solder paste release, critical for fine-pitch components and complex PCB layouts.

- Material Quality: High nickel-content stainless steel offers strength, durability, and smooth surfaces for better printing performance and longer stencil life.

- Stencil Thickness: Varies between 0.002" to 0.015", affecting solder paste volume; choose thickness based on component size and PCB design requirements.

- Compatibility: Should be compatible with your stencil printer or manual printing setup for ease of use.

- Ease of Cleaning and Maintenance: Important for repeated use without clogging or damage, which can affect print quality.

- Customizable Apertures: Some kits allow for modifications or special aperture shapes to optimize paste deposition for unique components.

How to Use an SMT Stencil Kit Effectively

To maximize the benefits of your SMT stencil kit, follow these best practices:

1. Preparation

- Warm the solder paste to room temperature to ensure proper viscosity.

- Clean the PCB and stencil to remove dust, oils, or contaminants that could affect paste adhesion.

- Inspect the stencil for any damage or clogging before use.

2. Alignment

- Precisely align the stencil apertures with the PCB pads using fiducial marks or alignment tools.

- Proper alignment is crucial to avoid misprints and ensure solder paste is deposited exactly where required.

3. Printing

- Apply solder paste evenly across the stencil openings using a squeegee or stencil printer.

- Use consistent pressure and speed to ensure uniform paste thickness.

- Carefully lift the stencil to avoid smearing or disturbing the paste deposits.

4. Component Placement

- Place components on the solder-pasted PCB pads according to the bill of materials (BOM).

- Use automated pick-and-place machines or manual placement depending on production scale.

5. Reflow Soldering

- Heat the assembly in a reflow oven or with a hot air gun to melt the solder paste and secure the components.

- Follow recommended temperature profiles to avoid component damage or poor solder joints.

6. Inspection and Cleaning

- After cooling, inspect the solder joints visually or with automated optical inspection (AOI) systems.

- Clean the PCB if necessary to remove flux residues or paste smudges.

- Clean the stencil regularly to prevent aperture clogging and maintain print quality.

Additional Advantages of Using a Quality SMT Stencil Kit

Enhanced Repeatability and Consistency

One of the biggest advantages of a high-quality SMT stencil kit is the repeatability it offers. Each print is consistent in solder paste volume and placement, which is essential for automated assembly lines. This consistency reduces variability in the manufacturing process, leading to predictable and reliable outcomes.

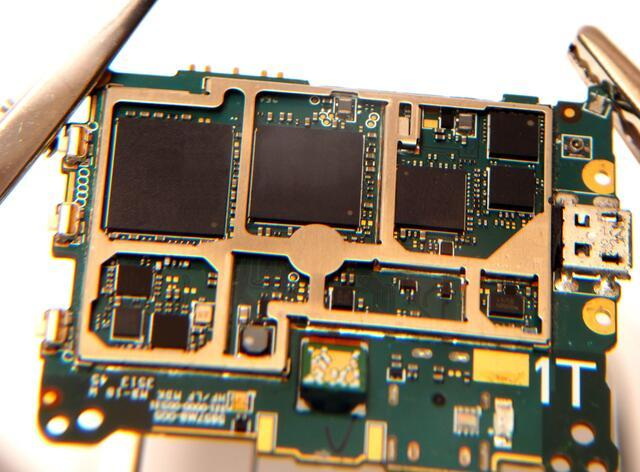

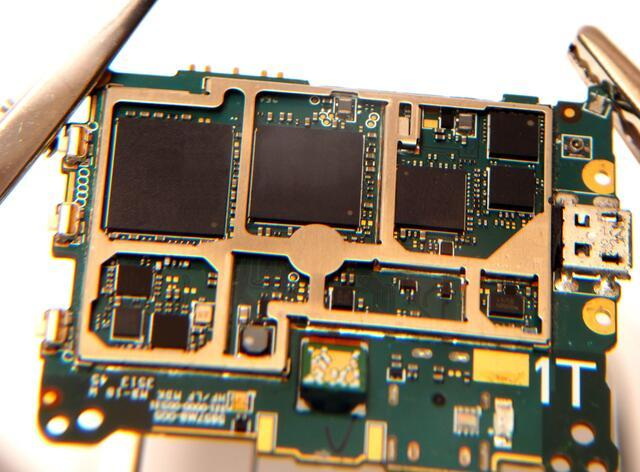

Support for Advanced Components

Modern electronics increasingly use fine-pitch components, micro BGAs, and other advanced packages that require extremely precise solder paste application. Quality SMT stencil kits with laser-cut apertures can meet these demanding requirements, enabling manufacturers to assemble cutting-edge devices without compromise.

Environmental and Safety Benefits

By reducing solder paste waste and minimizing rework, SMT stencil kits contribute to more sustainable manufacturing practices. Less waste means fewer hazardous materials to dispose of, and fewer defective boards reduce environmental impact. Additionally, automated printing reduces operator exposure to solder paste fumes and chemicals.

Conclusion

A quality SMT stencil kit is an indispensable tool in modern PCB assembly that offers significant time and cost savings. By enabling precise, consistent solder paste application, it accelerates production, reduces labor and material costs, and improves product quality. Whether you are a large-scale manufacturer or a small prototype developer, investing in a reliable SMT stencil kit can streamline your workflow, reduce errors, and ultimately enhance your bottom line.

The benefits of faster assembly, lower labor expenses, reduced material waste, and improved yield make a quality SMT stencil kit a smart investment for anyone involved in surface mount assembly. With the right stencil kit, you can achieve professional-grade PCB manufacturing results while saving valuable time and money.

FAQ

1. What is an SMT stencil kit used for?

An SMT stencil kit is used to apply solder paste accurately onto PCB pads during surface mount assembly, ensuring precise solder volume and placement for reliable solder joints.

2. How does a laser-cut SMT stencil improve PCB assembly?

Laser-cut stencils offer smooth aperture walls and high positional accuracy with tolerances as low as 5 microns, resulting in better solder paste release and fewer defects.

3. Can SMT stencil kits save money in PCB production?

Yes, they reduce labor costs, minimize solder paste waste, and improve yield by reducing defects and rework, leading to overall cost savings.

4. Are SMT stencil kits suitable for prototype PCB assembly?

Absolutely. Prototype SMT stencils are laser-cut to precise specifications and can be used with manual or small-scale printing setups, speeding up prototype assembly and reducing costs.

5. What materials are SMT stencils made from?

Most quality SMT stencils are made from high nickel-content stainless steel, which provides strength, durability, and smooth surfaces for superior solder paste release.