Content Menu

● Understanding SMT Stencil and Its Role in PCB Assembly

● How SMT Stencil Design Software Enhances PCB Layout Optimization

>> Key Benefits of SMT Stencil Design Software

>> Impact on PCB Layout Optimization

● Cost Optimization Through SMT Stencil Design Software

● Best Practices for Using SMT Stencil Design Software

● Conclusion

● FAQ

>> 1. What is SMT stencil design software?

>> 2. How does stencil thickness affect PCB assembly?

>> 3. Can SMT stencil design software reduce manufacturing costs?

>> 4. What are the types of SMT stencils supported by design software?

>> 5. How does SMT stencil design software integrate with PCB layout tools?

● Citations:

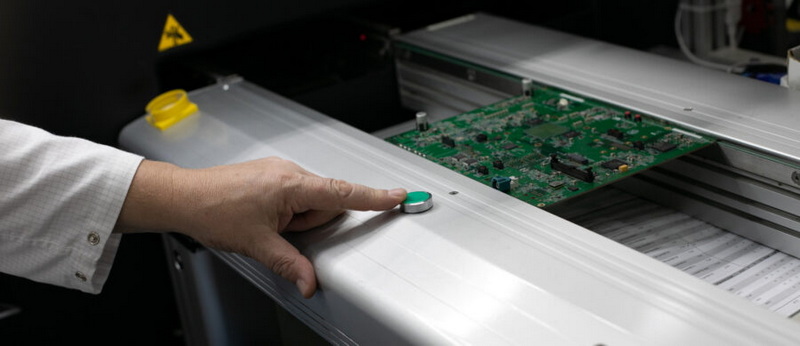

Surface Mount Technology (SMT) has revolutionized printed circuit board (PCB) assembly by enabling faster, more precise, and cost-effective manufacturing processes. A critical element in SMT assembly is the SMT stencil, which controls the application of solder paste on PCB pads. The design and optimization of these stencils directly affect the quality, yield, and cost of PCB production. With the advent of SMT stencil design software, engineers can now enhance PCB layouts and reduce manufacturing expenses more efficiently than ever before.

Understanding SMT Stencil and Its Role in PCB Assembly

An SMT stencil is a thin sheet, typically made of stainless steel or nickel, with precisely cut apertures that correspond to the PCB's solder pads. During assembly, solder paste is applied through these apertures onto the PCB, ensuring accurate paste volume and placement for surface mount components[10]. The stencil's design—its thickness, aperture size, and pattern—must align perfectly with the PCB layout to achieve high-quality solder joints.

Without a well-designed stencil, solder paste deposition can be inconsistent, leading to defects such as insufficient solder, bridging, or tombstoning, which degrade product reliability and increase rework costs[10].

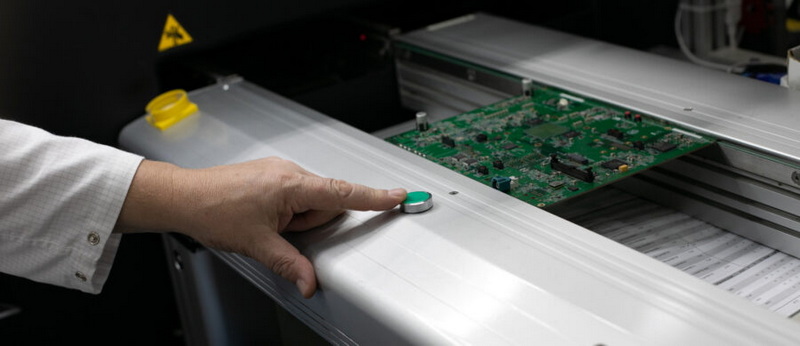

How SMT Stencil Design Software Enhances PCB Layout Optimization

Traditional stencil design often relies on manual processes and experience, which can introduce errors and inefficiencies. SMT stencil design software automates and streamlines this process by integrating with PCB layout data and applying design-for-manufacturing (DFM) principles.

Key Benefits of SMT Stencil Design Software

- Automated Aperture Generation and Optimization: The software can semi-automatically create stencil apertures based on a library of proven patterns, ensuring optimal solder paste volume and reducing trial-and-error in stencil fabrication[4].

- Maintaining Correct Aperture Ratios: Aperture-to-pad size ratios are critical to prevent solder paste from sticking inside stencil holes or causing shorts. Software tools analyze and adjust these ratios according to stencil thickness and component requirements[4].

- Support for Stepped Stencils: Some PCBs require varying stencil thicknesses to accommodate different component types or pitches. SMT stencil design software can incorporate step-up or step-down zones, improving solder paste deposition accuracy for complex layouts[3][4].

- Integration with PCB Layout Data: By reading Gerber files or PCB design data, the software performs automated checks such as area ratio calculations and flags potential issues before stencil manufacturing[3].

- Library Management and Knowledge Sharing: Design software allows maintaining multiple stencil pattern libraries tailored to customers, soldering technologies, or PCB finishes, facilitating consistent quality and knowledge transfer among engineers and subcontractors[4].

Impact on PCB Layout Optimization

SMT stencil design software encourages early collaboration between PCB layout engineers and assembly teams. By reviewing stencil requirements during PCB design, engineers can:

- Adjust pad sizes and spacing to optimize stencil aperture design and solder paste deposition[1][3].

- Group related components logically to reduce soldering defects and improve electrical performance[1].

- Incorporate test points and maintain proper component orientation to facilitate assembly and testing[1].

This synergy leads to PCB layouts that are not only electrically sound but also optimized for manufacturability and cost-efficiency.

Cost Optimization Through SMT Stencil Design Software

The choice and design of SMT stencils significantly influence production costs. Software-driven stencil design can reduce costs in several ways:

- Minimizing Solder Paste Usage: By optimizing aperture sizes and stencil thickness (e.g., using thinner stencils where possible), solder paste volume can be reduced by up to 37.5%, directly lowering material costs[2].

- Reducing Defects and Rework: Accurate stencil design improves print quality, which is the largest factor affecting end-of-line quality. Fewer defects mean lower scrap rates and less rework, translating into cost savings[3][10].

- Enabling Faster Setup and Changeover: Software-generated stencil designs can be produced and validated quickly, reducing downtime and speeding up production cycles[4].

- Supporting Different Stencil Types: Whether framed or frameless, the software can tailor designs to the appropriate stencil type, balancing precision and cost depending on production volume and equipment[6][7].

Best Practices for Using SMT Stencil Design Software

To maximize the benefits of SMT stencil design software, consider the following best practices:

- Early Design Review: Incorporate stencil design considerations during PCB layout to identify conflicting requirements and optimize pad design[3].

- Follow IPC Standards: Adhere to IPC-7525 and other relevant standards for stencil aperture design, step zones, and keepout areas to ensure print quality[3].

- Validate Designs Thoroughly: Use software tools to simulate solder paste deposition and check aperture ratios, minimizing surprises in production[4].

- Maintain Aperture Libraries: Build and update libraries of proven aperture designs to standardize quality and accelerate future projects[4].

- Collaborate Across Teams: Share stencil design data and knowledge among PCB designers, assembly engineers, and subcontractors to align goals and improve outcomes[4].

Conclusion

SMT stencil design software plays a pivotal role in optimizing PCB layouts and reducing manufacturing costs. By automating aperture design, ensuring proper solder paste deposition, and integrating closely with PCB data, this software enhances assembly quality and efficiency. Early collaboration and adherence to best practices enabled by these tools lead to more reliable, cost-effective SMT assemblies. As PCB complexity grows, leveraging SMT stencil design software becomes essential for competitive and high-quality electronics manufacturing.

FAQ

1. What is SMT stencil design software?

SMT stencil design software is a specialized tool that automates the creation and optimization of solder paste stencil patterns based on PCB layout data. It helps ensure accurate solder paste application by generating apertures with correct sizes, shapes, and spacing, improving assembly quality and reducing errors[4][3].

2. How does stencil thickness affect PCB assembly?

Stencil thickness determines the volume of solder paste deposited on PCB pads. Thicker stencils deposit more paste, suitable for larger components, while thinner stencils are used for fine-pitch components to avoid solder bridging. Software can help design stepped stencils with varying thicknesses to accommodate different component requirements on the same board[3][4].

3. Can SMT stencil design software reduce manufacturing costs?

Yes. By optimizing aperture sizes and stencil thickness, the software minimizes solder paste usage, reduces defects and rework, and accelerates production setup. These factors collectively lower material and operational costs in SMT assembly[2][3][4].

4. What are the types of SMT stencils supported by design software?

Design software supports various stencil types, including framed stencils for high-volume production and frameless stencils for prototyping or low-volume runs. The software can tailor designs to the specific stencil type to balance precision and cost[6][7].

5. How does SMT stencil design software integrate with PCB layout tools?

Most SMT stencil design software can import PCB layout files (e.g., Gerber files) to automatically generate stencil apertures aligned with PCB pads. This integration allows for automated checks like area ratio calculations and helps identify potential printing issues before manufacturing[3][4].

Citations:

[1] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[2] https://www.reddit.com/r/AskElectronics/comments/pk71xl/how_to_design_pcb_stencil_to_optimize_solder/

[3] https://www.ipc.org/system/files/technical_resource/E38&S12-02%20-%20Chrys%20Shea.pdf

[4] https://www.linkedin.com/pulse/smt-stencil-preparation-tips-tricks-design-software-alex-akulin-z2aif

[5] https://forums.autodesk.com/t5/eagle-forum/how-to-design-pcb-stencil-to-optimize-solder-paste-uses/td-p/10607754

[6] https://www.nextpcb.com/blog/smt-stencil

[7] https://www.instructables.com/How-to-Order-a-SMT-Stencil/

[8] https://www.reddit.com/r/PCB/comments/pk6z0i/how_to_design_pcb_stencil_to_optimize_solder/

[9] https://www.edaboard.com/threads/altium-designer-and-smt-stencil.237150/

[10] https://jlcpcb.com/blog/why-pcb-stencils-are-key-to-high-quality-smt-assembly

[11] https://www.surfacemountprocess.com/a-guide-to-effective-stencil-design.html

[12] https://www.eeweb.com/how-and-why-the-utilization-of-smt-stencils-simplify-the-process-of-pcb-prototyping/