Content Menu

● Introduction to SMT Stencil Cleaning

>> Importance of Stencil Cleaning

● Common Errors in SMT Production

● Methods of SMT Stencil Cleaning

● Benefits of Effective Stencil Cleaning

● Challenges in Stencil Cleaning

● Future Developments in SMT Stencil Cleaning

● Case Studies on Effective Stencil Cleaning

● Best Practices for Implementing SMT Stencil Cleaning

● Advanced Technologies in Stencil Cleaning

● Impact of Stencil Cleaning on Supply Chain Efficiency

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of SMT stencil cleaning?

>> 2. How often should SMT stencils be cleaned?

>> 3. What are the common methods for cleaning SMT stencils?

>> 4. What are the environmental and safety considerations for SMT stencil cleaning?

>> 5. How does stencil cleaning impact the overall quality of electronic assemblies?

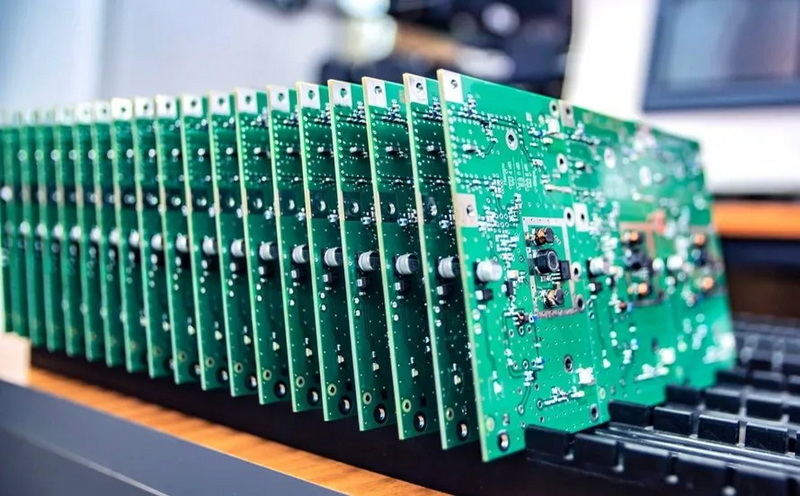

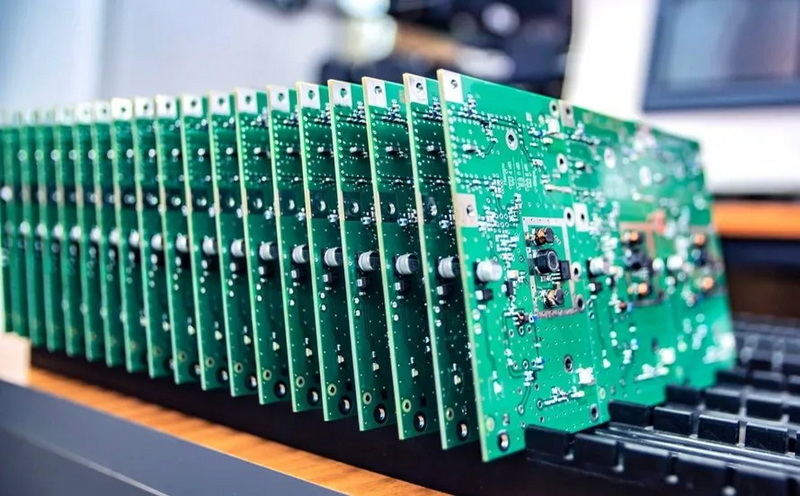

Surface Mount Technology (SMT) is a crucial process in the electronics manufacturing industry, involving the placement of components onto a printed circuit board (PCB). One of the most critical steps in this process is the application of solder paste through stencils. However, defects can arise if the stencils are not properly cleaned, leading to significant production errors. In this article, we will explore the importance of SMT stencil cleaning in reducing production errors and enhancing overall manufacturing efficiency.

Introduction to SMT Stencil Cleaning

SMT stencil cleaning is essential for ensuring accurate solder paste application and improving solder joint quality. Stencils are used to apply solder paste onto the PCB pads, and any residue left on the stencil can cause misprints, leading to bridging and solder balling issues. These issues not only increase the cost of rework but also reduce the reliability of the final product.

Importance of Stencil Cleaning

Stencil cleaning is crucial for several reasons:

1. Accurate Solder Paste Application: Clean stencils ensure that the correct amount of solder paste is deposited onto the PCB pads, reducing the risk of insufficient solder or excessive solder that can cause bridging.

2. Improved Solder Joint Quality: Proper cleaning helps in achieving consistent solder joints, which are vital for the reliability and performance of electronic assemblies.

3. Reduction in Scrap and Rework: By minimizing defects related to solder paste application, stencil cleaning reduces the need for costly rework and scrap disposal.

4. Prolonged Stencil Life: Regular cleaning extends the lifespan of stencils by preventing the buildup of hardened solder paste residues, which can damage the stencil material over time.

5. Compliance with Industry Standards: Clean stencils are necessary for meeting industry standards, such as those set by the IPC (Institute for Printed Circuits).

Common Errors in SMT Production

Several common errors in SMT production can be mitigated through effective stencil cleaning:

1. Insufficient Fills and Insufficient Solder: This issue often arises when stencil apertures are clogged with dried solder paste, preventing adequate solder paste deposition.

2. Solder Balling: Moisture contamination, poor reflow profiles, and excessive oxides in solder paste can lead to solder balling. While cleaning does not directly prevent solder balling, maintaining a clean environment reduces the risk of moisture contamination.

3. Bridging: Excessive solder paste or misaligned printing can cause bridging between components. Clean stencils help ensure precise solder paste application, reducing this risk.

Methods of SMT Stencil Cleaning

There are several methods for cleaning SMT stencils, each with its advantages:

1. Manual Cleaning: This method involves using cleaning agents to manually wipe down the stencil. However, it can cause mechanical damage and soften the stencil epoxy over time, leading to delamination issues.

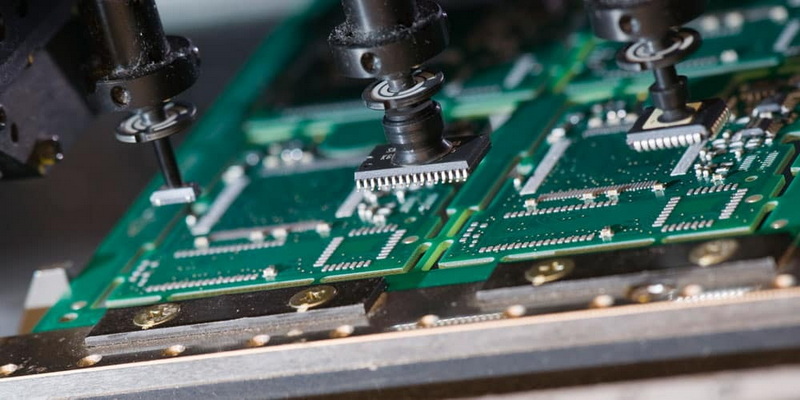

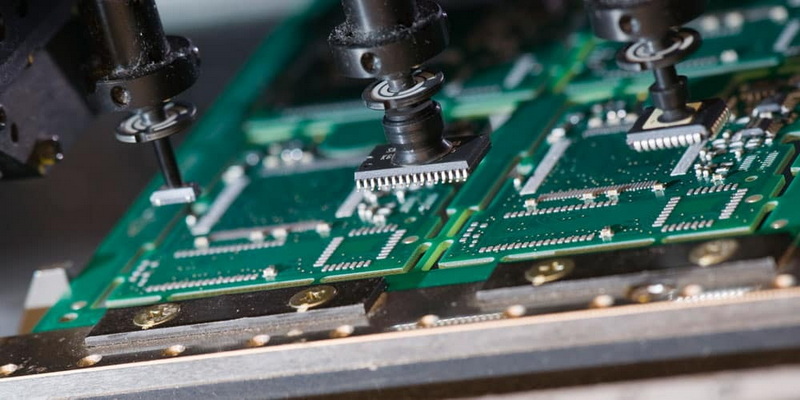

2. Automated Cleaning: Automated systems provide reproducible cleaning results and minimize mechanical damage. They are preferred for high-volume production environments.

3. Chemical Cleaning Agents: Various cleaning agents are available, including aqueous and solvent-based cleaners. The choice of agent depends on the type of stencil material and the level of contamination.

4. Ultrasonic and Spray Cleaning: These methods use ultrasonic waves or spray jets to dislodge solder paste residues from the stencil. They are effective for fine pitch and nano-coated stencils.

Benefits of Effective Stencil Cleaning

Effective SMT stencil cleaning offers several benefits:

- Improved Production Efficiency: By reducing defects and rework, stencil cleaning helps maintain a smooth production flow.

- Cost Savings: Minimizing scrap and rework reduces overall production costs.

- Enhanced Product Quality: Clean stencils ensure consistent solder paste application, leading to higher-quality electronic assemblies.

- Environmental and Safety Compliance: Modern cleaning agents and methods are designed to be environmentally friendly and safe for workers, reducing VOCs and other hazards.

Challenges in Stencil Cleaning

Despite its importance, stencil cleaning poses some challenges:

1. Choosing the Right Cleaning Agent: The agent must be effective, safe for the stencil material, and environmentally friendly.

2. Maintaining Cleaning Frequency: Regular cleaning is crucial to prevent residue buildup, but over-cleaning can damage the stencil.

3. Balancing Cost and Efficiency: Automated systems offer better results but may be more expensive than manual methods.

Future Developments in SMT Stencil Cleaning

As SMT technology advances, stencil cleaning processes are also evolving:

1. Advanced Materials and Designs: New stencil materials and designs are being developed to improve accuracy and efficiency.

2. Innovative Cleaning Technologies: Research into more effective and environmentally friendly cleaning agents and methods continues.

3. Integration with Industry 4.0: Automated cleaning systems are being integrated with smart manufacturing technologies to enhance efficiency and reduce human error.

Case Studies on Effective Stencil Cleaning

Several companies have seen significant improvements in production efficiency and quality by implementing effective stencil cleaning practices:

1. Increased Throughput: By reducing rework and defects, companies can increase production throughput, meeting customer demands more effectively.

2. Cost Reduction: Minimizing scrap and rework not only saves costs but also reduces waste disposal expenses.

3. Improved Customer Satisfaction: Consistent product quality enhances customer satisfaction, leading to repeat business and positive referrals.

Best Practices for Implementing SMT Stencil Cleaning

To maximize the benefits of stencil cleaning, manufacturers should follow best practices:

1. Regular Maintenance Schedules: Establish a routine cleaning schedule based on usage and contamination levels.

2. Training Personnel: Ensure that staff are trained in proper cleaning techniques and safety protocols.

3. Monitoring Cleaning Effectiveness: Regularly inspect stencils for cleanliness and adjust cleaning methods as needed.

4. Investing in Quality Equipment: Use high-quality cleaning agents and equipment to ensure effective cleaning without damaging stencils.

Advanced Technologies in Stencil Cleaning

The integration of advanced technologies is transforming the stencil cleaning process:

1. AI and Machine Learning: These technologies can optimize cleaning schedules and detect potential issues before they occur.

2. IoT Sensors: Real-time monitoring of stencil cleanliness and production conditions helps in making data-driven decisions.

3. Robotics: Automated robotic systems can perform precise cleaning tasks, reducing human error and improving efficiency.

Impact of Stencil Cleaning on Supply Chain Efficiency

Effective stencil cleaning also impacts the supply chain by ensuring consistent product quality and reducing lead times:

1. Reduced Inventory Costs: By minimizing defects, manufacturers can maintain lower inventory levels, reducing storage costs.

2. Improved Supplier Relationships: Consistent quality helps in building strong relationships with suppliers, leading to better pricing and service.

3. Enhanced Logistics Efficiency: Reduced rework and scrap enable smoother logistics operations, as fewer products need to be returned or repaired.

Conclusion

SMT stencil cleaning is a critical step in reducing production errors and enhancing the quality of electronic assemblies. By ensuring accurate solder paste application and minimizing defects, stencil cleaning plays a vital role in maintaining production efficiency and reducing costs. As technology continues to evolve, the importance of effective stencil cleaning will only grow, necessitating ongoing innovation in cleaning methods and materials.

Frequently Asked Questions

1. What are the primary benefits of SMT stencil cleaning?

SMT stencil cleaning improves solder joint quality, reduces scrap and rework, prolongs stencil life, and ensures compliance with industry standards. It also enhances production efficiency by minimizing defects related to solder paste application.

2. How often should SMT stencils be cleaned?

Stencils should be cleaned regularly to prevent residue buildup. The frequency depends on usage and the type of solder paste used. Automated cleaning systems can provide consistent results and reduce the need for frequent manual intervention.

3. What are the common methods for cleaning SMT stencils?

Common methods include manual cleaning with agents, automated cleaning systems, ultrasonic cleaning, and spray cleaning. The choice of method depends on the stencil material, level of contamination, and production volume.

4. What are the environmental and safety considerations for SMT stencil cleaning?

Modern cleaning agents are designed to be environmentally friendly and safe for workers. They minimize VOCs and other hazards associated with traditional solvents like isopropyl alcohol. Automated systems also reduce the risk of mechanical damage and exposure to chemicals.

5. How does stencil cleaning impact the overall quality of electronic assemblies?

Proper stencil cleaning ensures accurate solder paste application, which is critical for achieving consistent and reliable solder joints. This directly impacts the performance and reliability of the final electronic assembly, reducing the risk of defects and improving overall product quality.