Content Menu

● Introduction to SMT Reel Counter Machines

>> Key Features of SMT Reel Counter Machines

● How SMT Reel Counters Reduce Production Downtime

● Benefits of Using SMT Reel Counter Machines

● Applications of SMT Reel Counter Machines

● Future Developments and Challenges

● Case Studies and Real-World Applications

● Conclusion

● FAQs

>> 1. What is the primary function of an SMT reel counter machine?

>> 2. How do SMT reel counters improve production efficiency?

>> 3. Can SMT reel counters handle different types of components?

>> 4. How do SMT reel counters enhance quality control?

>> 5. Can SMT reel counters integrate with inventory management systems?

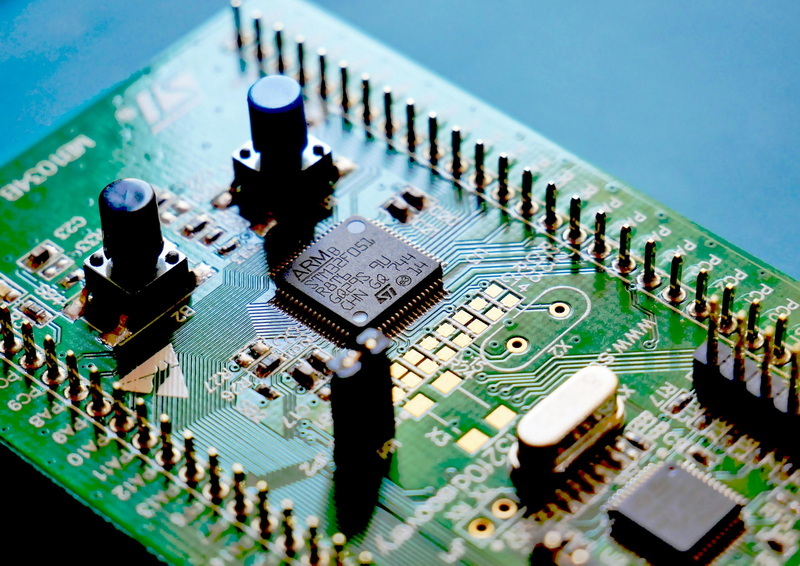

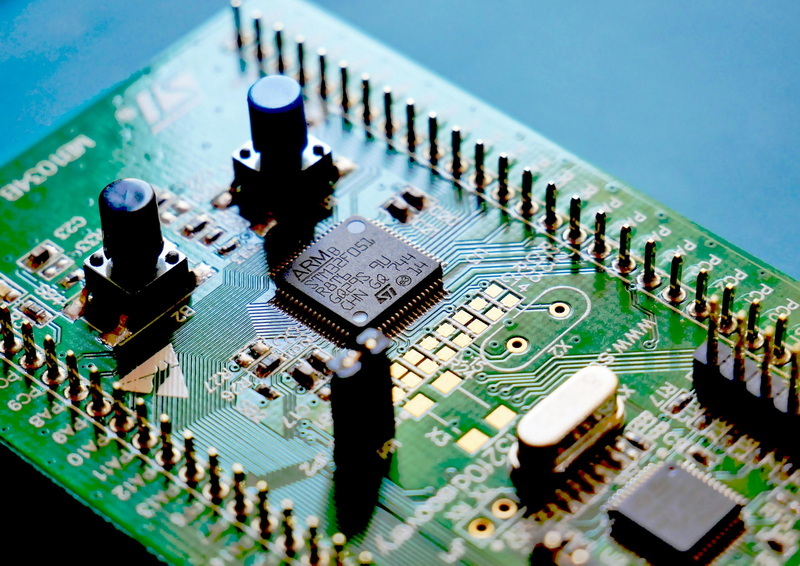

In the fast-paced world of electronics manufacturing, particularly in the realm of Surface Mount Technology (SMT), efficiency and precision are paramount. One of the critical tools that have emerged to enhance production efficiency is the SMT reel counter machine. These machines are designed to accurately count components on reels, ensuring that the production line runs smoothly and that inventory management is optimized. But can SMT reel counters help reduce production downtime? This article will delve into the role of SMT reel counters in minimizing production interruptions and explore their broader benefits in the manufacturing process.

Introduction to SMT Reel Counter Machines

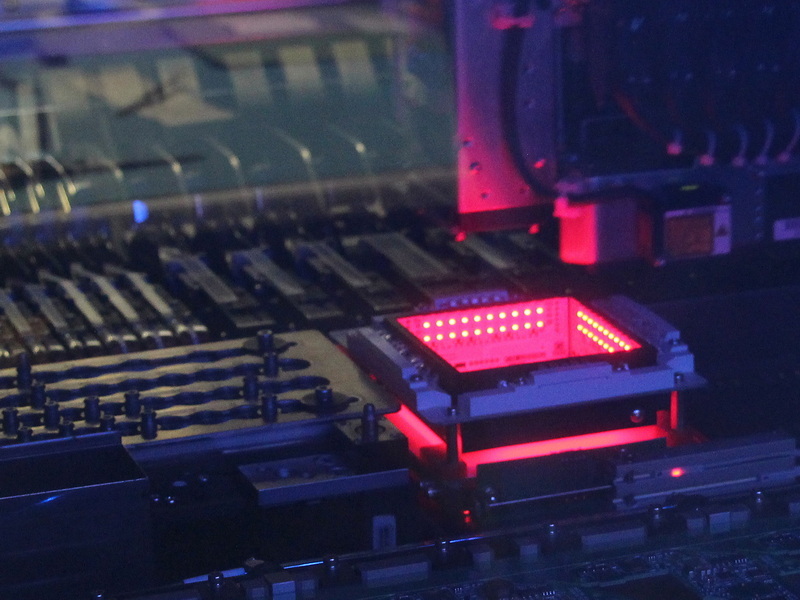

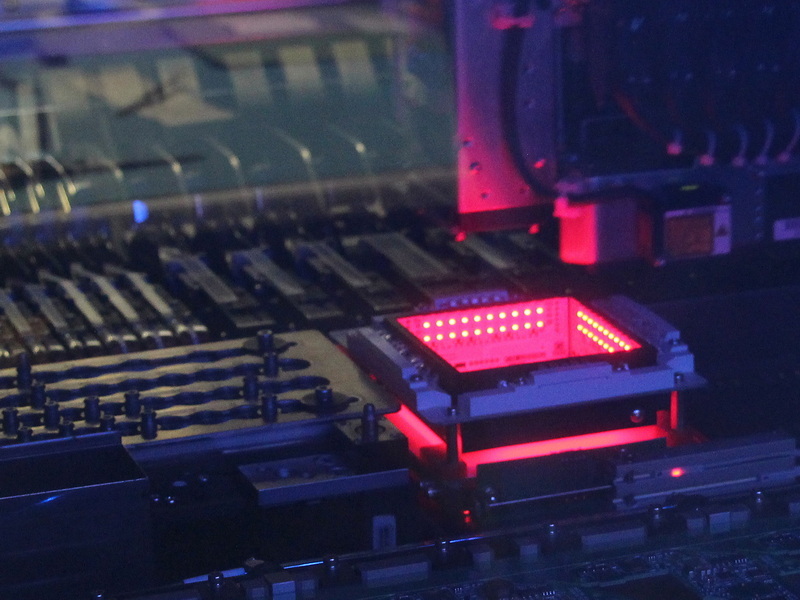

SMT reel counter machines are automated devices that use advanced technologies such as optical sensors and high-speed counting mechanisms to accurately determine the number of components on a reel. Unlike manual counting methods, which are time-consuming and prone to errors, these machines provide precise counts, reducing the likelihood of material shortages or excesses that can halt production.

Key Features of SMT Reel Counter Machines

1. Accuracy and Speed: These machines can count components quickly and accurately, reducing the time spent on inventory management and allowing for real-time updates of stock levels.

2. Automation: By automating the counting process, SMT reel counters minimize manual intervention, which is a common source of errors and inefficiencies.

3. Versatility: They can handle a variety of component types and reel sizes, making them versatile for different production needs.

How SMT Reel Counters Reduce Production Downtime

Production downtime in electronics manufacturing can be costly, often resulting from material shortages, inventory mismanagement, or component defects. SMT reel counters play a crucial role in mitigating these issues:

1. Accurate Inventory Management: By providing precise counts of components, SMT reel counters help manufacturers maintain accurate inventory levels. This ensures that production lines are always supplied with the necessary materials, reducing the risk of shortages that can lead to downtime.

2. Efficient Material Allocation: These machines enable real-time monitoring of component usage, allowing for timely procurement and minimizing the likelihood of stockouts or overstocking, both of which can disrupt production.

3. Fault Detection: Many SMT reel counters come equipped with fault detection capabilities, such as missing part detection, which helps prevent defective components from entering the production line. This reduces the need for rework and scrap, further minimizing downtime.

4. Streamlined Production Process: By automating the counting process, SMT reel counters free up labor resources that can be redirected to more critical tasks, enhancing overall production efficiency and reducing the potential for bottlenecks.

Benefits of Using SMT Reel Counter Machines

Beyond reducing production downtime, SMT reel counter machines offer several other benefits that enhance manufacturing efficiency:

1. Cost Savings: By reducing manual labor and minimizing errors, these machines help lower production costs. Additionally, accurate inventory management avoids unnecessary purchases and material waste.

2. Improved Quality Control: The ability to detect missing or defective components ensures that only high-quality components are used in production, reducing the risk of defective products and subsequent rework.

3. Enhanced Productivity: With automated counting, manufacturers can focus on more strategic tasks, leading to increased productivity and faster response times to changes in demand.

4. Integration with Other Systems: Many SMT reel counters can integrate with inventory management systems, providing real-time updates and enhancing supply chain efficiency.

Applications of SMT Reel Counter Machines

SMT reel counter machines are not limited to electronics manufacturing; they can be applied across various industries where component accuracy is crucial:

1. Electronics Manufacturing: Critical for SMT production lines where component precision is vital.

2. Automotive Industry: Used for counting and quality control of automotive electronic components.

3. Inventory Management: Essential for maintaining accurate stock levels and optimizing supply chains.

Future Developments and Challenges

As technology advances, SMT reel counters are likely to integrate more sophisticated features such as AI and machine learning to enhance their capabilities. For instance, AI can be used to predict component usage patterns, allowing for proactive inventory management. However, challenges remain, including the need for seamless integration with existing production lines and ensuring the machines can handle a wide range of component types without compromising accuracy.

Moreover, the integration of IoT technologies can enable real-time monitoring and remote management of SMT reel counters, further enhancing their efficiency and reducing maintenance downtime. Despite these potential advancements, manufacturers must also consider the initial investment costs and ensure that these machines align with their production strategies and budgets.

Case Studies and Real-World Applications

Several companies have successfully implemented SMT reel counters to improve their production processes. For example, a leading electronics manufacturer reported a significant reduction in inventory discrepancies and production delays after integrating SMT reel counters into their supply chain management system. This not only improved their operational efficiency but also enhanced their ability to meet customer demand more effectively.

Another case involves a smaller electronics firm that used SMT reel counters to streamline their component inventory management. By automating the counting process, they were able to redirect labor resources to more critical tasks, such as product development and quality assurance, leading to increased competitiveness in the market.

Conclusion

In conclusion, SMT reel counter machines play a pivotal role in reducing production downtime by ensuring accurate inventory management, efficient material allocation, and fault detection. These machines not only enhance production efficiency but also contribute to cost savings, improved quality control, and increased productivity. As the electronics manufacturing industry continues to evolve, the importance of SMT reel counters will only grow, making them an indispensable tool for modern production environments.

FAQs

1. What is the primary function of an SMT reel counter machine?

- The primary function of an SMT reel counter machine is to accurately count the number of components on a reel, automating the inventory management process and reducing manual errors.

2. How do SMT reel counters improve production efficiency?

- SMT reel counters improve production efficiency by automating the counting process, reducing manual labor, and providing real-time inventory updates, which helps in minimizing production downtime and optimizing material usage.

3. Can SMT reel counters handle different types of components?

- Yes, SMT reel counters are designed to handle a variety of component types, including resistors, capacitors, and ICs, making them versatile for different production needs.

4. How do SMT reel counters enhance quality control?

- SMT reel counters enhance quality control by detecting missing or defective components, ensuring that only high-quality components are used in production, which reduces the risk of defective products.

5. Can SMT reel counters integrate with inventory management systems?

- Yes, many SMT reel counters can integrate with inventory management systems, providing real-time updates and enhancing supply chain efficiency.