Content Menu

● Understanding PCB SMT Standoffs

>> Key Features of PCB SMT Standoffs

● The SMT Assembly Process

● Cost Reduction Benefits of PCB SMT Standoffs

>> Increased Production Efficiency

>> Improved Quality Control

>> Material Cost Savings

● Enhanced PCB Performance and Reliability

>> Thermal Management

>> Mechanical Stability

>> Electrical Performance

● Implementation Considerations

>> Design Considerations

>> Manufacturing Process Adaptation

>> Material Selection

● Case Studies: Success Stories in Cost Reduction

>> Case Study 1: Consumer Electronics Manufacturer

>> Case Study 2: Automotive Electronics Supplier

>> Case Study 3: Industrial IoT Device Maker

● Future Trends in PCB SMT Standoff Technology

● Challenges and Limitations

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the main advantages of using PCB SMT standoffs?

>> 2. How do PCB SMT standoffs compare to traditional through-hole standoffs?

>> 3. Are there any limitations to using PCB SMT standoffs?

>> 4. What factors should be considered when selecting PCB SMT standoffs?

>> 5. How can PCB SMT standoffs contribute to overall product reliability?

● Citations:

In the ever-evolving world of electronics manufacturing, finding ways to reduce costs while maintaining or improving quality is a constant challenge. One area where significant advancements have been made is in the use of Surface Mount Technology (SMT) standoffs for Printed Circuit Boards (PCBs). This article will explore how PCB SMT standoffs can contribute to cost reduction in PCB manufacturing, their benefits, and their impact on the overall production process.

Understanding PCB SMT Standoffs

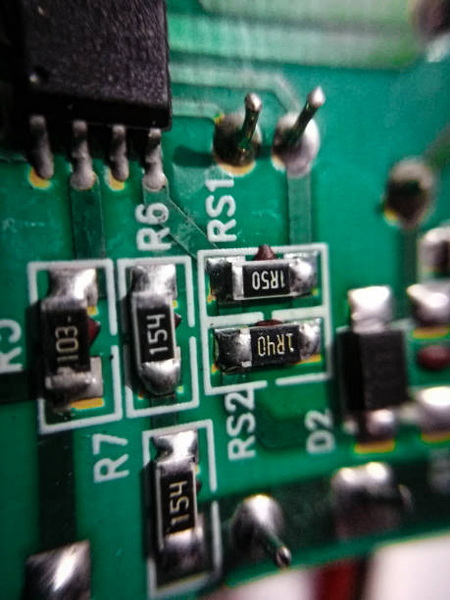

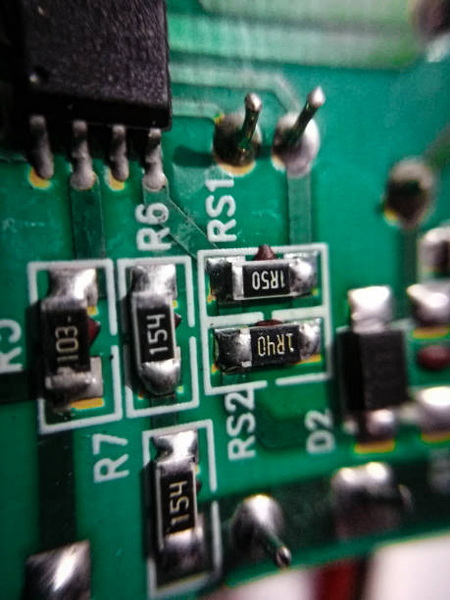

PCB SMT standoffs are specialized components designed to provide support and spacing for circuit boards. Unlike traditional through-hole standoffs, SMT standoffs are surface-mounted directly onto the PCB, allowing for a more streamlined and efficient manufacturing process[1].

Key Features of PCB SMT Standoffs

1. Automated Installation: PCB SMT standoffs are designed for fully automated installation as part of the PCB manufacturing process[5].

2. Enhanced Stability: They provide mechanical stability and support to the PCB, preventing flexing and warping[1].

3. Improved Heat Dissipation: By creating space between the PCB and other components, SMT standoffs enhance airflow and heat dissipation[1].

4. Electrical Isolation: When made from insulating materials, they can provide electrical isolation, preventing short circuits[1].

The SMT Assembly Process

To understand how PCB SMT standoffs contribute to cost reduction, it's essential to grasp the SMT assembly procedure. The process typically involves the following steps:

1. Solder paste printing

2. Solder paste inspection (SPI)

3. Component placement

4. Visual inspection

5. Reflow soldering[2]

PCB SMT standoffs are integrated into this process, allowing for simultaneous installation with other surface-mount components.

Cost Reduction Benefits of PCB SMT Standoffs

Increased Production Efficiency

One of the primary ways PCB SMT standoffs help reduce manufacturing costs is by increasing production efficiency. Traditional standoffs often require manual installation, which can be time-consuming and prone to errors. In contrast, SMT standoffs can be placed using the same automated equipment used for other surface-mount components[1].

This automation leads to:

- Faster assembly times

- Reduced labor costs

- Minimized human error

- Increased throughput

Improved Quality Control

The automated nature of SMT standoff installation contributes to better quality control. With precise placement and consistent soldering, the risk of misalignment or poor connections is significantly reduced. This improvement in quality leads to:

- Fewer defects

- Reduced rework and scrap rates

- Lower warranty and return costs

Material Cost Savings

PCB SMT standoffs can also contribute to material cost savings in several ways:

1. Reduced PCB Size: By eliminating the need for through-holes, PCBs can potentially be designed smaller, using less material.

2. Minimized Component Damage: The automated process reduces the risk of damage to other components during assembly, lowering replacement costs.

3. Optimized Inventory Management: With SMT standoffs being part of the automated assembly process, inventory management becomes more streamlined, potentially reducing carrying costs.

Enhanced PCB Performance and Reliability

While cost reduction is a significant benefit, PCB SMT standoffs also contribute to improved performance and reliability of the final product.

Thermal Management

By creating space between the PCB and other components or surfaces, SMT standoffs improve airflow and heat dissipation. This enhanced thermal management can lead to:

- Improved component longevity

- Reduced risk of thermal-related failures

- Potential for higher-performance designs

Mechanical Stability

PCB SMT standoffs provide crucial mechanical support to the circuit board. This increased stability results in:

- Reduced risk of PCB flexing or warping

- Improved shock and vibration resistance

- Enhanced overall product durability

Electrical Performance

When used in high-frequency applications, PCB SMT standoffs can help control impedance by maintaining a consistent distance between the PCB and ground plane. This can lead to improved signal integrity and reduced electromagnetic interference (EMI)[4].

Implementation Considerations

While the benefits of PCB SMT standoffs are clear, successful implementation requires careful consideration of several factors.

Design Considerations

When incorporating PCB SMT standoffs into a design, engineers should consider:

- Proper placement for optimal support and thermal management

- Compatibility with other components and manufacturing processes

- Appropriate standoff height and material selection based on application requirements

Manufacturing Process Adaptation

Integrating PCB SMT standoffs into the production line may require:

- Updating pick-and-place machine programming

- Adjusting reflow soldering profiles

- Modifying quality control and inspection procedures

Material Selection

Choosing the right material for PCB SMT standoffs is crucial. Options include:

- Brass: Offers good conductivity and strength

- Stainless Steel: Provides excellent durability and corrosion resistance

- Nylon: Offers electrical insulation and lightweight properties

The selection should be based on the specific requirements of the application, including electrical, thermal, and mechanical considerations.

Case Studies: Success Stories in Cost Reduction

To illustrate the real-world impact of PCB SMT standoffs on manufacturing costs, let's examine a few hypothetical case studies.

Case Study 1: Consumer Electronics Manufacturer

A large consumer electronics manufacturer implemented PCB SMT standoffs in their smartphone production line. The results included:

- 15% reduction in assembly time

- 8% decrease in overall manufacturing costs

- 30% reduction in PCB-related defects

Case Study 2: Automotive Electronics Supplier

An automotive electronics supplier switched to PCB SMT standoffs for their engine control units. They observed:

- 20% improvement in production throughput

- 12% reduction in material costs due to optimized PCB design

- 25% decrease in warranty claims related to PCB failures

Case Study 3: Industrial IoT Device Maker

A manufacturer of industrial IoT devices adopted PCB SMT standoffs and reported:

- 18% reduction in labor costs

- 10% improvement in thermal performance of their devices

- 22% decrease in PCB size, leading to material savings

These case studies demonstrate the significant cost-saving potential of implementing PCB SMT standoffs across various industries and applications.

Future Trends in PCB SMT Standoff Technology

As technology continues to advance, we can expect further innovations in PCB SMT standoff design and manufacturing. Some potential future trends include:

1. Miniaturization: As electronic devices continue to shrink, we may see even smaller SMT standoffs designed for ultra-compact PCBs.

2. Advanced Materials: Development of new materials with enhanced thermal, electrical, or mechanical properties could further improve standoff performance.

3. Integration with Other Components: We might see SMT standoffs that combine multiple functions, such as heat sinking or signal routing, further optimizing PCB design and manufacturing.

4. Smart Manufacturing: Integration of PCB SMT standoffs into Industry 4.0 and smart manufacturing systems could lead to even greater efficiencies and cost savings.

5. Sustainability: As environmental concerns grow, we may see a focus on more eco-friendly materials and manufacturing processes for PCB SMT standoffs.

Challenges and Limitations

While PCB SMT standoffs offer numerous benefits, it's important to acknowledge some challenges and limitations:

1. Initial Investment: Implementing SMT standoffs may require initial investments in equipment and process changes.

2. Design Complexity: Incorporating SMT standoffs can increase PCB design complexity, potentially requiring additional engineering time.

3. Rework Difficulties: In case of defects, reworking SMT standoffs can be more challenging than traditional through-hole standoffs.

4. Load Bearing Limitations: SMT standoffs may have lower load-bearing capacities compared to some through-hole alternatives.

5. Thermal Considerations: In high-power applications, the thermal properties of SMT connections need careful consideration.

Despite these challenges, the benefits of PCB SMT standoffs often outweigh the limitations for many applications, especially when considering long-term cost savings and performance improvements.

Conclusion

PCB SMT standoffs represent a significant advancement in PCB manufacturing technology, offering substantial potential for cost reduction and performance improvement. By enabling automated installation, improving production efficiency, enhancing quality control, and contributing to material cost savings, these components can play a crucial role in optimizing PCB manufacturing processes.

Moreover, the benefits extend beyond mere cost reduction. PCB SMT standoffs contribute to improved thermal management, mechanical stability, and electrical performance, leading to more reliable and higher-performing electronic products.

As with any technology adoption, successful implementation of PCB SMT standoffs requires careful consideration of design, manufacturing processes, and material selection. However, for many manufacturers, the long-term benefits in terms of cost savings, efficiency improvements, and product quality make the transition to SMT standoffs a worthwhile investment.

As the electronics industry continues to evolve, with increasing demands for miniaturization, performance, and cost-effectiveness, PCB SMT standoffs are likely to play an increasingly important role in PCB manufacturing. By staying informed about these advancements and carefully evaluating their potential benefits, manufacturers can position themselves to remain competitive in an ever-changing market landscape.

Frequently Asked Questions (FAQ)

1. What are the main advantages of using PCB SMT standoffs?

PCB SMT standoffs offer several key advantages:

- Automated installation, reducing labor costs and improving efficiency

- Enhanced mechanical stability for the PCB

- Improved thermal management through better airflow

- Potential for reduced PCB size and material costs

- Compatibility with high-volume SMT manufacturing processes

2. How do PCB SMT standoffs compare to traditional through-hole standoffs?

PCB SMT standoffs differ from traditional through-hole standoffs in several ways:

- Installation method: SMT standoffs are surface-mounted, while through-hole standoffs require holes in the PCB

- Manufacturing process: SMT standoffs can be placed with other SMT components, streamlining production

- Design flexibility: SMT standoffs allow for potentially smaller PCB designs

- Rework considerations: Through-hole standoffs are generally easier to rework, while SMT standoffs may require more specialized techniques

3. Are there any limitations to using PCB SMT standoffs?

While PCB SMT standoffs offer many benefits, they do have some limitations:

- They may have lower load-bearing capacity compared to some through-hole alternatives

- Initial implementation may require investment in new equipment or process changes

- Rework can be more challenging compared to through-hole standoffs

- Design complexity may increase, potentially requiring additional engineering time

4. What factors should be considered when selecting PCB SMT standoffs?

When choosing PCB SMT standoffs, consider the following factors:

- Material properties (electrical conductivity, thermal conductivity, strength)

- Height requirements for your specific application

- Load-bearing requirements

- Thermal management needs

- Compatibility with your existing SMT manufacturing process

- Cost and availability

5. How can PCB SMT standoffs contribute to overall product reliability?

PCB SMT standoffs can enhance product reliability in several ways:

- By providing consistent mechanical support, they reduce the risk of PCB flexing or warping

- Improved thermal management can extend component lifespan

- Automated installation reduces the risk of human error in assembly

- When used in high-frequency applications, they can help maintain signal integrity

- By enabling more compact designs, they can contribute to overall product durability

Citations:

[1] https://www.fivetk.com/e-news/pcb-standoffs/

[2] https://www.pcbcart.com/article/content/smt-process-to-cost-reduction.html

[3] https://www.keyelco.com/category.cfm/Spacers-Standoffs/Standoffs-Spacers-Inserts-Surface-Mount/id/1335

[4] https://etcnmachining.com/?p=16175

[5] https://www.fivetk.com/products/by-solutions/automatic-factory/smt-standoff/

[6] https://sinhoo.en.made-in-china.com/product/ZXgJcszbAprM/China-PCB-Nut-PCB-Standoffs-Weld-Nut-Smtso-M3-6et-Tape-Package-Stock-on-Hand-Steel-Reel.html

[7] https://www.raypcb.com/pcb-standoff/

[8] https://galaxy.weidmueller.com/wi_appguide/CI_img/Whitepaper_SMT_EN.pdf