Content Menu

● Introduction to SMT Stencils

>> Types of SMT Stencils

● Benefits of Framed SMT Stencils

>> Enhanced Accuracy and Consistency

>> Increased Durability

>> Suitability for Automated Processes

>> Cost-Effectiveness in the Long Term

● Applications of Framed SMT Stencils

>> High-Volume Manufacturing

>> Complex PCB Designs

>> Automotive and Aerospace Industries

● Challenges and Future Trends

>> Cost Considerations

>> Technological Advancements

>> Environmental Considerations

● Best Practices for Using Framed SMT Stencils

>> Regular Maintenance

>> Proper Storage

>> Training and Expertise

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary advantages of using framed SMT stencils in PCB assembly?

>> 2. How do framed SMT stencils improve production efficiency?

>> 3. What types of PCBs benefit most from the use of framed SMT stencils?

>> 4. How do framed SMT stencils contribute to cost savings in PCB assembly?

>> 5. What future trends can be expected in the development of framed SMT stencils?

In the realm of electronics manufacturing, Surface Mount Technology (SMT) plays a pivotal role in ensuring efficiency and precision in printed circuit board (PCB) assembly. Central to this process is the SMT stencil, an indispensable tool for the accurate application of solder paste. Among the various types of SMT stencils, framed stencils have emerged as a preferred choice for high-volume manufacturing due to their durability and precision. This article delves into the role of framed SMT stencils in enhancing the PCB assembly process, exploring their benefits, applications, and future trends.

Introduction to SMT Stencils

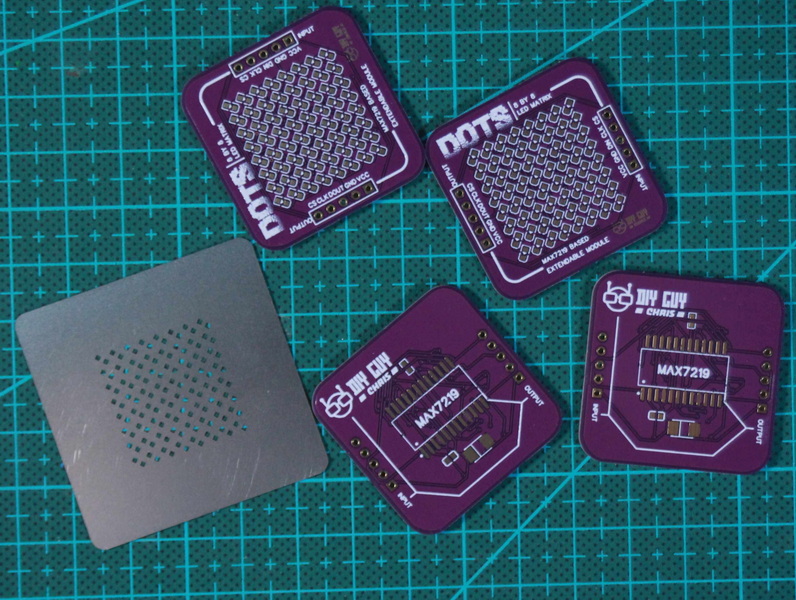

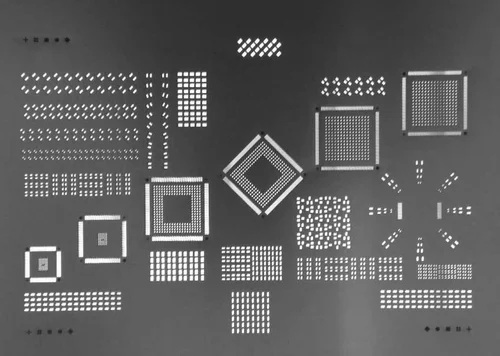

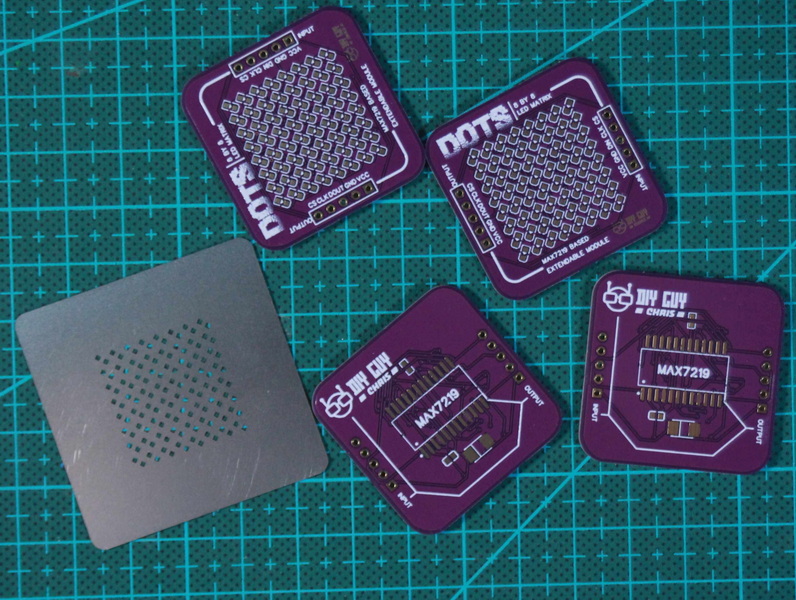

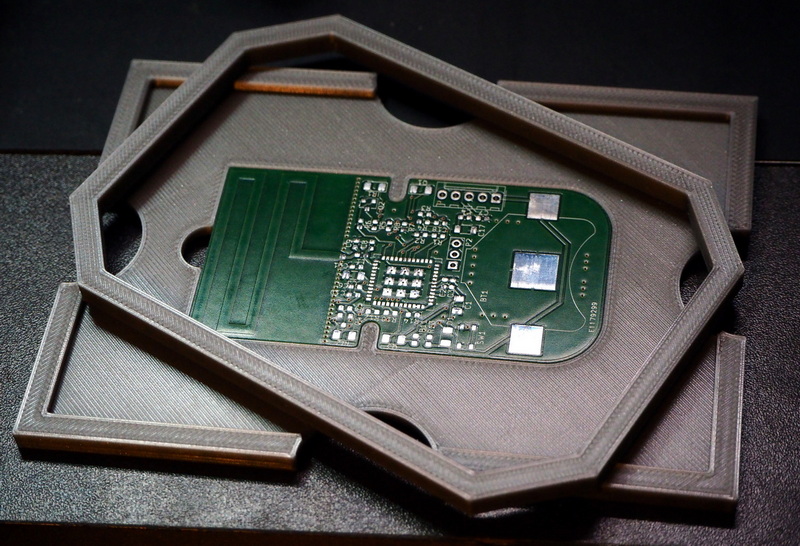

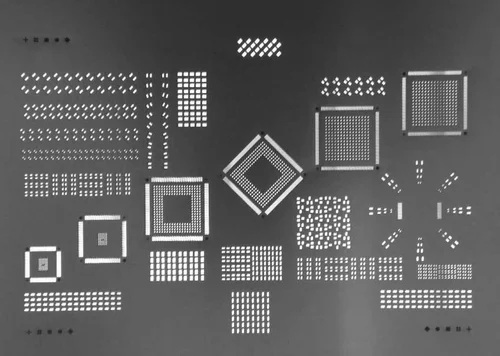

SMT stencils are thin sheets of material, typically made from stainless steel or nickel, with precisely cut apertures that match the layout of components on a PCB. These stencils are used to apply solder paste to the PCB, ensuring that the paste is deposited only where components will be placed. This precise application is crucial for achieving reliable and robust solder joints, which are essential for the functionality and performance of electronic devices.

Types of SMT Stencils

SMT stencils come in several forms, each designed to meet different production needs:

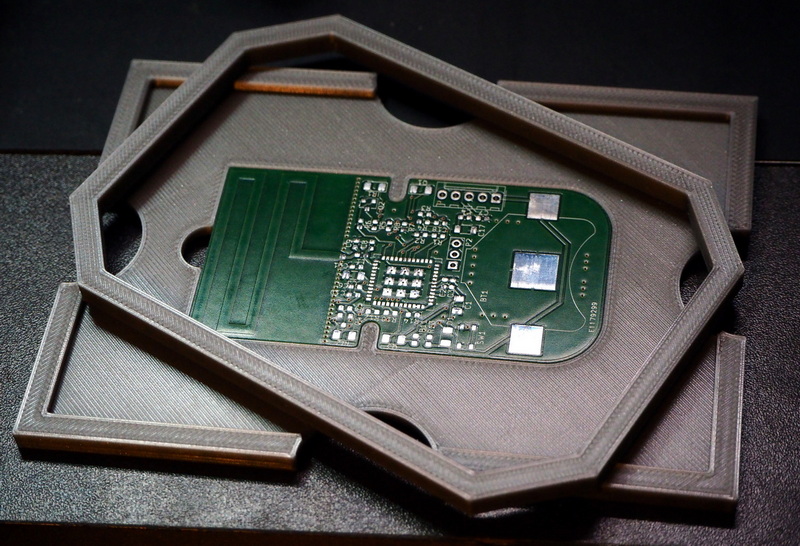

- Framed SMT Stencils: These are mounted onto a frame, providing stability and alignment during the solder paste application process. Framed stencils are ideal for high-volume manufacturing due to their durability and ability to maintain precision across multiple PCBs.

- Frameless SMT Stencils: These are flexible and cost-effective, making them suitable for prototypes and small-scale production. Frameless stencils are easy to handle and store, adapting well to evolving PCB designs.

- Step SMT Stencils: These have different aperture sizes on different levels, allowing for the precise application of varying amounts of solder paste. Step stencils are used for PCBs with components of different sizes and pitches.

Benefits of Framed SMT Stencils

Framed SMT stencils offer several advantages that make them a preferred choice for large-scale PCB assembly:

Enhanced Accuracy and Consistency

The rigid frame of a framed stencil ensures that the stencil remains flat and in position during the printing process. This stability is crucial for maintaining accurate alignment and preventing misalignment issues that can lead to solder bridges or opens. The precision achieved with framed stencils is particularly important for PCBs with fine-pitch components, where even slight misalignments can cause defects.

Increased Durability

Framed stencils are more durable than their frameless counterparts due to the additional support provided by the frame. This durability allows framed stencils to withstand the rigors of high-volume manufacturing, where they may be used for thousands of production cycles without significant wear.

Suitability for Automated Processes

Framed stencils are well-suited for use with automated pick-and-place machines. Their stability and precision make them ideal for mass production lines where consistency and repeatability are essential.

Cost-Effectiveness in the Long Term

Although framed stencils have a higher upfront cost compared to frameless stencils, their durability and ability to minimize defects make them cost-effective in the long term. By reducing the need for rework and minimizing material waste, framed stencils can significantly lower overall production costs.

Applications of Framed SMT Stencils

Framed SMT stencils are widely used in high-volume PCB manufacturing due to their ability to enhance production efficiency and quality:

High-Volume Manufacturing

In high-volume manufacturing environments, framed stencils are preferred for their ability to maintain precision and consistency across large batches of PCBs. Their durability ensures that they can withstand the demands of continuous production without compromising quality.

Complex PCB Designs

For complex PCB designs, especially those with fine-pitch components, framed stencils are essential. They ensure accurate solder paste application, which is critical for achieving reliable solder joints in densely populated boards.

Automotive and Aerospace Industries

In industries such as automotive and aerospace, where reliability and performance are paramount, framed stencils are used extensively. The precision and consistency they provide are crucial for ensuring that electronic components meet stringent quality standards.

Challenges and Future Trends

While framed SMT stencils offer numerous benefits, there are also challenges and considerations for future developments:

Cost Considerations

One of the primary drawbacks of framed stencils is their higher cost compared to frameless stencils. The additional material and labor required to manufacture the frame contribute to this increased expense. However, as discussed earlier, their long-term cost-effectiveness can offset this initial investment.

Technological Advancements

As PCB technology continues to evolve, SMT stencils must adapt to support advancements such as miniaturization and increased functionality. Future stencils will need to be designed to accommodate smaller components and more complex layouts while maintaining precision and efficiency.

Environmental Considerations

The electronics industry is increasingly focused on sustainability and reducing environmental impact. Future developments in framed SMT stencils may include materials and manufacturing processes that are more environmentally friendly, such as recyclable materials or reduced waste production.

Best Practices for Using Framed SMT Stencils

To maximize the benefits of framed SMT stencils, several best practices should be followed:

Regular Maintenance

Regular cleaning and maintenance of framed stencils are crucial to ensure they remain effective. This includes removing solder paste residue and inspecting for wear or damage.

Proper Storage

Framed stencils should be stored in a clean, dry environment to prevent corrosion or damage. This helps extend their lifespan and maintain their precision.

Training and Expertise

Operators should be well-trained in the use of framed stencils to ensure that they are used correctly and efficiently. This includes understanding how to align the stencil properly and apply the correct amount of solder paste.

Conclusion

Framed SMT stencils play a crucial role in enhancing the PCB assembly process by providing precision, consistency, and durability. Their ability to support high-volume manufacturing while minimizing defects makes them an indispensable tool in modern electronics production. As technology advances, the importance of framed SMT stencils will continue to grow, enabling the efficient assembly of complex electronic devices.

Frequently Asked Questions

1. What are the primary advantages of using framed SMT stencils in PCB assembly?

Framed SMT stencils offer enhanced accuracy and consistency in solder paste application, increased durability, and suitability for automated processes. These advantages make them ideal for high-volume manufacturing and complex PCB designs.

2. How do framed SMT stencils improve production efficiency?

Framed stencils improve production efficiency by enabling simultaneous solder paste application across multiple PCBs, reducing assembly time, and increasing production throughput. Their precision also minimizes defects, reducing rework costs.

3. What types of PCBs benefit most from the use of framed SMT stencils?

PCBs with fine-pitch components or complex designs benefit significantly from framed stencils. The precision and consistency provided by these stencils are crucial for achieving reliable solder joints in densely populated boards.

4. How do framed SMT stencils contribute to cost savings in PCB assembly?

Framed stencils contribute to cost savings by minimizing material waste and reducing the need for rework or repairs. Their precision ensures that the correct amount of solder paste is applied, reducing waste and enhancing profitability.

5. What future trends can be expected in the development of framed SMT stencils?

Future trends in framed SMT stencils will focus on adapting to technological advancements such as miniaturization and increased functionality. Stencils will need to accommodate smaller components and more complex layouts while maintaining precision and efficiency.