Content Menu

● Understanding SMD Tape Machines

● Flexibility in Handling Different Component Sizes

>> Standard Tape Widths and Pocket Sizes

>> Dimensional Tolerances and Precision

>> Customization and Adaptability

>> Handling Odd-Shaped and Non-Standard Components

● Technical Specifications Influencing Size Handling

● Benefits of Using an SMD Tape Machine for Various Component Sizes

● Challenges and Considerations

● Best Practices for Using an SMD Tape Machine with Different Component Sizes

● Future Trends in SMD Tape Machines and Component Size Handling

● Conclusion

● FAQ

>> 1. What range of component sizes can an SMD tape machine handle?

>> 2. How does an SMD tape machine accommodate very small components?

>> 3. Can an SMD tape machine be customized for special component sizes?

>> 4. What sealing methods are used in SMD tape machines?

>> 5. Are there limitations on reel size for SMD tape machines?

Surface Mount Device (SMD) tape machines are critical equipment in modern electronics manufacturing, designed to package electronic components efficiently and reliably for automated assembly lines. One common question in the electronics production industry is whether an SMD tape machine can handle different component sizes. This article explores the capabilities, flexibility, and technical considerations of SMD tape machines in managing various component sizes, highlighting their importance in enhancing production efficiency and product quality.

Understanding SMD Tape Machines

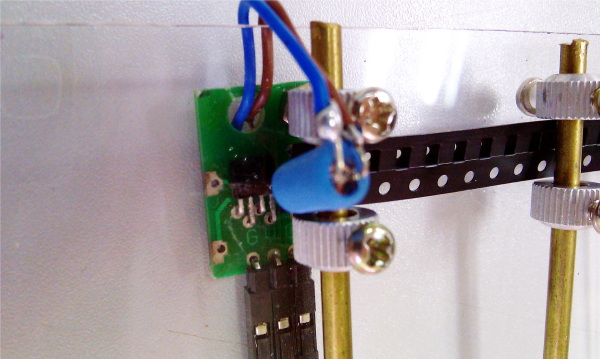

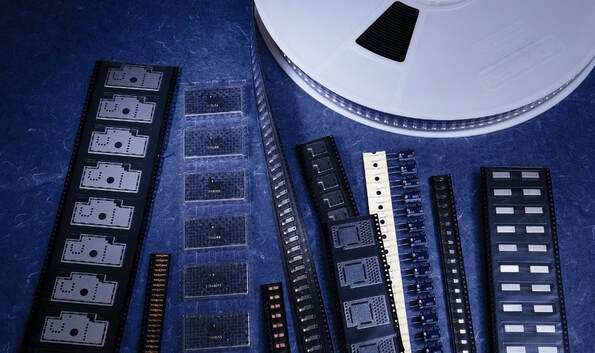

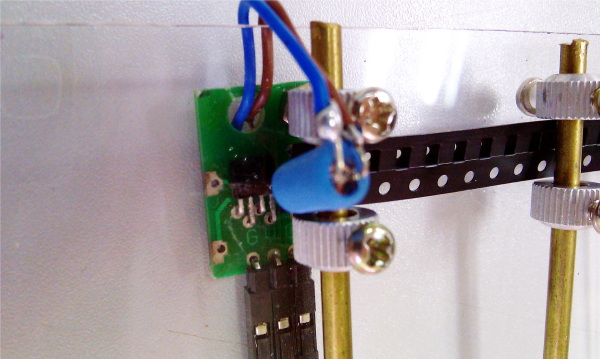

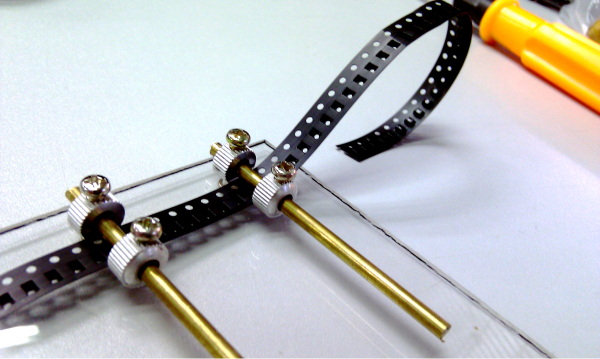

An SMD tape machine automates the process of packaging surface mount components into carrier tapes sealed with cover tapes, forming reels that are compatible with pick-and-place machines. These machines are engineered to handle components ranging from small resistors and capacitors to larger inductors and integrated circuits, packaging them in standardized tape formats for efficient feeding during assembly.

The machine typically performs several functions:

- Automatic feeding of components into carrier tape pockets

- Sealing the carrier tape with cover tape using heat or adhesive methods

- Cutting and furling the tape into reels

- Optional electrical testing and visual inspection of components during packaging

These functions ensure components are securely packaged, protected from damage and static discharge, and ready for high-speed automated placement.

Flexibility in Handling Different Component Sizes

Standard Tape Widths and Pocket Sizes

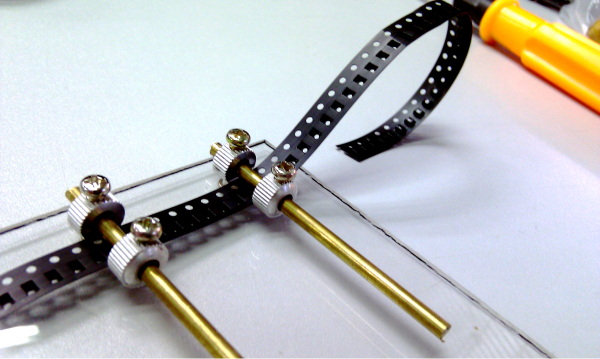

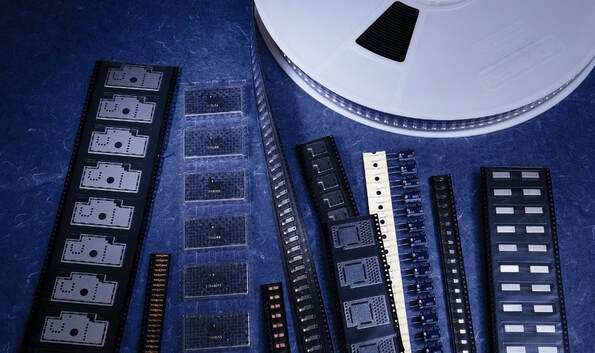

SMD tape machines are designed to accommodate a range of carrier tape widths and pocket sizes. Common carrier tape widths include 4mm, 8mm, 12mm, 16mm, 24mm, 32mm, 44mm, and 56mm. The pocket size within the tape is tailored to the specific dimensions of the component to ensure proper fit and protection during handling.

The machine's ability to handle different sizes depends on:

- The width of the tape it can process

- The pocket dimensions and tolerances of the carrier tape

- The sealing mechanism's adaptability to different tape thicknesses and cover tapes

For example, some machines support carrier tapes with widths from 8mm up to 88mm or even 96mm for larger components, with customization options available for special sizes.

Dimensional Tolerances and Precision

As component sizes decrease, the dimensional tolerances of the carrier tape pockets become increasingly critical. Smaller components require tighter tolerances to prevent rotation, tilt, or misalignment within the tape pockets, which could cause placement errors during assembly.

High-precision carrier tapes with tolerances as tight as 30 micrometers may be necessary for very small devices such as leadless wafer-level chip scale packages. SMD tape machines must be compatible with these precision tapes and capable of handling the delicate components without damage.

Customization and Adaptability

Modern SMD tape machines often offer customization options to handle various component types and sizes. Feeding modes can be adapted to use pallet feeding, vibrating disc feeding, or belt feeding depending on the component form factor and production requirements. The sealing and cutting mechanisms can be adjusted for different tape and cover tape materials, ensuring secure packaging regardless of component size.

Some machines also allow for manual loading of components for non-standard sizes or special orders, while maintaining automated sealing and furling processes to ensure efficiency.

Handling Odd-Shaped and Non-Standard Components

In addition to standard rectangular or cylindrical components, some SMD tape machines can be configured to handle oddly shaped or irregular components. This capability is particularly important for newer or specialized components that do not conform to traditional packaging standards. Through adjustable pocket sizes, custom carrier tapes, and specialized feeding systems, these machines can package a wide variety of components, enhancing the versatility of the production line.

Technical Specifications Influencing Size Handling

Several technical aspects of an SMD tape machine influence its capability to handle different component sizes:

- Tape Width Compatibility: Machines specify a range of tape widths they can process, which correlates with the maximum component width they can package.

- Sealing Types: Heat sealing and self-adhesive sealing methods can accommodate different cover tape materials and thicknesses.

- Feeding Speed and Capacity: Machines can adjust speed to match component loading rates, which may vary with component size and complexity.

- Machine Size and Power: Larger machines with higher power consumption typically handle bigger or more complex components and tapes.

- Environmental Conditions: Machines operate within specified temperature and humidity ranges to ensure component integrity during packaging.

- Component Height and Thickness Limits: Some SMD tape machines specify maximum component height and thickness that can be accommodated within the carrier tape pockets and under the cover tape.

Benefits of Using an SMD Tape Machine for Various Component Sizes

- Increased Production Efficiency: Automating the packaging process for different component sizes reduces manual labor and speeds up production lines.

- Improved Compatibility: Standardized tape and reel packaging ensures seamless integration with pick-and-place machines regardless of component size.

- Reduced Errors and Damage: Precise pocket dimensions and secure sealing protect components from damage and misplacement.

- Customization: Flexibility to package a wide range of component sizes supports diverse manufacturing needs and product lines.

- Enhanced Logistics: Tape and reel packaging simplifies inventory management and transportation of components in bulk.

- Improved Traceability: Many SMD tape machines include options for labeling and barcoding reels, which helps in tracking components by size, batch, and production date.

Challenges and Considerations

While SMD tape machines are versatile, certain challenges exist when handling different component sizes:

- Small Components: Require high-precision tapes and careful handling to avoid misalignment or damage. The risk of component loss or jamming increases with smaller sizes.

- Large Components: Need wider tapes and stronger sealing mechanisms, which may require machine customization. Larger components may also affect tape reel size and handling logistics.

- Non-Standard Components: May need manual loading or special feeding systems. Custom carrier tapes may increase production costs and lead times.

- Machine Limitations: Some machines have maximum tape width or reel diameter limits that restrict the size range they can handle.

- Material Compatibility: Different components may require special carrier tape materials or cover tape adhesives to prevent damage or contamination.

- Setup Time: Changing between different component sizes often requires machine adjustments and setup time, which can impact production efficiency if not managed properly.

Best Practices for Using an SMD Tape Machine with Different Component Sizes

To maximize the capability of an SMD tape machine in handling different component sizes, manufacturers should consider the following best practices:

- Choose the Right Machine: Select an SMD tape machine model that supports the widest range of tape widths and pocket sizes needed for your product range.

- Use Standardized Carrier Tapes: Whenever possible, use industry-standard carrier tapes to ensure compatibility and reduce tooling costs.

- Maintain Precision: Regularly calibrate and maintain the machine to ensure pocket alignment and sealing accuracy, especially when switching between small and large components.

- Train Operators: Skilled operators can efficiently manage setup changes and troubleshoot issues related to different component sizes.

- Implement Quality Control: Integrate inspection systems to verify component placement and tape sealing quality, minimizing errors.

- Plan Production Runs: Group components by size or tape width to minimize frequent machine adjustments and improve throughput.

- Leverage Customization: Work with machine suppliers to customize feeding, sealing, and cutting mechanisms for unique component sizes or shapes.

Future Trends in SMD Tape Machines and Component Size Handling

The electronics industry continues to evolve, with components becoming smaller, more complex, and more diverse. SMD tape machines are also advancing to meet these challenges:

- Increased Automation: Integration with smart factory systems allows for automatic adjustment of machine parameters based on component size data.

- Advanced Materials: Development of new carrier tape and cover tape materials that better protect sensitive components.

- Enhanced Precision: Improved mechanical designs and sensors enable handling of ultra-small components with greater reliability.

- Modular Designs: Machines with modular components that can be quickly swapped to accommodate different tape widths and pocket sizes.

- Data Integration: Real-time monitoring and data analytics help optimize packaging processes for different component sizes.

These innovations will further enhance the flexibility and efficiency of SMD tape machines in handling a broad spectrum of component sizes.

Conclusion

SMD tape machines are highly capable of handling different component sizes due to their flexible design, customizable feeding modes, and compatibility with a wide range of carrier tape widths and pocket dimensions. They play a vital role in modern electronics manufacturing by ensuring efficient, precise, and reliable packaging of surface mount components. With the ability to adapt to various sizes-from tiny chip resistors to larger inductors and ICs-these machines enhance production efficiency, reduce errors, and improve product quality. Selecting the right SMD tape machine and optimizing its setup according to component specifications is key to maximizing its benefits in diverse manufacturing environments.

By understanding the technical specifications, customization options, and best practices, manufacturers can effectively use SMD tape machines to handle a wide variety of component sizes, supporting both standard and specialized production needs. As technology advances, the adaptability and precision of these machines will continue to grow, meeting the evolving demands of the electronics industry.

FAQ

1. What range of component sizes can an SMD tape machine handle?

An SMD tape machine can typically handle component widths from around 4mm up to 88mm or more, depending on the machine model and customization options. Tape widths commonly range from 4mm to 56mm or wider for larger components, with pocket sizes tailored accordingly.

2. How does an SMD tape machine accommodate very small components?

For very small components, the machine uses high-precision carrier tapes with tight pocket tolerances to prevent component rotation or misalignment. The feeding and sealing processes are carefully controlled to handle delicate parts without damage, often requiring specialized feeding systems.

3. Can an SMD tape machine be customized for special component sizes?

Yes, many SMD tape machines offer customization in feeding modes, tape widths, sealing methods, and other parameters to accommodate non-standard or larger component sizes. Custom carrier tapes and adjustable mechanisms enable packaging of unique components.

4. What sealing methods are used in SMD tape machines?

Common sealing methods include heat sealing and self-adhesive sealing of the cover tape. Machines may support both methods to suit different tape materials and component protection requirements, ensuring secure packaging.

5. Are there limitations on reel size for SMD tape machines?

Some machines have maximum reel diameter limits, often supporting standard sizes like 7-inch or 13-inch reels. Selecting the correct reel size is important to avoid machine downtime and ensure smooth operation, especially for larger components requiring wider tapes.