Content Menu

● Introduction to SMD Rework Machines

>> Key Features of SMD Rework Machines

● Handling Different Types of Components

● Techniques for Effective Rework

● Choosing the Right SMD Rework Machine

● Advanced Features in Modern SMD Rework Machines

● Applications in Electronics Manufacturing

● Challenges and Solutions

● Conclusion

● FAQs

>> 1. What types of components can an SMD rework machine handle?

>> 2. What are the key features to look for in an SMD rework machine?

>> 3. How do I ensure effective rework with an SMD rework machine?

>> 4. What are the benefits of using a high-quality SMD rework machine?

>> 5. How do I choose the right SMD rework machine for my needs?

● Citations:

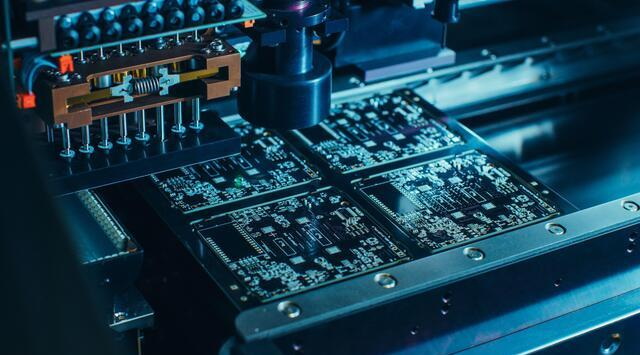

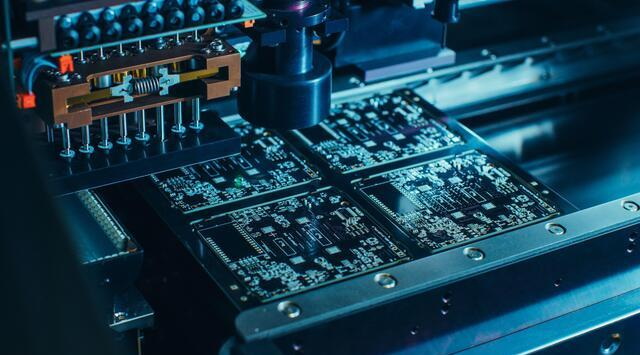

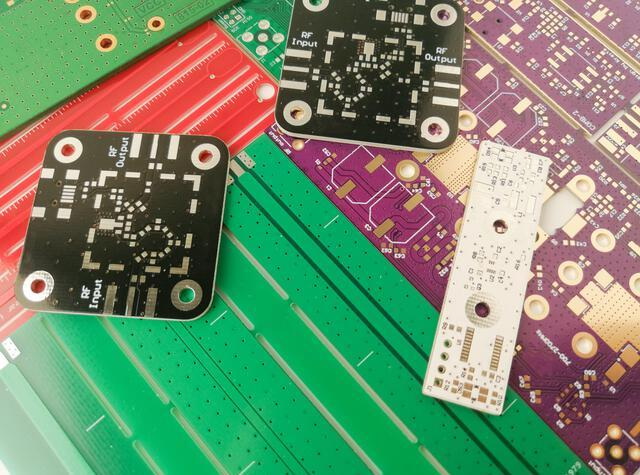

In the realm of electronics manufacturing and repair, Surface Mount Device (SMD) rework machines play a crucial role in handling and repairing delicate components on printed circuit boards (PCBs). These machines are designed to efficiently manage the desoldering and resoldering of SMD components, which are integral to modern electronic devices due to their compact size and high performance. The question arises: Can an SMD rework machine handle different types of components? This article delves into the capabilities of SMD rework machines, their versatility, and the variety of components they can manage.

Introduction to SMD Rework Machines

SMD rework machines are specialized tools used for the precise removal and replacement of surface-mounted components on PCBs. These machines typically include features such as temperature-controlled hot air rework tools, soldering irons, and preheating platforms. The hot air tool is essential for heating solder joints to facilitate component removal and reattachment, while the soldering iron is used for localized soldering and desoldering tasks. Preheating platforms help to evenly warm the PCB, reducing thermal stress during the rework process.

Key Features of SMD Rework Machines

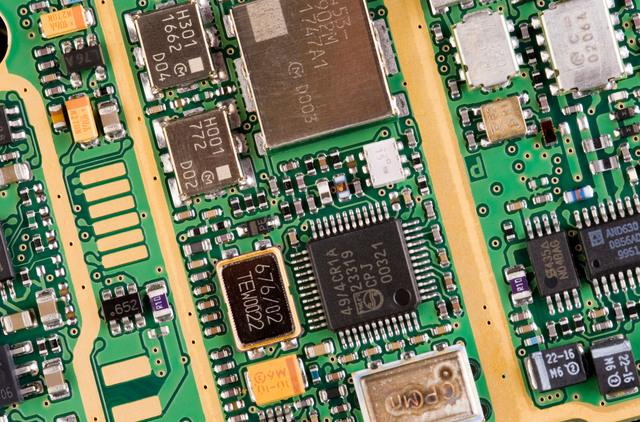

1. Temperature and Airflow Control: These machines offer precise control over temperature and airflow, allowing technicians to adjust settings according to the type of component being reworked. This feature is crucial for preventing overheating or underheating, which can damage components or the PCB.

2. Multi-Tool Functionality: Advanced SMD rework machines often include multiple tools such as soldering irons, hot air guns, and desoldering tools, making them versatile for various rework tasks.

3. Ergonomic Design: Designed for comfort, these machines reduce user fatigue and promote prolonged productivity, which is essential in high-volume repair environments.

4. Quick Heat-Up Time: A fast heat-up time ensures that technicians can work efficiently, minimizing downtime and increasing productivity.

5. Compatibility with Various Components: High-quality SMD rework machines are capable of handling a wide range of components, from small SMDs like resistors and capacitors to more complex components like Ball Grid Arrays (BGAs) and fine-pitch ICs.

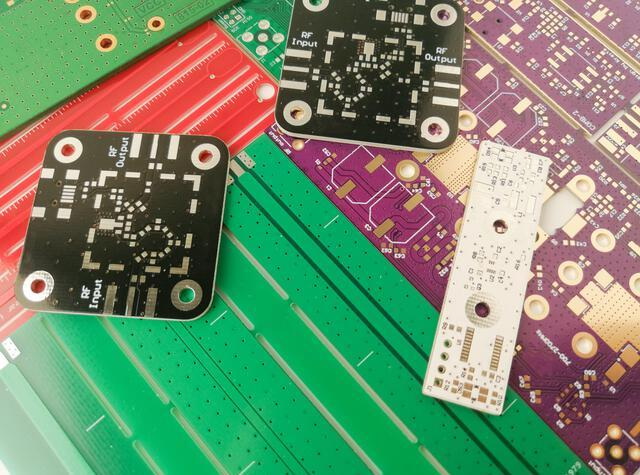

Handling Different Types of Components

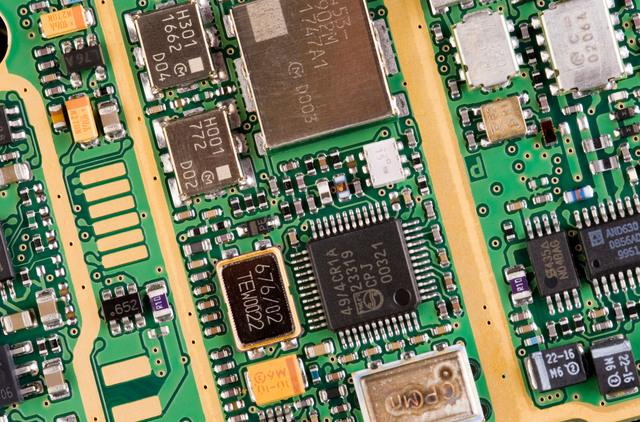

SMD rework machines are designed to handle a variety of components, including:

- SMD Resistors and Capacitors: These are common components found in most electronic devices. SMD rework machines can easily desolder and resolder these components using hot air tools or soldering irons.

- BGAs (Ball Grid Arrays): BGAs are complex components with numerous solder balls underneath. SMD rework machines equipped with advanced hot air tools can manage these components by providing controlled heat to melt the solder balls without damaging the component or the PCB.

- Fine-Pitch ICs: These components have closely spaced leads and require precise temperature control to avoid damaging the leads or the PCB. SMD rework machines with adjustable temperature settings are ideal for handling such components.

- LEDs and Other SMD Components: LEDs, inductors, and transformers are also commonly reworked using SMD rework machines. These machines ensure that these components are securely soldered onto the PCB without causing thermal stress.

Techniques for Effective Rework

To effectively rework different types of components, technicians must employ precise techniques:

1. Preheating: Preheating the PCB helps to prevent thermal shock and ensures that the solder melts evenly, making it easier to remove or replace components.

2. Temperature Control: Maintaining the correct temperature is crucial. Too much heat can damage components, while insufficient heat may result in poor solder joints.

3. Airflow Management: Adjusting airflow is important to prevent overheating or underheating. Proper airflow ensures that solder melts consistently and components are not damaged.

4. Component Alignment: Carefully aligning components before soldering is essential to ensure proper electrical connections and prevent mechanical stress on the PCB.

5. Inspection: Using magnification tools to inspect solder joints after rework ensures that they are well-formed and free of defects.

Choosing the Right SMD Rework Machine

When selecting an SMD rework machine, several factors should be considered:

1. Component Compatibility: Ensure the machine can handle the types of components you work with most frequently.

2. Precision and Control: Look for machines with precise temperature and airflow control to minimize the risk of component damage.

3. Ergonomics and Design: Choose a machine that is comfortable to use and reduces fatigue.

4. Brand and Support: Consider reputable brands that offer reliable support and maintenance services.

5. Cost and Value: Assess the cost in relation to the features and performance offered by the machine.

Advanced Features in Modern SMD Rework Machines

Modern SMD rework machines often incorporate advanced technologies to enhance their capabilities:

- Machine Vision Technology: Some high-end machines, like the AT-GDP SMD and BGA rework station, utilize machine vision to accurately place and align components, ensuring precise soldering and minimizing human error[6].

- Automated Profile Generation: Advanced software allows users to create and save custom temperature profiles for different components, streamlining the rework process and improving consistency[6].

- Closed-Loop Reflow Process Control: This feature enables precise control over the reflow process, mimicking the original production conditions to ensure high-quality solder joints[6].

Applications in Electronics Manufacturing

SMD rework machines are essential in various stages of electronics manufacturing:

1. Repair and Maintenance: They are used to repair faulty components without damaging the surrounding circuitry, extending the lifespan of electronic devices and reducing waste[4].

2. Prototype Development: These machines are invaluable in the prototyping phase, allowing for quick and precise adjustments to PCBs during the design process[6].

3. Quality Control: SMD rework machines help in inspecting and correcting defects in PCBs before they are shipped out, ensuring high-quality products reach the market[2].

Challenges and Solutions

Despite their versatility, SMD rework machines present some challenges:

1. Component Sensitivity: Some components are highly sensitive to heat and require precise temperature control to prevent damage. Advanced machines with adjustable temperature settings address this issue[4].

2. Operator Skill: Effective use of SMD rework machines requires skilled technicians who understand the nuances of temperature control and component handling. Training programs can help bridge this gap[3].

3. Equipment Maintenance: Regular maintenance of the machine's tools, such as cleaning soldering tips and nozzles, is crucial for maintaining performance and preventing damage to components[3].

Conclusion

SMD rework machines are highly versatile tools capable of handling a wide range of components, from simple SMDs to complex BGAs. Their ability to provide precise temperature and airflow control makes them essential for modern electronics repair and manufacturing. By understanding the capabilities and features of these machines, technicians can optimize their workflow and ensure high-quality repairs.

FAQs

1. What types of components can an SMD rework machine handle?

An SMD rework machine can handle various components, including SMD resistors, capacitors, BGAs, fine-pitch ICs, LEDs, and more. These machines are designed to provide precise control over temperature and airflow, making them suitable for a wide range of components.

2. What are the key features to look for in an SMD rework machine?

Key features include temperature and airflow control, multi-tool functionality, ergonomic design, quick heat-up time, and compatibility with various components.

3. How do I ensure effective rework with an SMD rework machine?

Effective rework involves preheating the PCB, maintaining precise temperature control, managing airflow, aligning components carefully, and inspecting solder joints after rework.

4. What are the benefits of using a high-quality SMD rework machine?

High-quality SMD rework machines offer enhanced precision, increased efficiency, long-term cost savings, and improved workflow. They minimize component damage and reduce repair costs.

5. How do I choose the right SMD rework machine for my needs?

Consider factors such as component compatibility, precision and control, ergonomic design, brand reputation, and cost in relation to performance when selecting an SMD rework machine.

Citations:

[1] https://scanditronictech.com/resources/smd-soldering-rework-stations/

[2] https://www.aixuntech.com/newsinfo/the-many-uses-of-rework-station-in-electronics-manufacturing/

[3] https://rework.co.uk/blog/basics-of-smd-rework/

[4] https://www.aixuntech.com/newsinfo/smd-rework-station-comprehensive-guide-for-beginner/

[5] https://finetechusa.com/rework-equipment/

[6] https://www.atco-us.com/at-gdp-smd-bga-placement-rework-stations/

[7] https://www.qsource.com/blog/669/what-is-an-smd-rework-station-hot-air-soldering-explained

[8] https://www.youtube.com/watch?v=CORLzDxDV4w

[9] https://www.seamarkzm.com/features-and-functionality-of-laser-smd-rework-stations.html

[10] https://www.reddit.com/r/soldering/comments/s4vi3r/do_i_really_need_smd_rework_station/

[11] https://www.youtube.com/watch?v=v58m-S35s24

[12] https://paceworldwide.com/tf1800-bga-and-smd-rework-system

[13] https://forum.arduino.cc/t/what-smd-equipment-do-i-need/1115548

[14] https://www.instructables.com/SMD-SOLDERING-101-USING-HOT-PLATE-HOT-AIR-BLOWER-S/

[15] https://paceworldwide.com/tf2800-bga-and-smd-rework-system

[16] https://www.edaboard.com/threads/entering-the-field-of-smd-reworking-smd-rework-stations-propositions.320931/

[17] https://www.reddit.com/r/AskElectronics/comments/p60mps/looking_for_a_guide_to_diy_smd_soldering/

[18] https://sumitron.com/choosing-the-best-smd-rework-station-for-precision-repairs-rework/

[19] https://electronics.stackexchange.com/questions/24603/what-to-look-for-in-desoldering-rework-equipment

[20] https://www.youtube.com/watch?v=fYInlAmPnGo