Content Menu

● Understanding SMD Reflow Machines

>> Key Components of an SMD Reflow Machine

● How SMD Reflow Machines Reduce Production Costs

>> 1. Increased Production Efficiency

>> 2. Consistency and Reliability

>> 3. Lower Maintenance and Operating Costs

>> 4. Flexibility with Leaded and Lead-Free Solder

>> 5. Space and Material Savings

● Additional Benefits of Using an SMD Reflow Machine

>> Improved Quality Control

>> Scalability

>> Reduced Environmental Impact

● Choosing the Right SMD Reflow Machine for Cost Reduction

● Conclusion

● FAQ

>> 1. What is an SMD reflow machine, and how does it work?

>> 2. How does using an SMD reflow machine improve production efficiency?

>> 3. Can an SMD reflow machine handle both leaded and lead-free solder?

>> 4. What are the maintenance advantages of modern SMD reflow machines?

>> 5. How does an SMD reflow machine contribute to environmental sustainability?

In the fast-paced world of electronics manufacturing, cost efficiency and product quality are crucial for competitiveness. Surface-mount device (SMD) technology has revolutionized electronics assembly, enabling miniaturization and higher circuit density. Central to this process is the SMD reflow machine, a device designed to solder surface-mount components onto printed circuit boards (PCBs) through controlled heating. This article explores how an SMD reflow machine can help reduce production costs in electronics manufacturing by enhancing efficiency, consistency, and reliability.

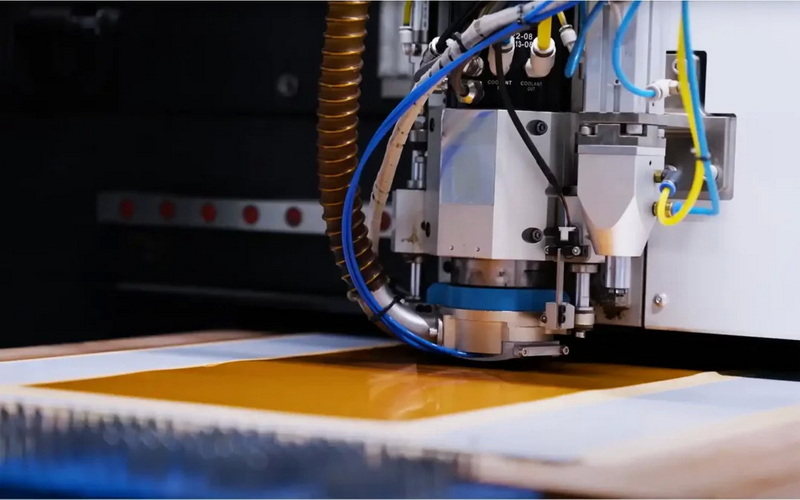

Understanding SMD Reflow Machines

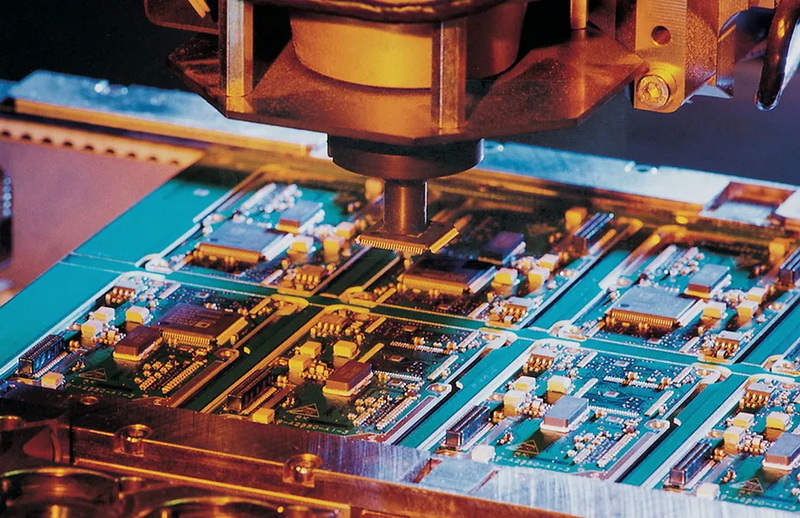

An SMD reflow machine is a specialized oven that heats PCBs with solder paste and surface-mount components to a precise temperature profile. This melts the solder paste, allowing components to bond securely to the PCB. The process is carefully controlled to avoid defects such as solder bridging, cold joints, or component damage.

Reflow soldering is distinct from traditional soldering methods like wave soldering, as it is optimized for surface-mount technology (SMT), which supports smaller, more densely packed components. The reflow machine typically features multiple heating zones, including preheat, soak, reflow, and cooling stages, to ensure optimal solder joint quality.

Key Components of an SMD Reflow Machine

- Heating Zones: These zones gradually raise the temperature of the PCB to melt the solder paste without damaging components.

- Conveyor System: Moves PCBs through the oven at a controlled speed.

- Temperature Sensors: Monitor and adjust the temperature in real-time to maintain the desired profile.

- Nitrogen Atmosphere System (optional): Some machines use nitrogen to reduce oxidation during soldering, improving joint quality.

How SMD Reflow Machines Reduce Production Costs

1. Increased Production Efficiency

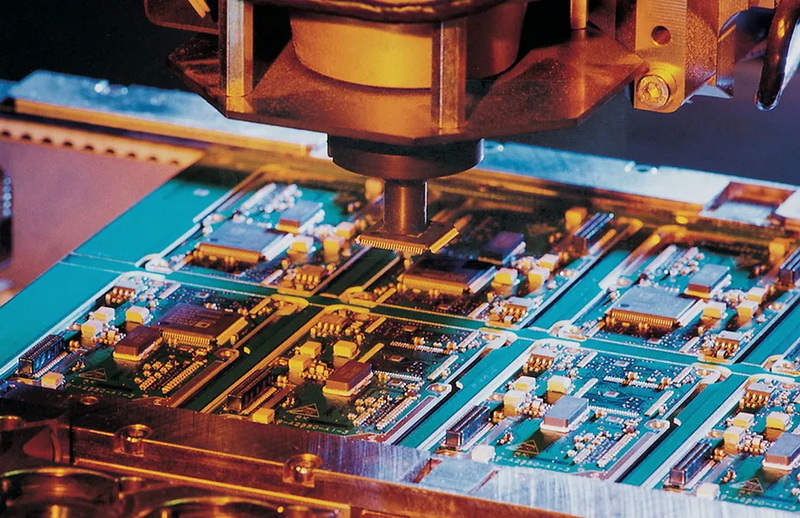

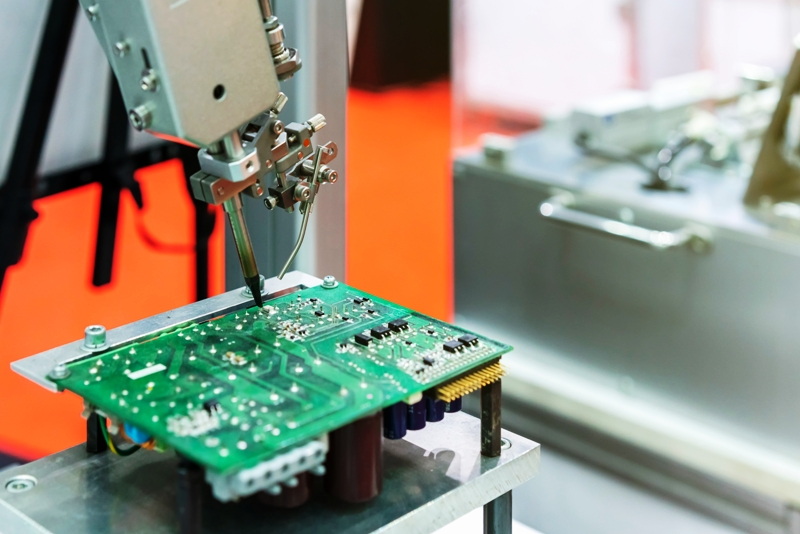

Automated SMD reflow machines significantly boost production throughput. They can handle large volumes of PCBs with minimal human intervention, reducing labor costs and human error. The automation ensures consistent solder paste melting and component attachment, which minimizes rework and scrap rates.

In manual soldering or less automated processes, variability in temperature and timing can cause defects that require costly repairs or lead to product rejection. By contrast, an SMD reflow machine follows a programmed temperature profile precisely, ensuring every board is processed uniformly.

2. Consistency and Reliability

The precise temperature control in an SMD reflow machine ensures uniform solder joints across all PCBs. This consistency reduces the likelihood of defects that can cause product failures or returns, which are costly for manufacturers. Reliable soldering also extends product lifespan and customer satisfaction, indirectly reducing warranty and repair expenses.

Moreover, consistent soldering quality minimizes the need for extensive quality control inspections, saving time and labor costs. The ability to reproduce the same high-quality results batch after batch is invaluable in large-scale electronics manufacturing.

3. Lower Maintenance and Operating Costs

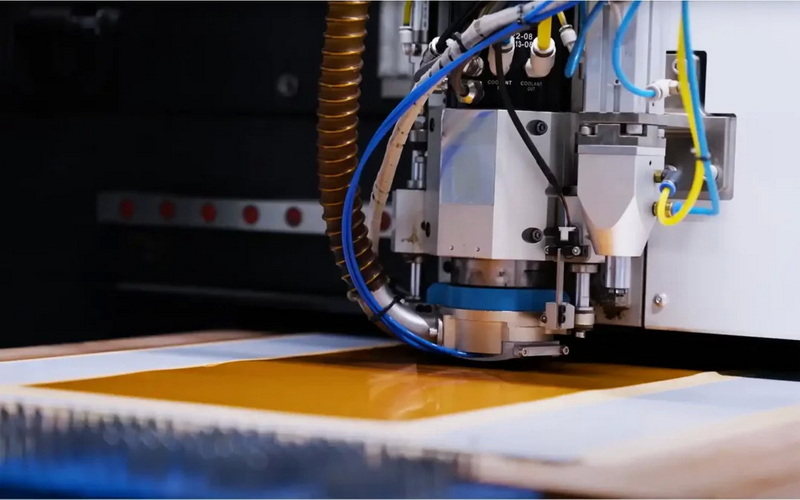

Modern SMD reflow machines incorporate technological advances that reduce maintenance needs and operating expenses. For example, innovations like self-cleaning modes and flux management systems reduce downtime and the need for manual cleaning. Flux residue, if not properly managed, can cause defects or require frequent cleaning, which interrupts production.

Energy-saving features, such as SmartPower and EnergyPilot software, optimize power consumption and reduce nitrogen gas usage, a common inert atmosphere used in reflow ovens to improve solder quality. These features not only reduce utility bills but also extend the lifespan of heating elements and other components, lowering replacement costs.

4. Flexibility with Leaded and Lead-Free Solder

SMD reflow machines can be calibrated to work with both leaded and lead-free solder pastes. Leaded solder has a lower melting point and is easier to process, while lead-free solder is environmentally friendly and often mandated by regulations such as RoHS (Restriction of Hazardous Substances).

The ability to handle mixed assemblies without compromising quality reduces the need for different machines or processes, saving capital and operational costs. Manufacturers can switch between solder types depending on product requirements without significant downtime or retooling.

5. Space and Material Savings

Reflow soldering enables the use of smaller surface-mount components, which take up less space on PCBs. This miniaturization allows manufacturers to design more compact devices or fit more functionality into the same footprint, potentially reducing material costs.

Additionally, precise solder paste application minimizes waste, further lowering material expenses. Unlike through-hole soldering, which requires more solder and larger holes, surface-mount technology combined with reflow soldering uses solder paste applied in controlled amounts, reducing excess solder and associated costs.

Additional Benefits of Using an SMD Reflow Machine

Improved Quality Control

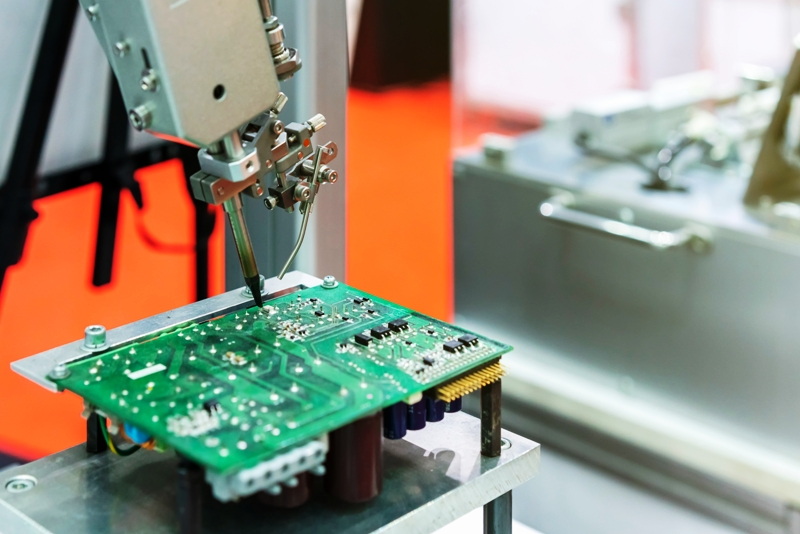

Automated profiling and monitoring systems ensure that each PCB passes through the exact temperature curve required, improving yield rates. Many modern machines include real-time data logging and feedback systems, allowing operators to detect and correct process deviations immediately.

This level of control reduces the risk of latent defects that might only appear after product deployment, which can be costly in terms of recalls and brand reputation damage.

Scalability

SMD reflow machines are suitable for both small batch and high-volume production, allowing manufacturers to scale operations without significant additional investment. This flexibility means companies can respond quickly to market demand changes without compromising quality or increasing costs disproportionately.

Reduced Environmental Impact

By enabling lead-free soldering and reducing nitrogen consumption, modern reflow machines contribute to greener manufacturing practices. The reduction of hazardous materials and energy-efficient operation aligns with global sustainability goals and regulatory requirements, potentially opening new markets and customer segments.

Choosing the Right SMD Reflow Machine for Cost Reduction

To maximize cost savings, manufacturers should consider several factors when selecting an SMD reflow machine:

- Throughput Requirements: Machines vary in size and conveyor speed; selecting one that matches production volume avoids under- or over-investment.

- Temperature Control Precision: Higher precision reduces defects and rework.

- Energy Efficiency: Features that reduce power and gas consumption lower operating costs.

- Maintenance Features: Self-cleaning and easy access for repairs reduce downtime.

- Software and Automation: Advanced profiling and monitoring improve process control and traceability.

Investing in a high-quality SMD reflow machine with these features can deliver significant long-term savings despite higher upfront costs.

Conclusion

An SMD reflow machine is a critical asset in modern electronics manufacturing that can substantially reduce production costs. Through automation, precise temperature control, and advanced features that lower maintenance and energy consumption, these machines improve efficiency and product quality. Their flexibility in handling various solder types and support for miniaturized components further contribute to cost savings.

Additionally, the reduction in defects, rework, and scrap rates, combined with lower labor and material costs, makes the SMD reflow machine an indispensable tool for competitive electronics production. Ultimately, investing in a high-quality SMD reflow machine helps manufacturers achieve reliable, scalable, and environmentally responsible production, making it a smart choice for reducing overall electronics manufacturing expenses.

FAQ

1. What is an SMD reflow machine, and how does it work?

An SMD reflow machine is an oven used to solder surface-mount components onto PCBs by heating solder paste to its melting point. It uses controlled temperature zones to ensure the solder melts and solidifies properly, creating strong, reliable joints.

2. How does using an SMD reflow machine improve production efficiency?

By automating the soldering process, SMD reflow machines reduce manual labor and human error, increase throughput, and ensure consistent quality, which lowers rework and scrap rates.

3. Can an SMD reflow machine handle both leaded and lead-free solder?

Yes, many SMD reflow machines can be programmed to work with both leaded solder, which has a lower melting point and is easier to process, and lead-free solder, which is environmentally safer and often required by regulations.

4. What are the maintenance advantages of modern SMD reflow machines?

Modern machines feature self-cleaning modes, flux management systems, and energy-saving software that reduce downtime, maintenance frequency, and operating costs, improving overall production uptime.

5. How does an SMD reflow machine contribute to environmental sustainability?

By enabling the use of lead-free solder and reducing nitrogen gas consumption through advanced control systems, SMD reflow machines help manufacturers comply with environmental standards and reduce their ecological footprint.