Content Menu

● Introduction

● Understanding SMT Lines

>> What is SMT?

>> Components of an SMT Line

● The Role of an Operator in SMT Lines

>> Responsibilities of an Operator

>> Skills Required

● Can One Operator Effectively Manage an SMT Line?

>> Advantages of a Solitary Operator

>> Challenges Faced by a Solitary Operator

● Strategies for Success as a Solitary Operator

>> Automation

>> Workflow Optimization

>> Continuous Training

● Key Processes in an SMT Line

● Case Studies of Successful Solitary Operators

>> Example 1: Small Electronics Manufacturer

>> Example 2: Prototype Development Firm

● Measuring Efficiency in SMT Lines

>> Line Efficiency

>> Output Per Hour

● Conclusion

● FAQ

>> 1. What are the main responsibilities of an SMT line operator?

>> 2. What skills are essential for an effective SMT line operator?

>> 3. How can automation benefit a solitary operator on an SMT line?

>> 4. What challenges does a solitary operator face when managing an SMT line?

>> 5. How can continuous training improve efficiency for a solitary operator?

● Citations:

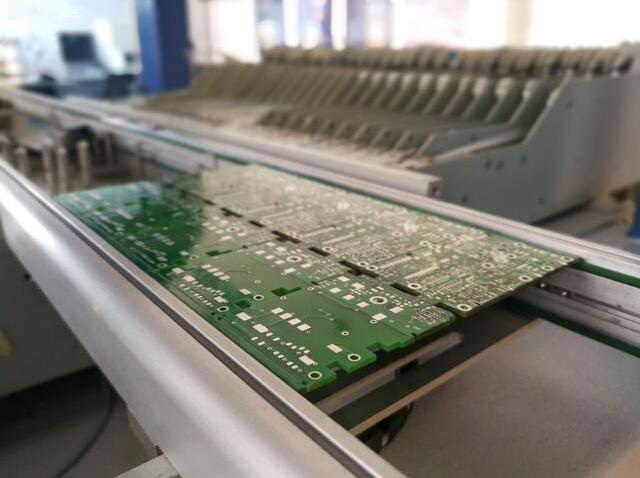

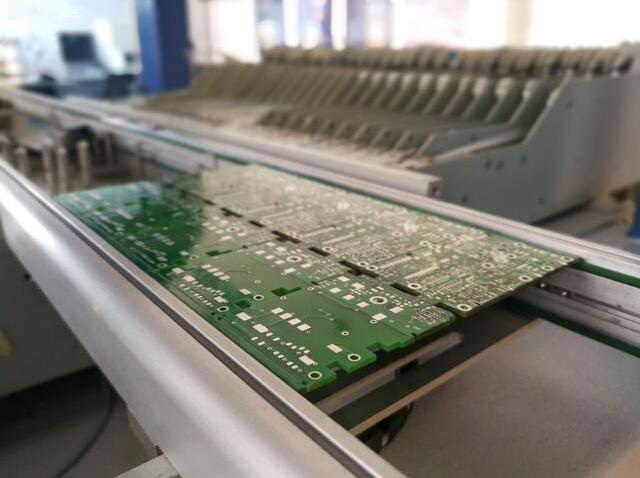

Introduction

Surface Mount Technology (SMT) lines are critical in the manufacturing of electronic components, enabling the production of compact and efficient devices. Traditionally, these lines require a team of operators to manage the various processes involved, from placing components on printed circuit boards (PCBs) to soldering and inspection. However, the question arises: can a solitary operator effectively run an SMT line? This article explores the feasibility, challenges, and strategies for a single operator to manage an SMT line efficiently.

Understanding SMT Lines

What is SMT?

Surface Mount Technology is a method used to mount electronic components directly onto the surface of PCBs. This technology has revolutionized electronics manufacturing due to its advantages over traditional through-hole technology, including:

- Higher component density: SMT allows for more components to be placed on a PCB.

- Reduced size and weight: Smaller components lead to lighter and more compact devices.

- Improved performance: Shorter electrical paths can enhance performance.

Components of an SMT Line

An SMT line typically consists of several key components:

- Pick and Place Machines: These machines are responsible for accurately placing components onto PCBs.

- Solder Paste Printers: They apply solder paste to the PCB before components are placed.

- Reflow Ovens: These ovens heat the assembled boards to melt solder paste, securing the components.

- Inspection Systems: Automated Optical Inspection (AOI) systems check for defects post-assembly.

Each of these components plays a crucial role in ensuring that the final product meets quality standards.

The Role of an Operator in SMT Lines

Responsibilities of an Operator

An operator on an SMT line is tasked with several responsibilities:

- Monitoring Equipment: Ensuring that all machines are functioning correctly and addressing any issues that arise.

- Quality Control: Performing inspections to ensure that assembled boards meet specifications.

- Material Management: Managing inventory levels of components and solder paste.

- Data Logging: Keeping records of production metrics for analysis and reporting.

Skills Required

To effectively manage these responsibilities, an operator must possess various skills:

- Technical Knowledge: Understanding how each machine operates and how to troubleshoot issues.

- Attention to Detail: Being able to spot defects or errors in the assembly process.

- Problem-Solving Skills: Quickly addressing any problems that may arise during production.

Can One Operator Effectively Manage an SMT Line?

Advantages of a Solitary Operator

Running an SMT line with a solitary operator can offer several advantages:

- Cost Efficiency: Reducing labor costs by employing fewer operators can significantly lower operational expenses.

- Streamlined Communication: With only one person managing the line, communication barriers are eliminated, leading to quicker decision-making.

- Flexibility: A solitary operator can adapt quickly to changes in production requirements without needing to coordinate with others.

Challenges Faced by a Solitary Operator

However, there are also significant challenges associated with this approach:

- Increased Workload: A single operator must manage multiple tasks simultaneously, which can lead to fatigue and errors.

- Limited Oversight: Without additional operators, it may be difficult to maintain quality control throughout the production process.

- Skill Limitations: While one person may excel in certain areas, they may lack expertise in others, leading to potential inefficiencies.

Strategies for Success as a Solitary Operator

To successfully run an SMT line as a solitary operator, several strategies can be employed:

Automation

Investing in automated systems can significantly reduce the workload on a single operator. For example:

- Automated Inspection Systems: Implementing AOI systems can help ensure quality without requiring constant human oversight.

- Smart Manufacturing Technologies: Utilizing IoT devices can provide real-time data about machine performance and production metrics, allowing for proactive management.

Workflow Optimization

Streamlining workflows is essential for efficiency. Considerations include:

- Layout Design: Organizing the workspace so that tools and materials are easily accessible can reduce time spent searching for items.

- Task Prioritization: Identifying critical tasks that require immediate attention can help manage workload effectively.

Continuous Training

A solitary operator should engage in continuous training to enhance their skills and knowledge. This includes:

- Technical Training: Regularly updating skills related to new machines or technologies used in SMT processes.

- Quality Control Training: Learning advanced inspection techniques can improve overall product quality.

Key Processes in an SMT Line

Understanding the core processes involved in an SMT line is crucial for effective management. The typical sequence includes:

1. Solder Paste Printing: The PCBs first pass through a solder paste printer that deposits a controlled pattern of solder paste onto the contact pads where components will be placed. This step is critical as it ensures proper adhesion during soldering.

2. SMD Component Placement: Next, pick-and-place machines precisely populate the PCBs by rapidly picking components from feeders and placing them on their designated solder-paste-coated pads in the programmed sequence. The speed and accuracy of this process are vital for maintaining high throughput rates.

3. Solder Reflow: The populated boards then pass through an industrial soldering oven that melts or reflows the solder paste to form permanent electrical solder joints that affix the SMDs to the PCB. This step requires careful temperature control to avoid damaging sensitive components.

4. Conformal Coating: An optional coating machine may then deposit a protective plastic coating layer onto the assembled PCBs providing insulation and preventing damage from environmental factors like moisture or dust.

5. Inspection: After assembly, boards undergo inspection using AOI systems or manual checks to identify defects such as misaligned components or insufficient solder joints. This step is crucial for ensuring product reliability before shipping out finished goods.

Case Studies of Successful Solitary Operators

Example 1: Small Electronics Manufacturer

A small electronics manufacturer successfully implemented a solitary operator model by investing in automated equipment. The operator was able to manage the pick-and-place machine, solder paste printer, and reflow oven efficiently due to streamlined workflow and automated inspection systems. As a result, production increased by 30% while maintaining high-quality standards.

Example 2: Prototype Development Firm

In another case, a prototype development firm utilized a solitary operator for short-run productions. The operator was trained across multiple functions, allowing them to switch roles as needed. This flexibility enabled rapid turnaround times for prototypes while keeping costs low. The firm reported higher customer satisfaction due to quicker delivery times without sacrificing quality.

Measuring Efficiency in SMT Lines

Efficiency measurement is critical when evaluating the performance of an SMT line operated by a solitary individual. Key metrics include:

Line Efficiency

Line efficiency is defined as the ratio of productive time (when machines are actively placing parts) versus total staffed hours. For instance:

Line Efficiency=(Placement Time/ Staffed TimePlacement Time)×100

Research shows that world-class efficiency for single lines typically reaches above 75%, while high-volume lines can exceed 80% efficiency[1][2]. This metric helps identify areas needing improvement and informs operational adjustments necessary for maximizing productivity under solitary operation conditions.

Output Per Hour

Another important metric is output per hour per machine operator/inspector. According to industry benchmarks, average output per placement hour stands at approximately 4,450 components across various settings[1]. Tracking this metric allows operators to gauge their effectiveness continually and make necessary adjustments based on real-time data analysis[3].

Conclusion

While running an SMT line with a solitary operator presents both advantages and challenges, it is feasible with the right strategies in place. Automation, workflow optimization, and continuous training are key factors that can help ensure efficiency and maintain quality standards. As technology continues to evolve, the potential for solitary operators in SMT lines will likely increase, offering manufacturers new ways to optimize their operations while reducing costs.

Ultimately, embracing advanced technologies such as IoT-driven solutions and automated inspection systems will empower solitary operators not only to manage their workloads effectively but also enhance overall production quality—paving the way for future innovations within electronic manufacturing processes.

FAQ

1. What are the main responsibilities of an SMT line operator?

An SMT line operator is responsible for monitoring equipment performance, conducting quality control inspections, managing material inventory, and logging production data.

2. What skills are essential for an effective SMT line operator?

Essential skills include technical knowledge of machinery operation, attention to detail for quality control, and problem-solving abilities for troubleshooting issues that arise during production.

3. How can automation benefit a solitary operator on an SMT line?

Automation can reduce workload by allowing machines to handle repetitive tasks such as inspection or component placement, enabling the operator to focus on oversight and quality assurance.

4. What challenges does a solitary operator face when managing an SMT line?

Challenges include increased workload leading to potential fatigue, limited oversight affecting quality control, and skill limitations across various tasks required on the line.

5. How can continuous training improve efficiency for a solitary operator?

Continuous training enhances technical skills and knowledge about new technologies or inspection methods, improving overall efficiency and product quality on the SMT line.

Citations:

[1] https://iconnect007.com/index.php/article/52474/--line-efficiency-and-productivity-measures/52477?skin=smt

[2] https://www.mainpcba.com/smt-line-a-complete-guide-on-surface-mount-technology-line/

[3] https://fw.1stsmt.com/blog/the-advantages-and-challenges-of-smt-in-automated-manufacturing

[4] https://ece.iisc.ac.in/~rajeshs/reprints/201811IOTAIS_KarEtAl.pdf

[5] https://global.yamaha-motor.com/business/smt/concept/recipe/

[6] https://www.linkedin.com/advice/1/what-benefits-challenges-using-surface-mount-technology

[7] https://www.smtfactory.com/Optimizing-Efficiency-Strategies-for-A-Smooth-SMT-Line-Production-Process-id47463586.html

[8] https://www.youtube.com/watch?v=HRvADApuyzA

[9] https://www.criticalmanufacturing.com/blog/material-optimization-in-the-smt-and-electronics-assembly-industries/

[10] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/