Content Menu

● Introduction to SMD LED Pick and Place Machines

>> Key Features of SMD LED Pick and Place Machines

● Handling Multiple Sizes of LEDs

● Benefits of Using SMD LED Pick and Place Machines

● Challenges and Considerations

● Technological Advancements and Trends

● Applications in Various Industries

● Market Outlook and Growth

● Common Issues and Troubleshooting

● Future Developments and Innovations

● Conclusion

● FAQs

>> 1. What is the typical component range for an SMD LED pick and place machine?

>> 2. How does the vision system enhance the efficiency of SMD LED pick and place machines?

>> 3. What are the benefits of using SMD LED pick and place machines in LED manufacturing?

>> 4. What factors determine a machine's ability to handle multiple LED sizes?

>> 5. How do SMD LED pick and place machines contribute to cost savings in manufacturing?

● Citations:

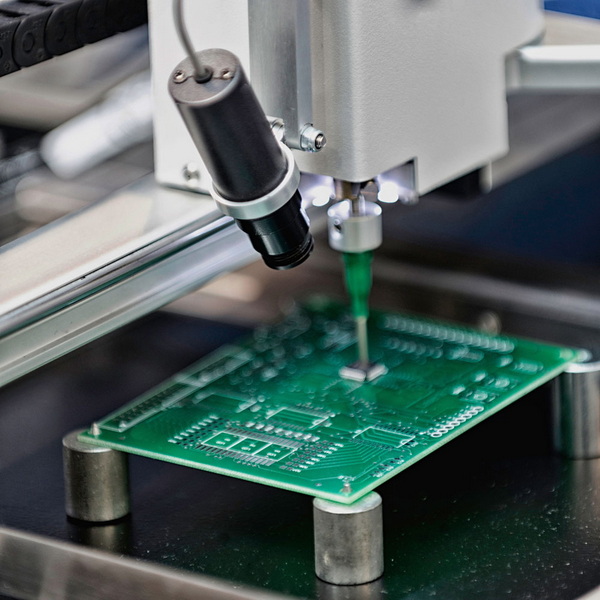

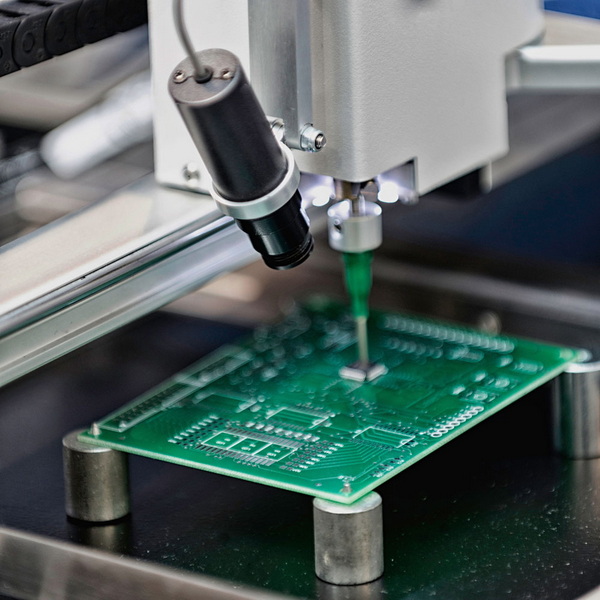

The SMD LED pick and place machine is a crucial piece of equipment in the modern electronics manufacturing industry, particularly in the production of LED displays, automotive lights, and other LED-based products. These machines are designed to efficiently and accurately place surface-mounted components, including LEDs, onto printed circuit boards (PCBs). The question of whether these machines can handle multiple sizes of LEDs is essential for manufacturers seeking to optimize their production lines for diverse product ranges.

Introduction to SMD LED Pick and Place Machines

SMD LED pick and place machines are advanced devices that integrate robotics, computer control systems, and vision technology to automate the assembly process. They are capable of handling a wide range of surface-mounted components, from small resistors and capacitors to larger ICs and LEDs. The versatility of these machines is a key factor in their widespread adoption across various industries.

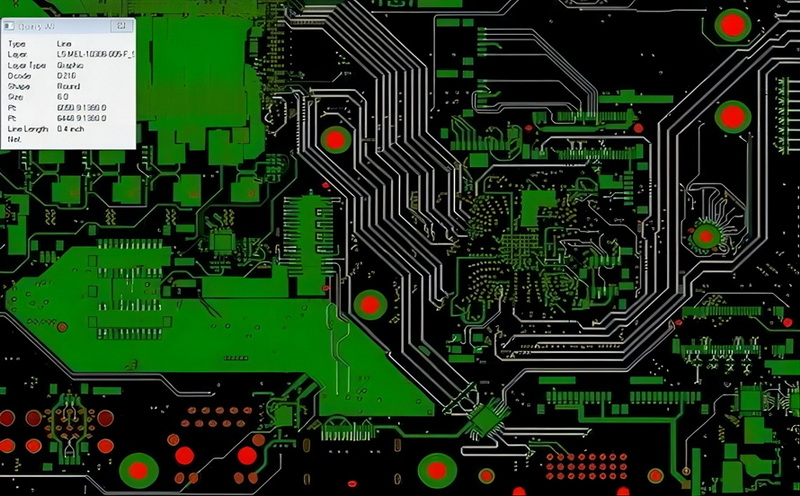

Key Features of SMD LED Pick and Place Machines

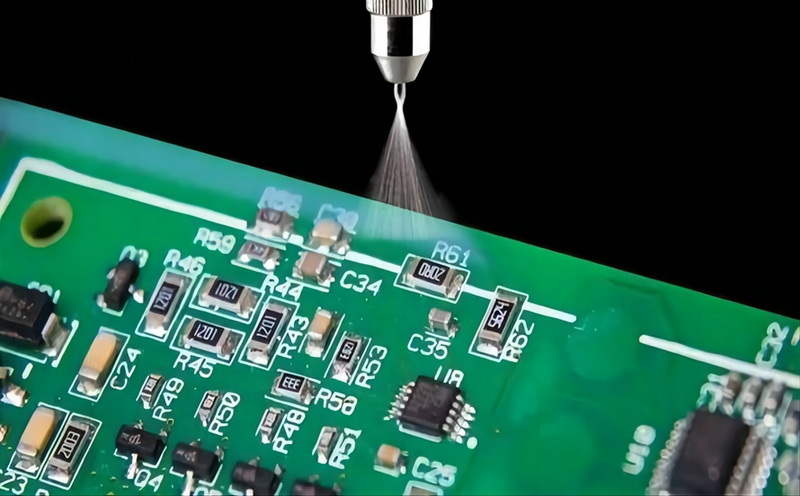

1. High Precision: These machines are equipped with precise positioning systems, ensuring accurate placement of components on PCBs. The position accuracy can be as precise as ±0.01mm, which is critical for handling small components like LEDs.

2. High Speed: SMD LED pick and place machines can achieve high placement speeds, often exceeding 40,000 components per hour (CPH), significantly increasing production efficiency.

3. Versatility: They can handle various types and sizes of components, including LEDs, making them ideal for diverse product lines.

4. Automation Capabilities: These machines are designed for continuous operation with minimal human intervention, reducing errors and downtime.

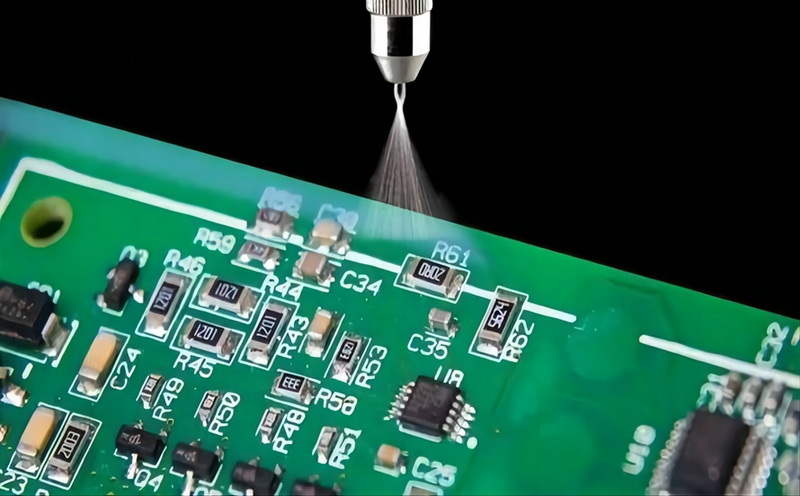

5. Vision Systems: Equipped with advanced vision systems, such as flying cameras and IC cameras, these machines can recognize and align components during placement, enhancing efficiency and accuracy.

Handling Multiple Sizes of LEDs

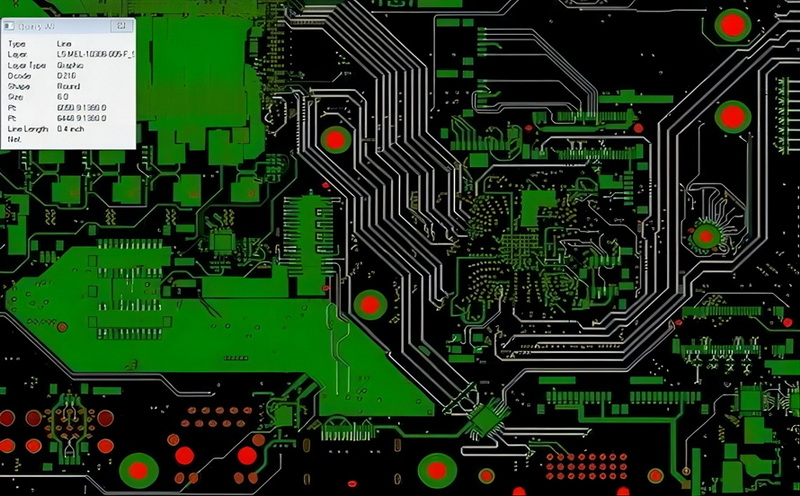

The ability of an SMD LED pick and place machine to handle multiple sizes of LEDs is primarily determined by its design specifications and component range. Most modern machines are capable of handling a wide range of component sizes, from small 0201 packages to larger ICs and LEDs up to 40mm x 40mm. The key factors that enable this versatility include:

- Component Range: The machine's ability to handle components of varying sizes is crucial. Machines like the NeoDen N10P can handle components from 0201 to larger ICs, accommodating different LED sizes.

- Nozzle Flexibility: Machines with automatic nozzle change functions and multiple nozzle positions enhance the flexibility in handling different component sizes.

- Vision System: Advanced vision systems allow for precise recognition and alignment of components, regardless of their size.

Benefits of Using SMD LED Pick and Place Machines

The use of SMD LED pick and place machines offers several benefits in LED manufacturing:

1. Enhanced Efficiency: By automating the placement process, these machines significantly reduce production time and labor costs.

2. Improved Accuracy: The precision of these machines minimizes errors, leading to higher product quality and reliability.

3. Cost Savings: Reduced rework and scrap, combined with increased production capacity, result in cost savings and revenue growth.

4. Flexibility: The ability to handle multiple component sizes allows manufacturers to produce a variety of products on the same line, enhancing flexibility and reducing setup times.

Challenges and Considerations

While SMD LED pick and place machines offer numerous advantages, there are challenges and considerations to keep in mind:

1. Initial Investment: The cost of purchasing and maintaining these machines can be high, requiring significant upfront investment.

2. Component Compatibility: Ensuring that the machine can handle the specific sizes and types of LEDs required for production is crucial.

3. Training and Support: Operators need training to fully utilize the machine's capabilities, and ongoing technical support is essential for maintaining efficiency.

Technological Advancements and Trends

The SMD LED pick and place machine market is experiencing significant technological advancements, driven by trends such as automation, artificial intelligence, and Industry 4.0. These advancements include:

- Integration of AI and Robotics: The adoption of AI and robotics enhances machine efficiency and precision, allowing for real-time adjustments and improved component handling.

- Energy Efficiency: There is a growing emphasis on developing energy-efficient machines that reduce power consumption without compromising performance.

- Modular Design: Modular designs allow for easier maintenance and upgrades, extending the lifespan of the machines and reducing downtime.

- 3D Printing Integration: The integration of 3D printing technology in machine manufacturing enables the creation of customized parts and components, enhancing machine flexibility and reducing production costs.

Applications in Various Industries

SMD LED pick and place machines are used across multiple industries, including:

1. LED Lighting: These machines are crucial in the LED lighting industry for producing high-quality, efficient lighting products. They enable precise placement of LEDs on PCBs, ensuring consistent brightness and reliability.

2. Automotive: In the automotive sector, these machines are used for manufacturing LED-based components such as dashboard displays and headlights.

3. Consumer Electronics: They are essential for producing consumer electronics like smartphones and televisions, where precise component placement is critical.

4. Advertising and Display: In the advertising and display industry, SMD LED pick and place machines help manufacture large LED screens used for outdoor advertising and event displays.

Market Outlook and Growth

The market for SMD LED pick and place machines is expected to grow significantly, driven by the increasing demand for advanced electronics and the trend towards miniaturization. The global SMT placement equipment market is projected to expand due to factors such as the rise of Industry 4.0 and the IoT, which emphasize automation and precision in manufacturing.

Common Issues and Troubleshooting

While SMD LED pick and place machines are highly efficient, they can experience issues such as component pick-up and release problems, inaccurate fiducial recognition, and component damage. These issues can be addressed through regular maintenance, proper calibration, and ensuring optimal vacuum and nozzle pressures[6]. Additionally, using the correct nozzle setup for specific components, such as high-power LEDs with silicone domes, is crucial to prevent sticking issues[3].

Future Developments and Innovations

Future developments in SMD LED pick and place machines are likely to focus on further integrating AI and machine learning to enhance predictive maintenance and real-time quality control. This will enable machines to detect potential issues before they occur, reducing downtime and improving overall efficiency.

Conclusion

In conclusion, SMD LED pick and place machines are highly capable of handling multiple sizes of LEDs, thanks to their advanced design and versatility. These machines play a vital role in enhancing production efficiency, accuracy, and flexibility in the LED manufacturing industry. By understanding the capabilities and benefits of these machines, manufacturers can optimize their production lines to meet the demands of a rapidly evolving market.

FAQs

1. What is the typical component range for an SMD LED pick and place machine?

An SMD LED pick and place machine typically handles components from small 0201 packages up to larger ICs and LEDs, often up to 40mm x 40mm in size.

2. How does the vision system enhance the efficiency of SMD LED pick and place machines?

The vision system in these machines enhances efficiency by recognizing and aligning components during placement, allowing for precise and rapid component mounting.

3. What are the benefits of using SMD LED pick and place machines in LED manufacturing?

The benefits include enhanced efficiency, improved accuracy, cost savings, and flexibility in handling diverse component sizes.

4. What factors determine a machine's ability to handle multiple LED sizes?

Key factors include the machine's component range, nozzle flexibility, and advanced vision systems.

5. How do SMD LED pick and place machines contribute to cost savings in manufacturing?

These machines contribute to cost savings by reducing labor costs, minimizing rework and scrap, and increasing production capacity.

Citations:

[1] https://www.hct-smt.com/blog/led-display-smt-pick-and-place-machine

[2] https://www.hct-smt.com/blog/exploring-automatic-led-pick-and-place-machines%E2%80%8B

[3] https://www.circuitinsight.com/pdf/led_pick_place_challenge_ipc.pdf

[4] https://en.wikipedia.org/wiki/Pick-and-place_machine

[5] https://www.neodensmt.com/other-products/smd-led-mounting-machine-neoden5.html

[6] https://www.zjyingxing.com/info/what-are-the-common-smt-pick-and-place-machine-88387624.html

[7] https://www.charmhigh-tech.com/quality-7840270-desktop-chmt36-smt-smd-led-pick-and-place-machine-29-feeders-chip-mounter

[8] https://www.itechsmt.com/blogs/news/10-hot-topics-about-smt-pick-and-place-machine

[9] https://www.zjyingxing.com/info/what-are-the-reasons-for-poor-smt-pick-and-pla-88683734.html

[10] https://it.hct-smt.com/blog/what-is-a-pick-and-place-smd-led-machine

[11] https://www.cnlcdisplay.com/smd-packaging-the-key-driving-force-behind-led-displays

[12] https://www.circuitinsight.com/programs/53505.html

[13] https://downloads.cree-led.com/files/da/x/XLamp-Pick-Place.pdf

[14] https://www.tronstol.com/the-three-major-development-trends-of-the-pick-and-place-machine-in-the-future.html

[15] https://www.eevblog.com/forum/manufacture/the-reality-of-a-pick-and-place-lifestyle/

[16] https://essemtec.com/en/applications/

[17] https://www.smtmachine.eu/role-of-smt-production-line-in-the-led-industry/

[18] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[19] https://www.instructables.com/Manual-Pick-and-Place-Machine-for-SMD-Components/

[20] https://www.hct-smt.com/blog/led-placement-machine--revolutionizing-electronics-manufacturing