Content Menu

● Introduction

● Understanding Pick and Place Machines

>> Overview

>> Key Components

● Breakaway Rails and Panelization

>> Purpose

>> Benefits

● Operating Without Breakaway Rails

>> Feasibility

>> Challenges

>> Solutions

● Case Study: NeoDen4 SMT Pick and Place Machine

● Designing Custom Solutions

>> DIY and Open-Source Solutions

● Advanced Technologies in Pick and Place Machines

>> High-Speed Placement

>> Smart Feeding Systems

>> Integration with Other Manufacturing Processes

● Environmental Considerations

>> Energy Efficiency

>> Waste Reduction

● Future Developments

● Conclusion

● FAQ

>> 1. What is the primary function of a pick and place machine?

>> 2. Can a pick and place machine work without a breakaway rail?

>> 3. What are the benefits of using breakaway rails in PCB assembly?

>> 4. How do custom fixtures help in operating without breakaway rails?

>> 5. What are some alternatives for small-scale manufacturers or hobbyists?

Introduction

In the realm of electronics manufacturing, pick and place machines play a crucial role in the assembly of Surface Mount Technology (SMT) components onto printed circuit boards (PCBs). These machines are designed to efficiently place small electrical components such as capacitors, resistors, and integrated circuits onto PCBs with high precision and speed. One common practice in PCB assembly involves using breakaway rails or panelization to facilitate easier handling and processing by the pick and place machine. However, the question arises: Can a pick and place machine operate effectively without a breakaway rail?

Understanding Pick and Place Machines

Overview

A pick and place machine is an automated device used in the electronics assembly industry for placing SMT components onto PCBs. It typically consists of a robotic head equipped with vacuum nozzles that pick components from reels or trays and accurately place them onto the PCB. The machine's ability to handle a wide range of components and board sizes makes it versatile for various manufacturing needs.

Key Components

- Robotic Head: Equipped with individually controlled vacuum nozzles, the head moves along an X-Y gantry to pick and place components.

- Component Feeders: These can be in the form of tape reels or trays, holding a variety of SMT components.

- Vision System: Some advanced machines include cameras for inspecting components during the placement process, ensuring accuracy and quality.

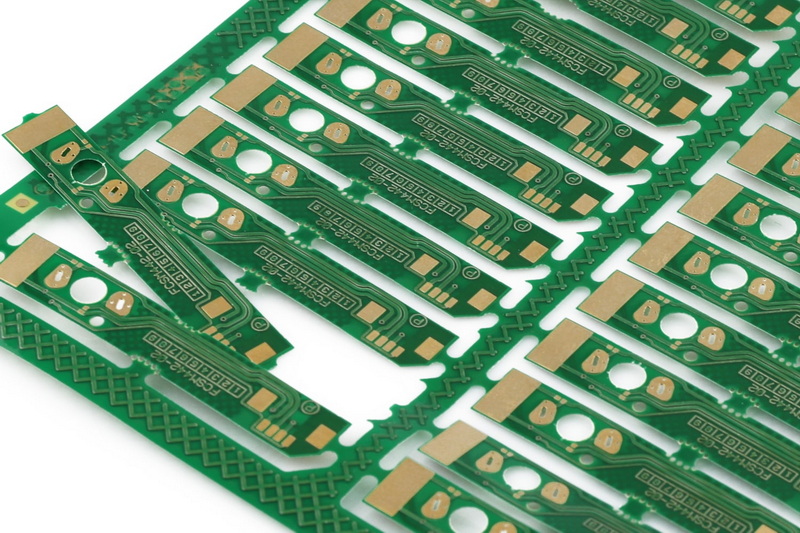

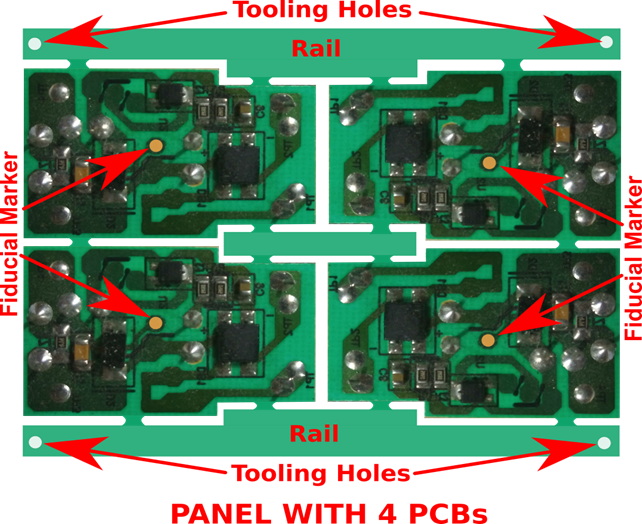

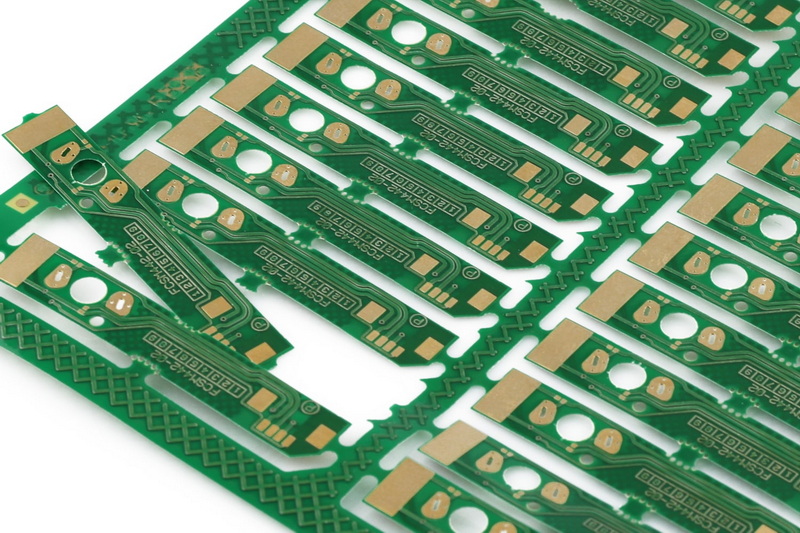

Breakaway Rails and Panelization

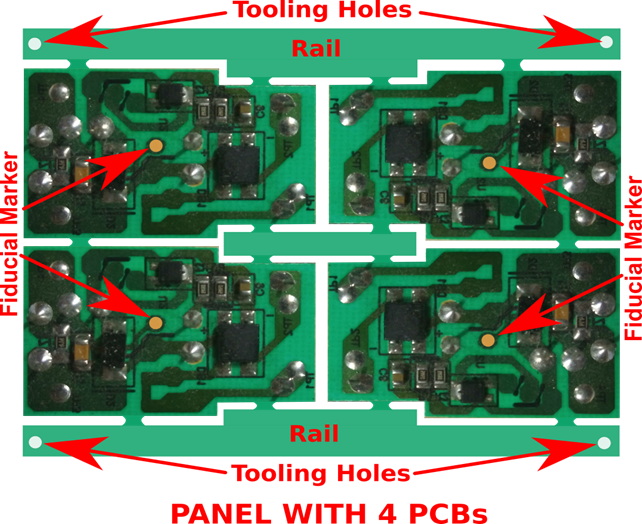

Purpose

Breakaway rails are used in panelization to connect multiple PCBs together, making it easier to handle them during the manufacturing process. This setup allows for more efficient assembly, as multiple boards can be processed simultaneously. Once the assembly is complete, the individual PCBs are separated from the panel by breaking along the rails.

Benefits

- Efficiency: Panelization with breakaway rails increases throughput by allowing multiple boards to be processed at once.

- Cost-Effectiveness: While the initial cost of panelized boards may be higher, it can reduce overall production costs by minimizing handling errors and improving assembly speed.

- Reduced Handling Errors: By processing multiple boards as a single unit, the risk of individual board misalignment or damage is reduced.

Operating Without Breakaway Rails

Feasibility

Yes, a pick and place machine can operate without a breakaway rail. However, this approach requires careful planning and communication with the assembler to ensure smooth processing. Boards without breakaway rails must be individually placed on the machine's worktable, which can be more time-consuming and may increase the risk of errors if not properly aligned.

Challenges

- Alignment: Ensuring accurate alignment of individual boards on the machine's worktable is crucial to prevent placement errors.

- Handling: Without panelization, each board must be handled separately, which can slow down the assembly process.

- Increased Labor Costs: The need for manual handling of each board can increase labor costs compared to panelized production.

Solutions

To overcome these challenges, manufacturers can use magnetic fixtures or custom-designed holders to secure individual PCBs on the machine. This approach ensures stability and accurate placement of components.

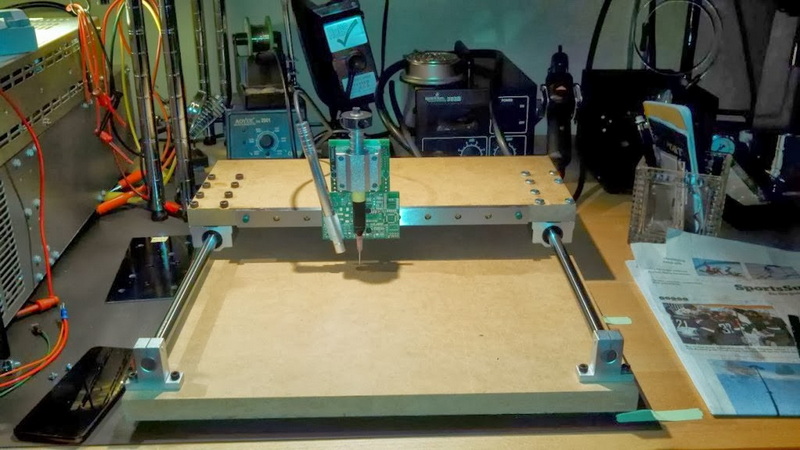

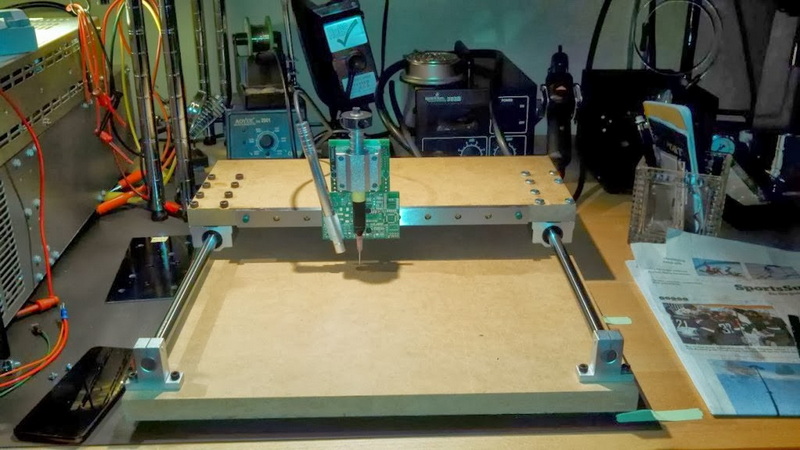

Case Study: NeoDen4 SMT Pick and Place Machine

The NeoDen4 is a desktop pick and place machine designed for high precision and capacity, suitable for small to medium-sized enterprises. It features a vision system and four independently controllable nozzles, making it ideal for precise component placement without the need for breakaway rails. The machine supports magnetic fixtures for PCB support, allowing for efficient handling of individual boards.

Designing Custom Solutions

For those looking to operate without breakaway rails, designing custom fixtures or using existing machines with adaptable worktables can be beneficial. This approach allows for flexibility in handling different board sizes and configurations.

DIY and Open-Source Solutions

Projects like the OpenPnP software and DIY pick and place machines offer affordable alternatives for small-scale manufacturers or hobbyists. These solutions allow users to build or customize their machines to accommodate specific needs, such as handling boards without breakaway rails.

Advanced Technologies in Pick and Place Machines

High-Speed Placement

Modern pick and place machines are equipped with advanced technologies that enable high-speed component placement. This is particularly beneficial for large-scale production, where efficiency is crucial. Even without breakaway rails, these machines can maintain high productivity by quickly processing individual boards.

Smart Feeding Systems

Some advanced machines incorporate smart feeding systems that automatically detect and adjust to different component types, further enhancing efficiency and reducing setup times. This feature is especially useful when handling a variety of components on boards without breakaway rails.

Integration with Other Manufacturing Processes

Pick and place machines are increasingly integrated with other manufacturing processes, such as inspection and soldering systems, to create a seamless production line. This integration can help streamline the assembly process even when working with individual boards.

Environmental Considerations

Energy Efficiency

Modern pick and place machines are designed to be energy-efficient, reducing operational costs and environmental impact. This is an important consideration for manufacturers looking to minimize their ecological footprint while maintaining productivity.

Waste Reduction

By optimizing component placement and reducing handling errors, pick and place machines can help minimize waste generation during PCB assembly. This aligns with sustainable manufacturing practices and can be beneficial even when operating without breakaway rails.

Future Developments

The future of pick and place technology includes advancements in automation, AI integration, and enhanced precision. These developments will further improve the efficiency and flexibility of PCB assembly, making it easier to operate without breakaway rails while maintaining high productivity standards.

Conclusion

In conclusion, while pick and place machines can operate without breakaway rails, it is essential to consider the potential challenges and benefits. With proper planning and the use of custom fixtures or adaptable machines, manufacturers can efficiently assemble PCBs without panelization. However, for high-volume production, traditional panelization methods may still offer advantages in terms of efficiency and cost-effectiveness.

FAQ

1. What is the primary function of a pick and place machine?

A pick and place machine is used to assemble SMT components onto PCBs by picking components from reels or trays and accurately placing them onto the board.

2. Can a pick and place machine work without a breakaway rail?

Yes, a pick and place machine can operate without a breakaway rail, but it requires careful handling and alignment of individual boards.

3. What are the benefits of using breakaway rails in PCB assembly?

Breakaway rails facilitate efficient handling and processing of multiple PCBs simultaneously, reducing errors and increasing throughput.

4. How do custom fixtures help in operating without breakaway rails?

Custom fixtures, such as magnetic holders, can secure individual PCBs on the machine, ensuring stability and accurate component placement.

5. What are some alternatives for small-scale manufacturers or hobbyists?

Alternatives include DIY pick and place machines and open-source software like OpenPnP, which offer flexibility and affordability for small-scale operations.