Content Menu

● Introduction to Laser SMT Stencil Cutters

>> Advantages of Laser Cutting Technology

● Using Laser SMT Stencil Cutters for DIY Projects

>> DIY SMT Stencil Creation

>> Benefits for DIY Projects

● Challenges and Considerations

● Tips for Successful DIY Projects

● Applications Beyond SMT Stencils

● Storage and Maintenance of Laser-Cut Stencils

● Advanced Techniques for Laser Cutting

● Troubleshooting Common Issues

● Future Developments in Laser Technology

● Conclusion

● Frequently Asked Questions

>> 1. What Materials Can Be Used for Laser-Cut SMT Stencils?

>> 2. How Do I Achieve High Precision with a Laser SMT Stencil Cutter?

>> 3. Can I Use a Laser Cutter for Other DIY Projects Besides SMT Stencils?

>> 4. What Safety Precautions Should I Take When Using a Laser Cutter?

>> 5. How Do I Store and Maintain Laser-Cut Stencils?

Laser technology has revolutionized various industries, including electronics manufacturing, by providing precise and efficient tools for creating stencils. A laser SMT stencil cutter is particularly useful for surface mount technology (SMT) applications, allowing for the precise application of solder paste onto PCBs. But can this technology be adapted for DIY projects? In this article, we will explore the capabilities and applications of laser SMT stencil cutters in DIY settings.

Introduction to Laser SMT Stencil Cutters

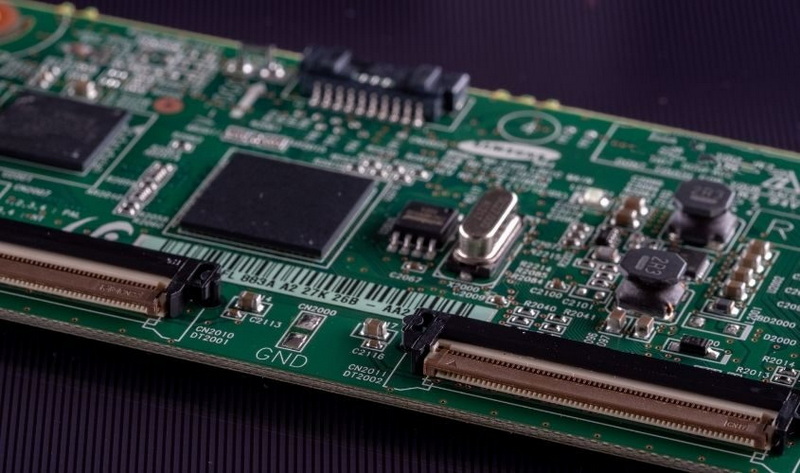

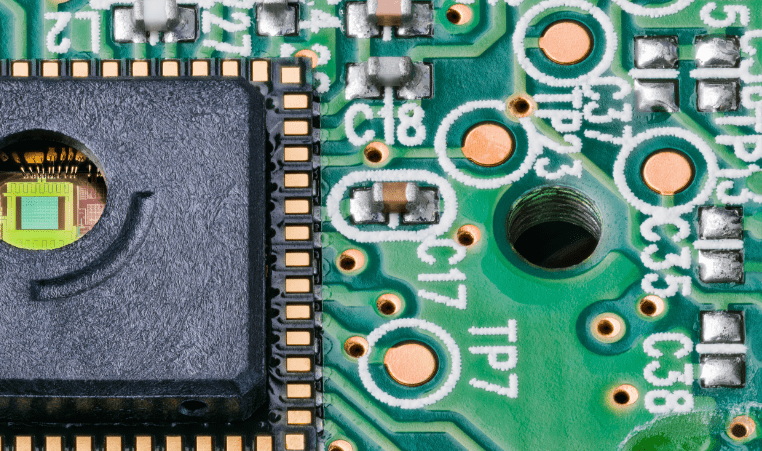

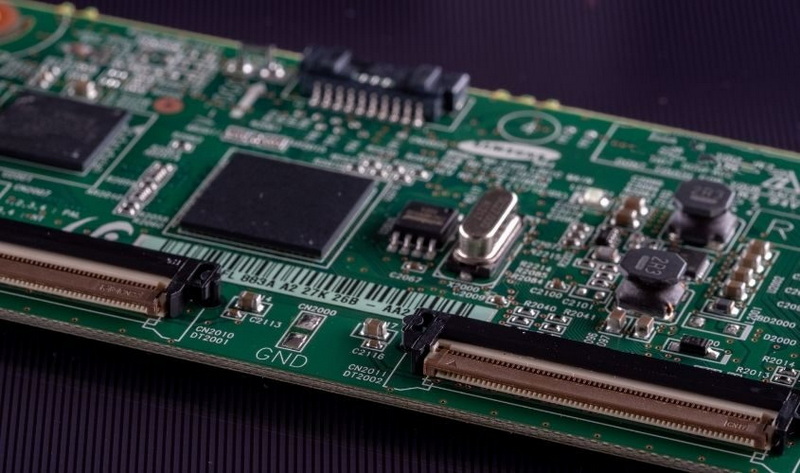

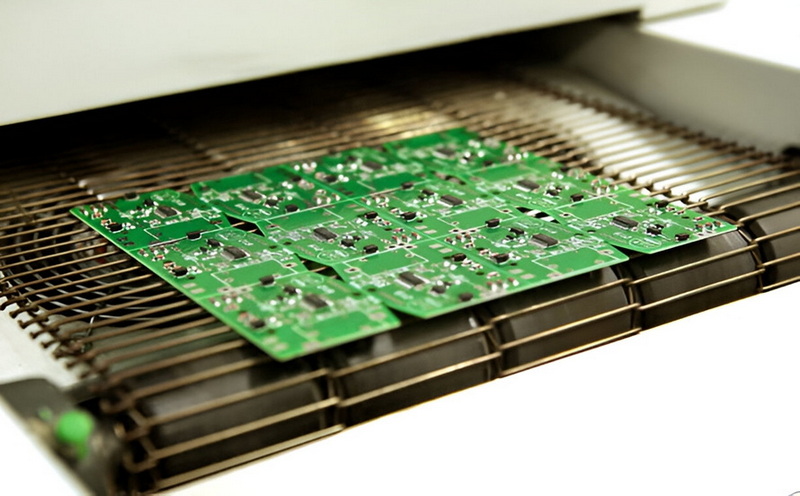

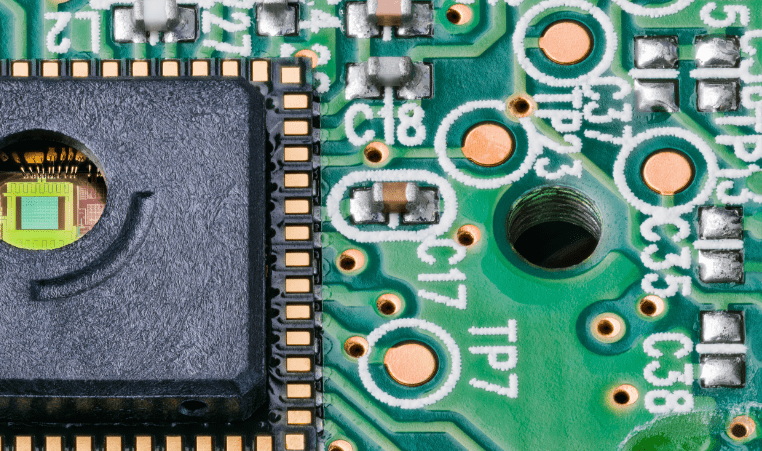

Laser SMT stencil cutters are designed to create stencils used in the assembly of surface mount components on printed circuit boards (PCBs). These stencils are crucial for applying solder paste accurately onto the PCB pads, ensuring that components are soldered correctly. The precision offered by laser cutting technology makes it ideal for creating stencils with complex designs and fine-pitch components.

Advantages of Laser Cutting Technology

- Precision: Laser cutting offers high precision, often with tolerances as tight as ±5 μm, ensuring accurate hole positions and shapes.

- Material Versatility: Laser cutters can work with a variety of materials, including mylar, stainless steel, and other metals, providing flexibility for different applications.

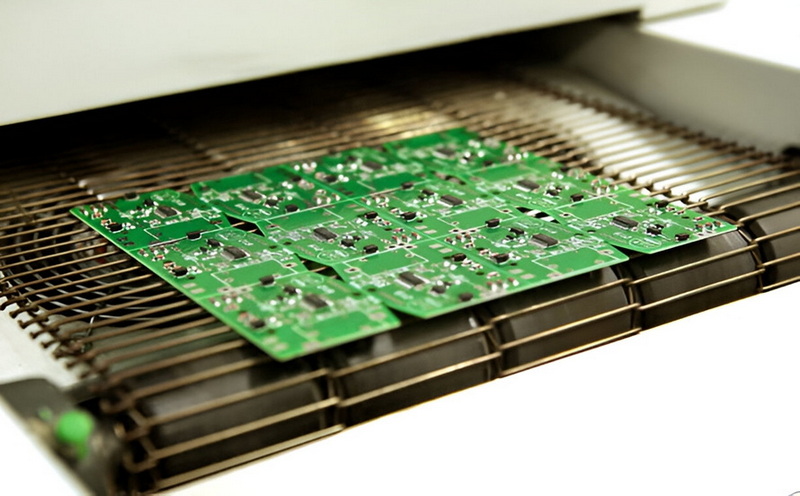

- Speed and Efficiency: Laser cutting is faster and more efficient than traditional methods, allowing for quick production of stencils.

Using Laser SMT Stencil Cutters for DIY Projects

For DIY enthusiasts and small-scale electronics manufacturers, laser SMT stencil cutters can be incredibly useful. Here are some ways they can be utilized:

DIY SMT Stencil Creation

1. Material Selection: Choose materials like mylar or thin stainless steel for the stencil. Mylar is particularly popular for DIY projects due to its ease of use and cost-effectiveness.

2. Design Preparation: Use software to create a design for the stencil, focusing on the solder paste layer of your PCB design. Ensure that the design includes alignment holes for accurate positioning.

3. Laser Cutting: Set up your laser cutter with appropriate settings for the material. For mylar, engraving rather than cutting through is often recommended to avoid melting and burning.

4. Post-processing: Clean and inspect the stencil for any debris or imperfections. Apply a protective coating if necessary to enhance durability.

Benefits for DIY Projects

- Cost Savings: Creating stencils in-house can save time and money compared to ordering from external suppliers.

- Customization: Laser cutters allow for custom stencil designs tailored to specific PCB layouts, which is particularly useful for prototyping or small-batch production.

- Precision: The high precision of laser-cut stencils ensures accurate solder paste application, reducing errors and improving the quality of DIY projects.

Challenges and Considerations

While laser SMT stencil cutters offer many benefits, there are challenges to consider:

- Equipment Cost: Although laser cutters are becoming more affordable, they still represent a significant investment for many DIY enthusiasts.

- Material Handling: Working with thin materials requires careful handling to avoid damage or deformation.

- Safety Precautions: Always use proper safety equipment when operating a laser cutter, including goggles and a well-ventilated workspace.

Tips for Successful DIY Projects

To maximize the effectiveness of a laser SMT stencil cutter in DIY projects:

- Experiment with Settings: Test different laser power and speed settings to achieve optimal results for your material.

- Use Alignment Holes: Include alignment holes in your stencil design to ensure accurate positioning on the PCB.

- Maintain Equipment: Regularly clean and maintain your laser cutter to ensure consistent performance.

Applications Beyond SMT Stencils

Laser cutters are versatile tools that can be used for a wide range of DIY projects beyond SMT stencils:

- Crafting: Create intricate designs for woodworking, metalworking, or textile projects.

- Home Decor: Use laser-cut stencils for custom painting or etching on walls, furniture, or signs.

- Art Projects: Laser cutters can be used to create detailed designs in various materials, from paper to wood.

Storage and Maintenance of Laser-Cut Stencils

Proper storage and maintenance are crucial to extend the lifespan of laser-cut stencils:

- Cleanliness: Regularly clean the stencils to remove any debris or residue.

- Storage Conditions: Store stencils in a dry, clean environment away from direct sunlight to prevent degradation.

- Handling: Handle stencils carefully to avoid bending or scratching.

Advanced Techniques for Laser Cutting

For more complex projects, consider using advanced techniques:

- Thermal Management: Use techniques like sandwiching materials to prevent overheating during cutting.

- Optimized Settings: Adjust laser settings based on material thickness and design complexity.

- Ventilation: Ensure good ventilation to prevent fumes from accumulating.

Troubleshooting Common Issues

When using a laser SMT stencil cutter, you may encounter some common issues:

- Inaccurate Cuts: Check if the laser is properly calibrated and if the material is correctly aligned.

- Material Damage: Adjust laser power or speed to prevent overheating or burning.

- Maintenance: Regularly clean the laser lens and mirrors to maintain optimal performance.

Future Developments in Laser Technology

As technology advances, we can expect improvements in laser cutting precision and efficiency. Future developments may include:

- Higher Precision: Advances in laser technology could lead to even tighter tolerances and more precise cuts.

- Increased Speed: Faster cutting speeds could further reduce production time for stencils.

- Material Expansion: New materials may become compatible with laser cutting, expanding the range of applications.

Conclusion

Laser SMT stencil cutters are indeed suitable for DIY projects, offering precision, customization, and cost savings. By understanding the capabilities and limitations of these tools, DIY enthusiasts can enhance the quality and efficiency of their electronics projects.

Frequently Asked Questions

1. What Materials Can Be Used for Laser-Cut SMT Stencils?

Laser-cut SMT stencils can be made from various materials, including mylar, stainless steel, and other metals. Mylar is popular for DIY projects due to its ease of use and cost-effectiveness.

2. How Do I Achieve High Precision with a Laser SMT Stencil Cutter?

To achieve high precision, ensure that your laser cutter is properly calibrated, and use appropriate settings for the material. Test cuts on scrap material can help fine-tune these settings.

3. Can I Use a Laser Cutter for Other DIY Projects Besides SMT Stencils?

Yes, laser cutters are versatile tools that can be used for a wide range of DIY projects, including crafting, woodworking, and metalworking. They are ideal for cutting intricate designs in various materials.

4. What Safety Precautions Should I Take When Using a Laser Cutter?

Always wear protective goggles and ensure good ventilation when operating a laser cutter. Avoid direct exposure to the laser beam and keep the workspace clean to prevent fires.

5. How Do I Store and Maintain Laser-Cut Stencils?

Store laser-cut stencils in a dry, clean environment to prevent damage. Regularly inspect and clean the stencils before use to maintain their precision and longevity.