Content Menu

● Introduction to Desktop SMD Pick and Place Machines

>> Key Features of Desktop SMD Pick and Place Machines

● Benefits for Small-Scale Production

>> Efficiency and Speed

>> Accuracy and Quality

>> Flexibility and Versatility

● Practical Applications in Small-Scale Production

>> Prototyping

>> Small Batch Production

>> Educational and Research Settings

● Choosing the Right Desktop SMD Pick and Place Machine

● Advanced Features and Technologies

>> Vision Systems

>> Auto Nozzle Changers

● Comparison with Large-Scale Machines

● Future Developments and Trends

● Conclusion

● Frequently Asked Questions

>> 1. What is the typical placement speed of a desktop SMD pick and place machine?

>> 2. Can desktop SMD pick and place machines handle large components?

>> 3. How do I program a desktop SMD pick and place machine?

>> 4. Are desktop SMD pick and place machines suitable for high-volume production?

>> 5. What are the key factors to consider when choosing a desktop SMD pick and place machine?

● Citations:

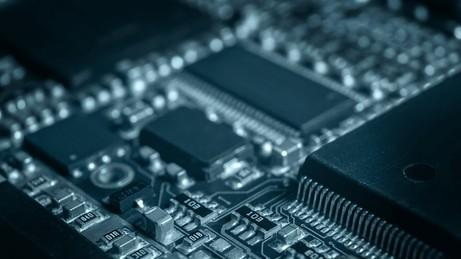

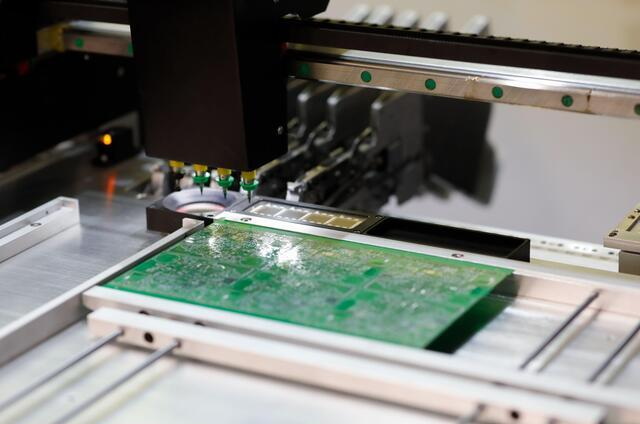

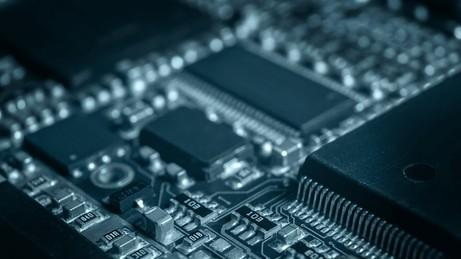

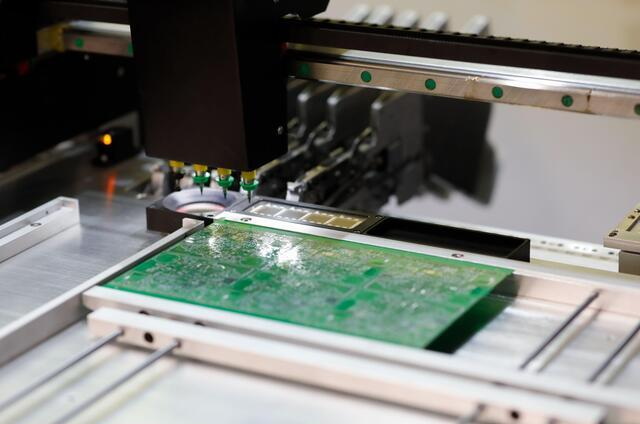

In the realm of electronics manufacturing, desktop SMD pick and place machines have emerged as a crucial tool for efficiently assembling printed circuit boards (PCBs). These machines are designed to automate the process of placing surface mount devices (SMDs) onto PCBs, significantly enhancing production speed and accuracy compared to manual assembly methods. The question arises: Can a desktop SMD pick and place machine be effectively utilized for small-scale production? This article delves into the capabilities, benefits, and practical applications of these machines in small-scale production environments.

Introduction to Desktop SMD Pick and Place Machines

Desktop SMD pick and place machines are compact, automated devices that fit on a standard workbench, making them ideal for small-scale production, prototyping, and educational settings. They typically feature advanced technologies such as vision systems, automatic feeders, and precision placement heads, which enable them to handle a wide range of SMD components with high accuracy.

Key Features of Desktop SMD Pick and Place Machines

1. Compact Design: These machines are designed to fit in small spaces, making them perfect for hobbyists, small businesses, and educational institutions.

2. High Precision: They can accurately place components as small as 0201, ensuring precise assembly even for complex PCBs.

3. Automatic Feeders: Support for various feeder types, such as tape reel and vibrating feeders, allows for efficient component handling.

4. Vision Systems: Equipped with cameras that aid in component recognition and placement accuracy.

5. User-Friendly Software: Many models offer intuitive programming interfaces that simplify the setup and operation process.

Benefits for Small-Scale Production

Efficiency and Speed

- Automated Process: Automating the component placement process significantly increases production speed compared to manual assembly. For instance, machines like the Desktop SMT Ultra can achieve placement speeds of up to 3,000 components per hour (CPH), making them highly efficient for small-scale production[2].

- Reduced Labor Costs: By automating the placement process, businesses can reduce labor costs associated with manual assembly, leading to a rapid return on investment[1].

Accuracy and Quality

- High Precision Placement: Desktop SMD pick and place machines ensure accurate placement of components, reducing errors and improving overall product quality.

- Consistency: Consistent placement quality is maintained across all units, which is crucial for small-scale production where each unit counts.

Flexibility and Versatility

- Component Variety: These machines can handle a wide range of SMD components, from small packages like 0201 to larger components such as QFN and BGA[3].

- Adaptability: They are suitable for both prototyping and small batch production, making them versatile tools for various production needs.

Practical Applications in Small-Scale Production

Prototyping

- Rapid Prototyping: Desktop SMD pick and place machines facilitate quick turnaround times for prototype assembly, allowing for faster design iteration and testing.

- Precision Prototyping: Ensures that prototypes are assembled with high accuracy, which is critical for testing and validation.

Small Batch Production

- Efficient Production: These machines enable small businesses to produce batches of PCBs efficiently, meeting customer demands without the need for large-scale equipment.

- Cost-Effective: Offers a cost-effective solution for small-scale production, as they require less space and capital investment compared to industrial-scale machines[1].

Educational and Research Settings

- Teaching and Training: In educational settings, these machines provide hands-on experience with automated assembly processes, teaching students about SMT technology and its applications.

- Research and Development: Researchers can use these machines to quickly assemble and test new PCB designs, facilitating innovation in electronics.

Choosing the Right Desktop SMD Pick and Place Machine

When selecting a desktop SMD pick and place machine for small-scale production, several factors should be considered:

1. Production Capacity: Ensure the machine can meet your production needs in terms of components placed per hour.

2. Component Range: Choose a machine that can handle the types and sizes of components you work with.

3. Space and Budget: Consider the machine's size and cost to ensure it fits within your available space and budget.

4. Ease of Use: Opt for a machine with user-friendly software and programming options.

Advanced Features and Technologies

Vision Systems

- Component Recognition: Advanced vision systems enable machines to recognize and correctly orient components, ensuring accurate placement.

- Real-Time Feedback: Some machines provide real-time feedback on component placement, allowing for immediate adjustments if needed.

Auto Nozzle Changers

- Efficiency: Machines equipped with auto nozzle changers can handle various component sizes without manual intervention, increasing production efficiency.

- Versatility: This feature allows a single machine to handle a wide range of components, making it versatile for different production tasks.

Comparison with Large-Scale Machines

While desktop SMD pick and place machines are ideal for small-scale production, they differ significantly from large-scale machines used in high-volume manufacturing. Large machines are designed to handle thousands of components per hour and are equipped with numerous feeders, making them suitable for complex and high-volume production runs[7]. However, for small businesses or prototyping environments, the compact size and lower cost of desktop machines make them a more practical choice.

Future Developments and Trends

The future of desktop SMD pick and place machines looks promising, with ongoing advancements in technology expected to enhance their capabilities further. Trends include improved precision, increased automation, and more user-friendly interfaces. As electronics manufacturing continues to evolve, these machines will play a crucial role in enabling small-scale producers to innovate and compete effectively in the market.

Conclusion

In conclusion, desktop SMD pick and place machines are highly suitable for small-scale production. They offer a balance of efficiency, precision, and cost-effectiveness that makes them ideal for prototyping and small batch assembly. By automating the component placement process, these machines can significantly enhance production speed and quality, making them a valuable asset for small businesses and hobbyists alike.

Frequently Asked Questions

1. What is the typical placement speed of a desktop SMD pick and place machine?

A desktop SMD pick and place machine can achieve placement speeds ranging from a few hundred to several thousand components per hour (CPH), depending on the model. For example, the Desktop SMT Ultra can place up to 3,000 CPH[2].

2. Can desktop SMD pick and place machines handle large components?

While they are primarily designed for SMD components, some models can handle larger components like QFN and BGA. However, the maximum component size and type vary by machine model[3].

3. How do I program a desktop SMD pick and place machine?

Programming typically involves using software to create a placement file, which can be uploaded to the machine. Some machines also support manual programming via the front panel[6].

4. Are desktop SMD pick and place machines suitable for high-volume production?

These machines are generally better suited for small-scale production and prototyping. For high-volume production, larger industrial machines are typically more efficient and cost-effective[7].

5. What are the key factors to consider when choosing a desktop SMD pick and place machine?

Key factors include production capacity, component range, machine size, budget, and ease of use. It's important to ensure the machine meets your specific production needs and fits within your available resources.

Citations:

[1] https://www.hct-smt.com/blog/revolutionizing-electronics-manufacturing-with-mini-smt-pick-and-place-machines

[2] https://desktopequip.com/desktop-smt-ultra/

[3] https://www.neodensmt.com/other-products/desktop-smt-pick-and-place-machine.html

[4] https://www.hct-smt.com/products/general-smt-pick-and-place-machine/hct-t100-small-4-heads-smd-pick-and-place-machine

[5] https://www.tronstol.com/products/pick-and-place-machine/

[6] https://www.sztech-smt.com/product/desktop-pick-and-place-machine/

[7] https://www.zjyingxing.com/info/what-is-the-difference-between-a-desktop-smtma-94603292.html

[8] https://www.alibaba.com/showroom/smt-desktop-pick-and-place-machine.html

[9] https://pickandplace-neoden.en.made-in-china.com/product/UBemMyuvZRrb/China-Desktop-SMD-Pick-and-Place-Machine-SMT-Pick-and-Place-Machine-Neoden3V-Advanced.html

[10] https://www.elektormagazine.com/news/desktop-pick-and-place-brings-smt-line-in-house

[11] https://resources.pcb.cadence.com/blog/2024-pick-and-place-machine

[12] https://neodenusa.com/neoden-4-smt-pick-and-place-machine/

[13] https://www.machinedesign.com/markets/robotics/article/21122266/10-benefits-of-using-a-pick-and-place-machine

[14] https://en.wikipedia.org/wiki/Pick-and-place_machine

[15] https://www.charmhigh-tech.com/quality-7840267-29-feeders-2-heads-chmt48va-desktop-automatic-smd-smt-pick-and-place-machine-double-vision-camera

[16] https://www.eevblog.com/forum/manufacture/advice-on-a-desktop-pick-and-place-machine-under-$2500/

[17] https://www.neodensmt.com/other-products/smt-pick-and-place-machine-for-led-assembly.html

[18] https://www.zjyingxing.com/info/what-are-the-advantages-of-advanced-smt-machin-82695955.html

[19] https://www.pcbunlimited.com/t/smt-equipment/pick-and-place

[20] https://www.neodensmt.com/other-products/desktop-smd-pick-and-place-machine.html