Content Menu

● The Importance of Specialized Services

● Types of Specialized Services for Moving SMT Equipment

>> 1. Full-Service Relocation Companies

>> 2. Equipment Manufacturers' Services

>> 3. Specialized Logistics Providers

>> 4. Asset Management and Redeployment Services

● The Process of Moving Used SMT Equipment

>> 1. Pre-Move Assessment and Planning

>> 2. Preparation and Packing

>> 3. Transportation

>> 4. Reinstallation and Testing

● Challenges in Moving Used SMT Equipment

>> Fragility of Components

>> Size and Weight

>> Precision Requirements

>> Environmental Concerns

>> Regulatory Compliance

● Best Practices for Moving Used SMT Equipment

● The Impact of Technology on SMT Equipment Relocation

>> IoT and Remote Monitoring

>> 3D Scanning and Modeling

>> Virtual Reality (VR) Planning

>> Predictive Analytics

● The Future of SMT Equipment Relocation Services

● Conclusion

● FAQ

>> 1. How long does it typically take to move SMT equipment?

>> 2. What are the main risks involved in moving used SMT equipment?

>> 3. How can I ensure my SMT equipment is properly insured during a move?

>> 4. What should I look for when choosing a service to move my SMT equipment?

>> 5. How can I minimize downtime when moving my SMT production line?

● Citations:

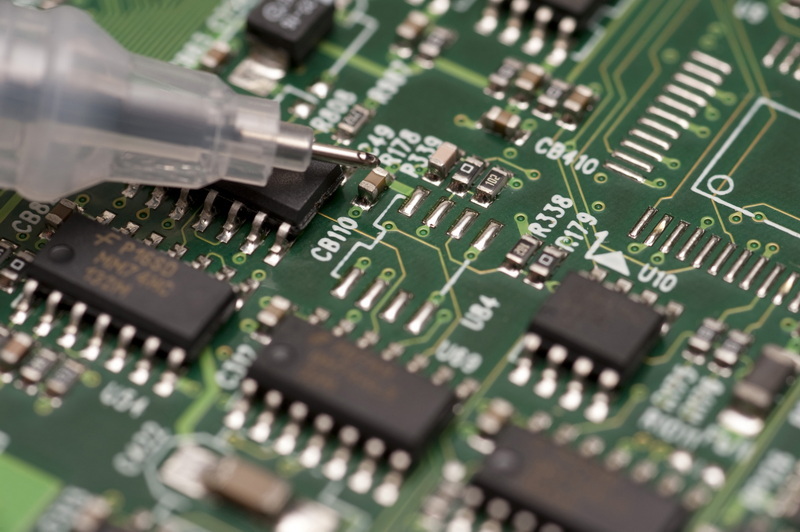

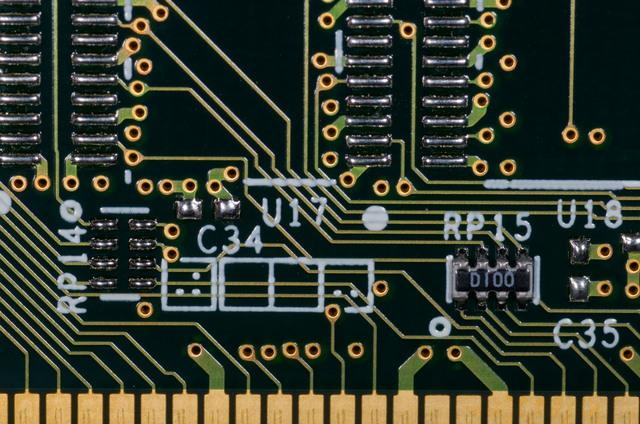

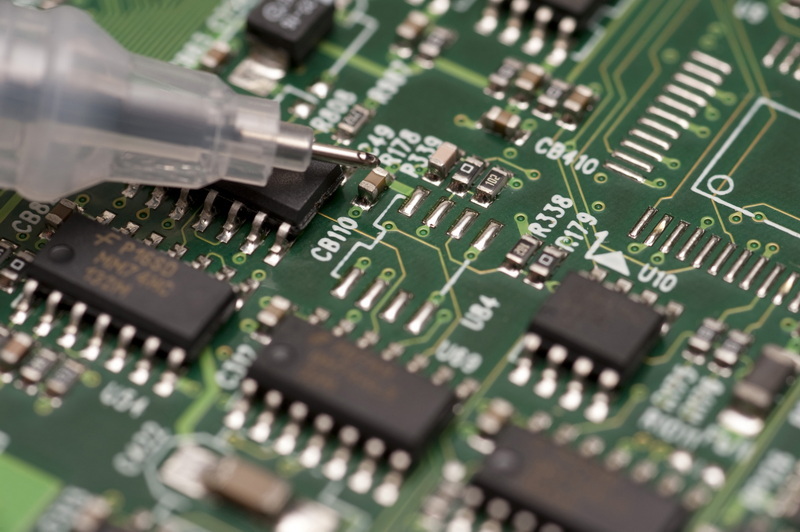

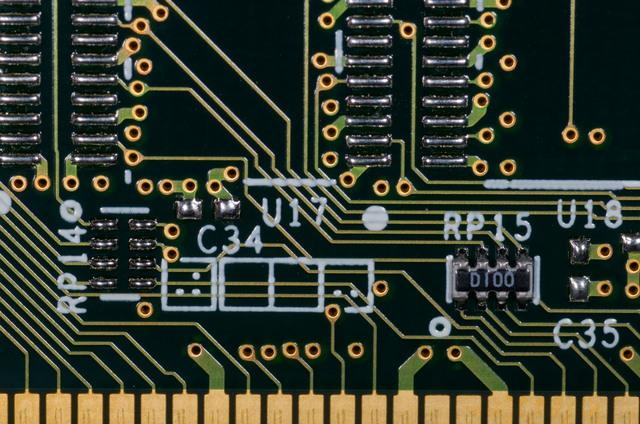

In the ever-evolving world of electronics manufacturing, Surface Mount Technology (SMT) equipment plays a crucial role in producing high-quality printed circuit boards (PCBs). As companies grow, downsize, or relocate, the need to move used SMT equipment becomes a significant consideration. This article explores the specialized services available for moving used PCB SMT manufacturing equipment, the challenges involved, and the best practices to ensure a smooth transition.

The Importance of Specialized Services

Moving used SMT equipment is not a simple task. These machines are often delicate, expensive, and require expert handling to maintain their precision and functionality. Specialized services for moving used PCB SMT manufacturing equipment are essential for several reasons:

1. Expertise: Professionals with experience in handling SMT equipment understand the intricacies of each machine and can ensure proper disassembly, packaging, and reassembly.

2. Safety: SMT equipment can be heavy and unwieldy. Specialized movers have the right tools and techniques to move these machines safely, reducing the risk of injury to personnel and damage to the equipment.

3. Compliance: Many SMT machines contain sensitive components that may be subject to transportation regulations. Specialized services are familiar with these requirements and can ensure compliance during the move.

4. Efficiency: Experienced movers can complete the relocation process more quickly and efficiently than untrained personnel, minimizing downtime for your manufacturing operations.

Types of Specialized Services for Moving SMT Equipment

Several types of specialized services cater to the needs of companies looking to move their used PCB SMT manufacturing equipment:

1. Full-Service Relocation Companies

These companies offer end-to-end solutions for moving SMT equipment. Their services typically include:

- Pre-move planning and consultation

- Disassembly of equipment

- Custom crating and packaging

- Transportation (including international shipping if required)

- Reassembly at the new location

- Calibration and testing of equipment post-move

Full-service relocation companies often have experience with a wide range of SMT equipment brands and models, making them a versatile choice for manufacturers[1].

2. Equipment Manufacturers' Services

Some SMT equipment manufacturers offer their own relocation services. These can be particularly beneficial when moving high-end or specialized machines, as the manufacturer's technicians have intimate knowledge of the equipment. Services may include:

- Professional disassembly and reassembly

- Specialized packaging designed for their equipment

- Calibration and software updates

- Warranty maintenance or extension

While potentially more expensive, manufacturer services can provide peace of mind and may be necessary for maintaining equipment warranties[2].

3. Specialized Logistics Providers

These companies focus on the transportation aspect of moving SMT equipment. They offer:

- Custom crating and packaging solutions

- Specialized transportation methods (air-ride trucks, temperature-controlled containers)

- International shipping and customs clearance

- Insurance coverage for high-value equipment

Logistics providers are often a good choice for companies that can handle the disassembly and reassembly in-house but need expert help with the actual transportation[4].

4. Asset Management and Redeployment Services

For companies looking to not only move but also optimize their SMT equipment assets, these services offer:

- Equipment valuation

- Asset redeployment strategies

- Selling or purchasing used equipment

- Coordinating moves between multiple facilities

These services can be particularly useful for large corporations managing equipment across multiple sites or those undergoing significant restructuring[7].

The Process of Moving Used SMT Equipment

Moving used PCB SMT manufacturing equipment typically involves several key steps:

1. Pre-Move Assessment and Planning

Before any equipment is touched, a thorough assessment is conducted. This includes:

- Inventory of all equipment to be moved

- Evaluation of the current setup and the new location's requirements

- Development of a detailed moving plan and timeline

- Identification of any special requirements (e.g., clean room conditions, ESD protection)

2. Preparation and Packing

Proper preparation is crucial for protecting sensitive SMT equipment:

- Cleaning and decontamination of equipment if necessary

- Removal of any consumables or loose parts

- Application of anti-static and moisture-barrier materials

- Custom crating or packaging designed for each piece of equipment

3. Transportation

The actual move requires careful consideration:

- Selection of appropriate transportation methods (truck, air, sea)

- Securing necessary permits for oversized or specialized equipment

- Monitoring of equipment during transit (shock, temperature, humidity)

- Coordination of pickup and delivery times

4. Reinstallation and Testing

Once at the new location, the process continues:

- Unpacking and inspection for any damage

- Reassembly of equipment according to manufacturer specifications

- Recalibration and testing to ensure proper functionality

- Integration with existing systems at the new facility

Challenges in Moving Used SMT Equipment

Moving used PCB SMT manufacturing equipment comes with several challenges:

Fragility of Components

SMT equipment often contains delicate components that can be easily damaged during transport. Specialized packing materials and techniques are essential to protect these sensitive parts.

Size and Weight

Many SMT machines are large and heavy, requiring specialized lifting equipment and transportation methods. This can be particularly challenging when moving equipment between floors or in buildings with limited access.

Precision Requirements

SMT equipment relies on precise calibration for optimal performance. Even minor misalignments during the move can affect the equipment's functionality, necessitating expert handling and recalibration.

Environmental Concerns

Some SMT equipment is sensitive to temperature, humidity, and electrostatic discharge. Maintaining appropriate environmental conditions throughout the move is crucial.

Regulatory Compliance

When moving SMT equipment across borders, companies must navigate complex import/export regulations, particularly for equipment that may have dual-use capabilities.

Best Practices for Moving Used SMT Equipment

To ensure a successful move of used PCB SMT manufacturing equipment, consider the following best practices:

1. Start planning early: Begin the planning process well in advance of the move date to allow for thorough preparation and to address any unforeseen issues.

2. Choose experienced movers: Select a moving service with a proven track record in handling SMT equipment. Ask for references and case studies of similar moves.

3. Document everything: Create detailed inventories and condition reports for all equipment before the move. Take photographs to record the current state of the machines.

4. Invest in proper packaging: Use high-quality, custom-designed packaging materials to protect your equipment during transit.

5. Consider insurance: Obtain comprehensive insurance coverage for the full value of your equipment during the move.

6. Coordinate with IT: Ensure that any software or network requirements for the SMT equipment are addressed at the new location before the move.

7. Plan for downtime: Factor in the time required for disassembly, moving, reassembly, and recalibration when scheduling your production.

8. Involve equipment manufacturers: Consult with the original equipment manufacturers for advice on moving their specific machines and for any necessary technical support.

9. Prepare the new site: Ensure that the new location meets all the requirements for your SMT equipment, including power supply, compressed air, and environmental controls.

10. Train staff: If your team will be involved in any aspect of the move, provide thorough training on proper handling and safety procedures.

The Impact of Technology on SMT Equipment Relocation

Advancements in technology are making the process of moving used PCB SMT manufacturing equipment more efficient and reliable:

IoT and Remote Monitoring

Internet of Things (IoT) devices can be attached to SMT equipment during transit to monitor conditions such as temperature, humidity, and shock. This real-time data allows for immediate intervention if any issues arise during the move.

3D Scanning and Modeling

Before disassembly, 3D scanning technology can create detailed models of the equipment setup. These models can be invaluable for ensuring accurate reassembly at the new location.

Virtual Reality (VR) Planning

VR technology allows movers to virtually plan and simulate the entire moving process, identifying potential obstacles and optimizing the relocation strategy before any physical work begins.

Predictive Analytics

By analyzing data from previous moves, specialized moving services can use predictive analytics to anticipate potential issues and develop more accurate timelines and cost estimates for future relocations.

The Future of SMT Equipment Relocation Services

As the electronics manufacturing industry continues to evolve, so too will the services for moving used PCB SMT manufacturing equipment. Some trends to watch for include:

- Increased use of robotics for handling and moving heavy equipment

- Development of more advanced, equipment-specific packaging solutions

- Greater integration of AI for optimizing move planning and execution

- Expansion of remote support capabilities for post-move setup and calibration

These advancements will likely lead to even more efficient and reliable relocation services for SMT equipment in the future.

Conclusion

Moving used PCB SMT manufacturing equipment is a complex process that requires specialized knowledge, skills, and equipment. The availability of specialized services for this task is crucial for ensuring that valuable SMT machines are relocated safely, efficiently, and with minimal disruption to manufacturing operations. By understanding the types of services available, the challenges involved, and best practices for equipment relocation, companies can make informed decisions and successfully navigate the process of moving their SMT assets.

As technology continues to advance, we can expect even more sophisticated and efficient methods for relocating SMT equipment. However, the fundamental principles of careful planning, expert handling, and attention to detail will remain essential for protecting these valuable assets during transit.

FAQ

1. How long does it typically take to move SMT equipment?

The time required to move SMT equipment can vary greatly depending on factors such as the amount and type of equipment, distance of the move, and complexity of the setup. A simple local move might be completed in a few days, while a large-scale international relocation could take several weeks or even months. It's essential to work closely with your chosen moving service to develop a realistic timeline that accounts for all aspects of the move, including preparation, transportation, and reinstallation.

2. What are the main risks involved in moving used SMT equipment?

The main risks in moving used SMT equipment include physical damage during transit, misalignment of precision components, exposure to adverse environmental conditions, and potential loss of calibration. Additionally, there's a risk of extended downtime if the move is not well-planned or executed. To mitigate these risks, it's crucial to work with experienced professionals who understand the intricacies of SMT equipment and can take appropriate precautions throughout the moving process.

3. How can I ensure my SMT equipment is properly insured during a move?

To ensure proper insurance coverage for your SMT equipment during a move, start by obtaining accurate valuations for all pieces of equipment. Work with an insurance provider experienced in covering high-value industrial equipment. Consider obtaining all-risk coverage that protects against a wide range of potential issues during transit. Be sure to understand the terms of the policy, including any exclusions or deductibles. Some specialized moving services may offer their own insurance options, which can be worth considering as they may have specific experience with SMT equipment moves.

4. What should I look for when choosing a service to move my SMT equipment?

When selecting a service to move your SMT equipment, consider the following factors:

- Experience specifically with SMT and PCB manufacturing equipment

- Knowledge of your particular brands and models of equipment

- Capability to handle international moves if required

- Comprehensive services including disassembly, packing, transportation, and reassembly

- Strong track record and positive references from similar clients

- Appropriate insurance and liability coverage

- Clear communication and detailed planning processes

- Ability to provide specialized packaging and handling for sensitive equipment

5. How can I minimize downtime when moving my SMT production line?

To minimize downtime when moving your SMT production line, consider these strategies:

- Plan the move during a scheduled maintenance period or low-production season

- Prepare the new location in advance, ensuring all necessary utilities and infrastructure are in place

- Use a phased approach, moving and setting up equipment in stages if possible

- Have spare parts and consumables ready at the new location

- Arrange for manufacturer technicians to be available for immediate post-move support

- Consider temporary outsourcing of production for critical components during the move

- Conduct thorough testing and calibration as soon as equipment is reinstalled

- Train operators in advance on any changes to the layout or workflow at the new location

Citations:

[1] https://smtdevices.com/about.html

[2] https://core-emt.com/service

[3] https://smtnet.com/library/index.cfm?fuseaction=browse_articles&start_at=296

[4] https://www.firstplacemachinery.com

[5] https://www.westernstatescat.com/service/specialized-services/

[6] https://www.globenewswire.com/en/news-release/2020/11/20/2130951/28124/en/China-SMT-Capacity-Study-and-Database-Directory-2020.html

[7] https://www.smtsalesgroup.com/smt-equipment-redeployment-services/

[8] https://www.buysmt.com

[9] https://www.businesswire.com/news/home/20201203005436/en/China-Surface-Mount-Technology-SMT-Capacity-Database-2020---ResearchAndMarkets.com

[10] https://www.adoptsmt.com/en/services/

[11] https://www.ddmnovastar.com/specialized-smt-equipment