Content Menu

● What are SMT Tray Feeders?

>> The Importance of Tray Feeders

● Types of SMT Tray Feeders

● Key Features of SMT Tray Feeders

● How to Select the Right SMT Tray Feeder

>> Component Characteristics

>> Production Volume

>> Machine Compatibility

● Potential Problems and Troubleshooting

● Maintenance and Best Practices

● Considerations for Choosing a Manufacturer

● The Future of SMT Tray Feeders

● Conclusion

● Frequently Asked Questions (FAQ)

>> Q1: What are SMT tray feeders used for?

>> Q2: What types of components can SMT tray feeders handle?

>> Q3: What are the different types of SMT tray feeders?

>> Q4: What should I consider when selecting an SMT tray feeder?

>> Q5: What are some common issues with SMT tray feeders?

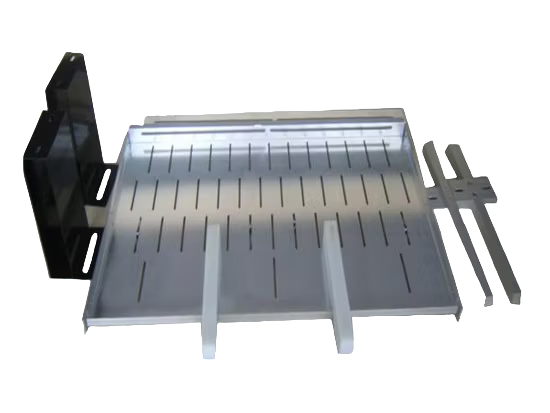

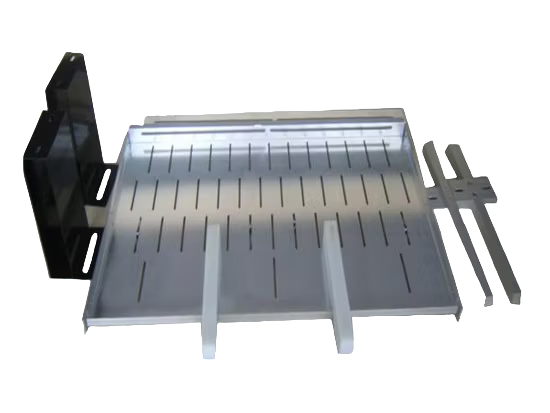

SMT tray feeders are specialized devices used in SMT assembly lines to supply electronic components that are packaged in trays or matrix trays. These trays typically hold components with larger sizes, odd shapes, or delicate structures that make tape and reel packaging impractical. The feeder automatically presents each tray to the pick-and-place machine, ensuring that the components are accurately positioned for pickup and placement onto the PCB.

The Importance of Tray Feeders

* Handling Odd-Form Components: Tray feeders are essential for components that cannot be easily packaged on tape and reel.

* Protecting Delicate Components: Trays provide a safe and secure method for handling fragile components, minimizing the risk of damage.

* Supporting Low-Volume Production: Tray feeders are ideal for small production runs or prototype assembly where tape and reel packaging may not be cost-effective.

Types of SMT Tray Feeders

SMT tray feeders come in various designs to accommodate different tray sizes and production requirements.

* Single-Layer Tray Feeders: These feeders hold a single tray and require manual tray replacement once the components are depleted[7].

* Multi-Layer Tray Feeders: These feeders can hold multiple trays, automatically switching between them to minimize downtime and increase component capacity[1].

* Automatic Tray Suppliers (ATS): These advanced systems offer automated tray exchange, further enhancing efficiency[3]. Yamaha ATS tray feeders, for example, are compatible with YRM20 pick & place machines[3].

Key Features of SMT Tray Feeders

* Precise Component Positioning: Ensures accurate component pickup and placement.

* Automated Tray Handling: Reduces manual intervention and increases throughput.

* Adjustable Settings: Accommodates different tray sizes and component types.

* Compatibility: Designed to integrate seamlessly with various SMT placement machines.

* Vibration Control: Dampens vibrations to protect delicate components.

How to Select the Right SMT Tray Feeder

Choosing the appropriate SMT tray feeder for your assembly line depends on several factors:

Component Characteristics

* Size and Shape: Select a feeder that can accommodate the size and shape of your components.

* Fragility: Choose a feeder that provides gentle handling to prevent damage.

* Tray Size: Ensure that the feeder is compatible with the size of your trays.

Production Volume

* Low-Volume: A single-layer tray feeder may be sufficient for small production runs.

* High-Volume: A multi-layer tray feeder or an automatic tray supplier (ATS) is recommended for high-volume production to minimize downtime.

Machine Compatibility

* SMT Placement Machine: Ensure that the feeder is compatible with your specific SMT placement machine model[3][7].

* Interface: Check that the feeder has the correct interface for communication and control.

Potential Problems and Troubleshooting

* Material Tray Stuck: Recheck the SMT feeder if the material tray is stuck[2].

* Feeder Doesn't Achieve Desired Output: The vibratory tray feeder may be too small for your desired feed-rate[4].

* Feeder Output is Inconsistent: This can be caused by several factors, including feeder misapplication or loose spring clamps[4].

Maintenance and Best Practices

* Regular Cleaning: Clean the feeder regularly to remove dust, debris, and contaminants.

* Inspection: Inspect the feeder for worn or damaged parts, such as belts and sensors.

* Proper Adjustment: Adjust the feeder settings to ensure optimal component presentation.

* Troubleshooting: Familiarize yourself with common problems and their solutions to minimize downtime[2][4].

Considerations for Choosing a Manufacturer

While the search results don't directly list SMT tray feeders manufacturer, here are factors to consider when selecting a supplier:

* Reputation and Experience: Choose a manufacturer with a proven track record in the SMT industry.

* Quality and Reliability: Look for feeders made with high-quality materials and robust construction.

* Support and Service: Ensure the manufacturer offers adequate technical support and service.

* Customization Options: A manufacturer that can customize tray feeders to fit specific needs.

The Future of SMT Tray Feeders

* Smart Integration: Integration of sensors and data analytics for real-time monitoring and predictive maintenance.

* Enhanced Automation: Development of fully automated tray handling systems for maximum efficiency.

* Flexible Designs: Designs that can accommodate a wider variety of tray sizes and component types.

Conclusion

SMT tray feeders are essential for handling odd-form and delicate components in SMT assembly. By understanding their features, benefits, and selection criteria, manufacturers can effectively integrate tray feeders into their SMT lines and optimize their production processes. Partnering with a reputable supplier is crucial for ensuring the reliability and performance of your tray feeder system.

Frequently Asked Questions (FAQ)

Q1: What are SMT tray feeders used for?

SMT tray feeders are used to supply electronic components that are packaged in trays to pick-and-place machines in SMT assembly lines[1][3][5].

Q2: What types of components can SMT tray feeders handle?

SMT tray feeders can handle a wide range of components, including larger components, odd-shaped components, and delicate components that are not suitable for tape and reel packaging[5].

Q3: What are the different types of SMT tray feeders?

The different types of SMT tray feeders include single-layer tray feeders, multi-layer tray feeders, and automatic tray suppliers (ATS)[1][3].

Q4: What should I consider when selecting an SMT tray feeder?

Consider component characteristics (size, shape, fragility), production volume, and machine compatibility when selecting an SMT tray feeder[3].

Q5: What are some common issues with SMT tray feeders?

Common issues include material tray stuck and inconsistent feeder output[2][4].