Introduction

In the rapidly evolving world of electronics, the efficiency of printed circuit board (PCB) assembly is paramount. One of the most significant advancements in this field is soldering surface mount technology (SMT). This method has revolutionized how electronic components are attached to PCBs, leading to faster production times, reduced costs, and improved performance. In this article, we will explore how surface mount soldering enhances PCB assembly efficiency, the benefits it offers, and the challenges it presents. We will also address common questions related to this technology.

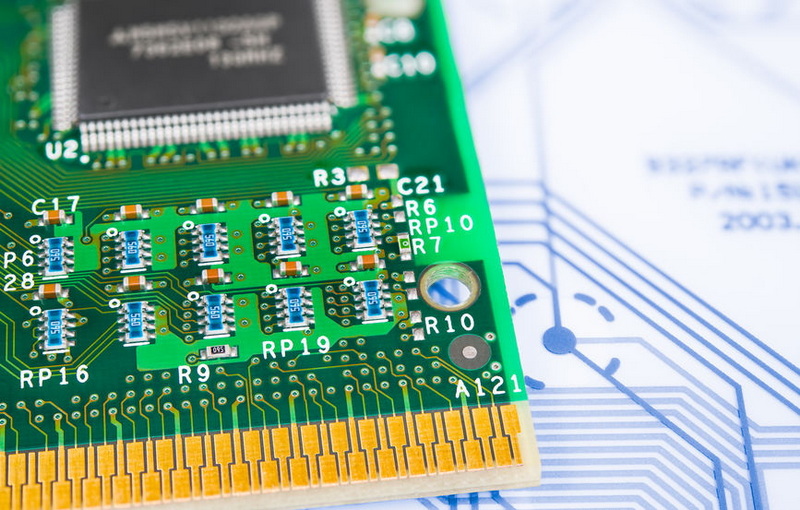

Understanding Surface Mount Technology

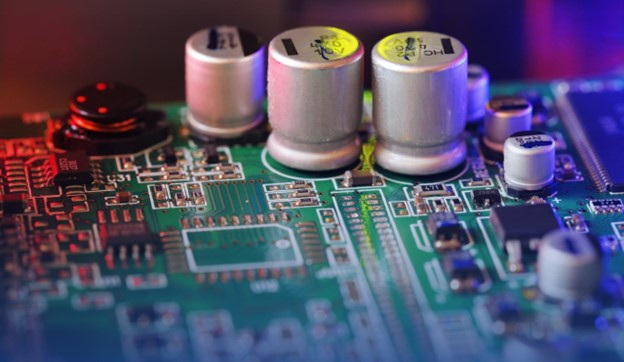

Surface mount technology (SMT) involves mounting electronic components directly onto the surface of a PCB rather than inserting them through holes, as in traditional through-hole technology. This method allows for a more compact design, enabling manufacturers to create smaller and more complex devices. The soldering process in SMT typically involves applying solder paste to the PCB, placing the components, and then using a reflow oven to melt the solder, creating a strong electrical and mechanical connection.

Advantages of Surface Mount Soldering

1. Increased Component Density

One of the primary advantages of soldering surface mount technology is the ability to increase component density on PCBs. SMT components are generally smaller than their through-hole counterparts, allowing for more components to be placed in a given area. This is particularly beneficial for modern electronic devices that require compact designs, such as smartphones and wearable technology. The ability to fit more components into a smaller space not only saves physical space but also allows for more complex functionalities within the same footprint.

2. Reduced Assembly Time

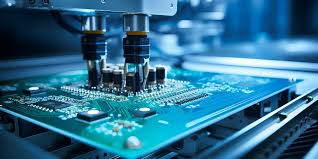

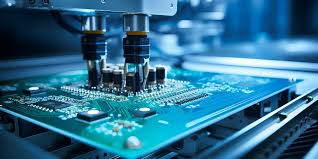

The automation of the SMT process significantly reduces assembly time. Automated pick-and-place machines can quickly and accurately position components on the PCB, followed by the reflow soldering process. This efficiency leads to shorter production cycles and the ability to meet tight deadlines in the competitive electronics market. The speed of automated systems also minimizes the risk of human error, ensuring that components are placed correctly every time.

3. Lower Production Costs

With the reduction in assembly time and the ability to use smaller components, manufacturers can lower production costs. SMT also requires less manual labor compared to through-hole soldering, further decreasing labor costs. Additionally, the smaller size of SMT components often results in lower material costs. The overall reduction in costs allows companies to offer competitive pricing for their products, which is crucial in a market where consumers are always looking for the best value.

4. Improved Electrical Performance

Surface mount soldering can enhance the electrical performance of PCBs. The shorter leads and smaller footprints of SMT components reduce parasitic inductance and capacitance, which can improve signal integrity and reduce electromagnetic interference (EMI). This is crucial for high-frequency applications where performance is critical. Improved electrical performance translates to better functionality and reliability in devices, which is essential for maintaining customer satisfaction.

5. Enhanced Reliability

The solder joints created through surface mount soldering are generally more reliable than those made with through-hole technology. The reflow process creates a uniform solder joint that is less prone to mechanical stress and fatigue. This reliability is essential for devices that must operate in harsh environments or under varying conditions. Additionally, the absence of through-holes reduces the risk of solder wicking, which can lead to weak joints.

6. Flexibility in Design

SMT allows for greater flexibility in PCB design. Designers can experiment with different layouts and configurations without being constrained by the need for through-holes. This flexibility enables the integration of advanced features and functionalities, such as multi-layer boards and complex routing, which are increasingly demanded in modern electronics.

7. Compatibility with Automated Testing

The compact nature of SMT components and the uniformity of solder joints make it easier to implement automated testing processes. Automated optical inspection (AOI) systems can quickly and accurately check for defects in solder joints and component placement, ensuring high-quality production. This capability is essential for maintaining the standards required in industries such as aerospace and medical devices, where reliability is non-negotiable.

Challenges of Surface Mount Soldering

While surface mount soldering offers numerous advantages, it also presents some challenges that manufacturers must address:

1. Complexity of Design

Designing PCBs for SMT can be more complex than for through-hole technology. Engineers must consider factors such as component placement, thermal management, and the potential for solder bridging. This complexity can lead to longer design times and increased costs if not managed properly. Additionally, the need for precise alignment and placement of components requires advanced design software and skilled engineers.

2. Soldering Defects

Common defects in surface mount soldering include insufficient solder, solder bridging, and tombstoning (where one end of a component lifts off the PCB). These defects can lead to failures in the final product, necessitating rigorous quality control measures during the assembly process. Manufacturers must implement strict inspection protocols and invest in training for their staff to minimize these issues.

3. Equipment Costs

The initial investment in SMT equipment, such as pick-and-place machines and reflow ovens, can be significant. However, many manufacturers find that the long-term savings in labor and material costs justify this investment. Additionally, as technology advances, the cost of SMT equipment continues to decrease, making it more accessible for smaller manufacturers.

4. Skill Requirements

While SMT can reduce the need for manual labor, it does require skilled technicians to operate the machinery and troubleshoot issues. Training staff to handle SMT processes effectively is essential for maintaining efficiency and quality. Continuous education and training programs can help ensure that employees are up-to-date with the latest technologies and best practices.

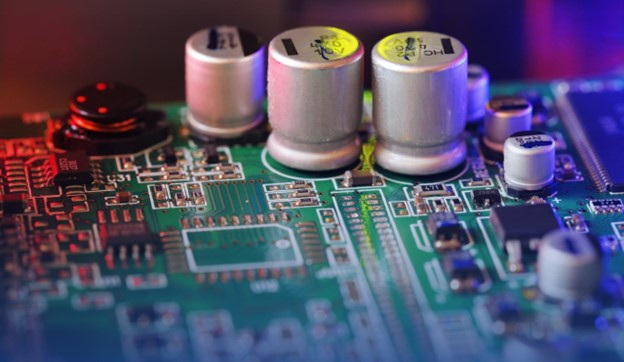

5. Thermal Management

The compact nature of SMT can lead to challenges in thermal management. As components are placed closer together, heat dissipation becomes a critical concern. Manufacturers must design PCBs with adequate thermal pathways and consider the thermal characteristics of components to prevent overheating and ensure reliable operation.

Future Trends in Surface Mount Soldering

As technology continues to advance, several trends are emerging in the field of surface mount soldering that will further enhance PCB assembly efficiency:

1. Miniaturization of Components

The trend towards smaller and more powerful electronic devices is driving the miniaturization of components. As manufacturers develop smaller SMT components, the ability to create even more compact and efficient PCBs will increase. This trend will enable the development of new applications in areas such as IoT (Internet of Things) and wearable technology.

2. Advanced Materials

The use of advanced materials in soldering processes is becoming more common. New solder alloys and substrates can improve the performance and reliability of solder joints, particularly in high-temperature and high-frequency applications. Manufacturers are increasingly exploring these materials to enhance the capabilities of their products.

3. Integration of AI and Machine Learning

The integration of artificial intelligence (AI) and machine learning into the SMT process is set to revolutionize PCB assembly. These technologies can optimize production processes, predict maintenance needs, and improve quality control by analyzing data from production lines. This will lead to even greater efficiency and reliability in surface mount soldering.

4. Sustainability Initiatives

As environmental concerns grow, manufacturers are focusing on sustainability in their production processes. This includes the development of lead-free soldering materials and the implementation of recycling programs for electronic waste. Sustainable practices not only benefit the environment but can also enhance a company's reputation and appeal to eco-conscious consumers.

5. Increased Automation

The trend towards increased automation in manufacturing is expected to continue. As technology advances, more processes within SMT will become automated, further reducing labor costs and increasing efficiency. This shift will allow manufacturers to scale production while maintaining high quality and consistency.

Conclusion

In conclusion, soldering surface mount technology has dramatically improved PCB assembly efficiency through increased component density, reduced assembly time, lower production costs, improved electrical performance, and enhanced reliability. While there are challenges associated with SMT, the benefits far outweigh the drawbacks, making it a preferred choice in modern electronics manufacturing. As technology continues to advance, the role of surface mount soldering will only become more critical in the quest for efficient and reliable electronic devices.

Related Questions

1. What is the difference between surface mount technology and through-hole technology?

Surface mount technology (SMT) involves mounting components directly on the surface of a PCB, while through-hole technology requires components to be inserted into holes drilled in the PCB. SMT allows for smaller, denser designs and is generally more efficient for automated assembly.

2. How does the reflow soldering process work?

Reflow soldering involves applying solder paste to the PCB, placing the components, and then heating the assembly in a reflow oven. The heat melts the solder, creating a strong bond between the components and the PCB as it cools.

3. What are common defects in surface mount soldering?

Common defects include insufficient solder, solder bridging, and tombstoning. These issues can lead to electrical failures and require careful inspection and quality control during the assembly process.

4. How can manufacturers improve the reliability of SMT solder joints?

Manufacturers can improve reliability by ensuring proper solder paste application, optimizing reflow profiles, and using high-quality components. Regular maintenance of soldering equipment also plays a crucial role in maintaining quality.

5. What are the benefits of using automated pick-and-place machines in SMT?

Automated pick-and-place machines increase the speed and accuracy of component placement, reduce labor costs, and minimize human error. This automation is essential for achieving high efficiency in PCB assembly.